Method for innocent treatment of aluminum electrolysis anode carbon residue and recovery of electrolyte

A technology of harmless treatment and aluminum electrolysis anode, applied in the field of aluminum electrolysis, can solve the problems of low electrolyte recovery rate, complex process flow, low electrolyte purity, etc., achieve environmental protection benefits and economic benefits, short process flow, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

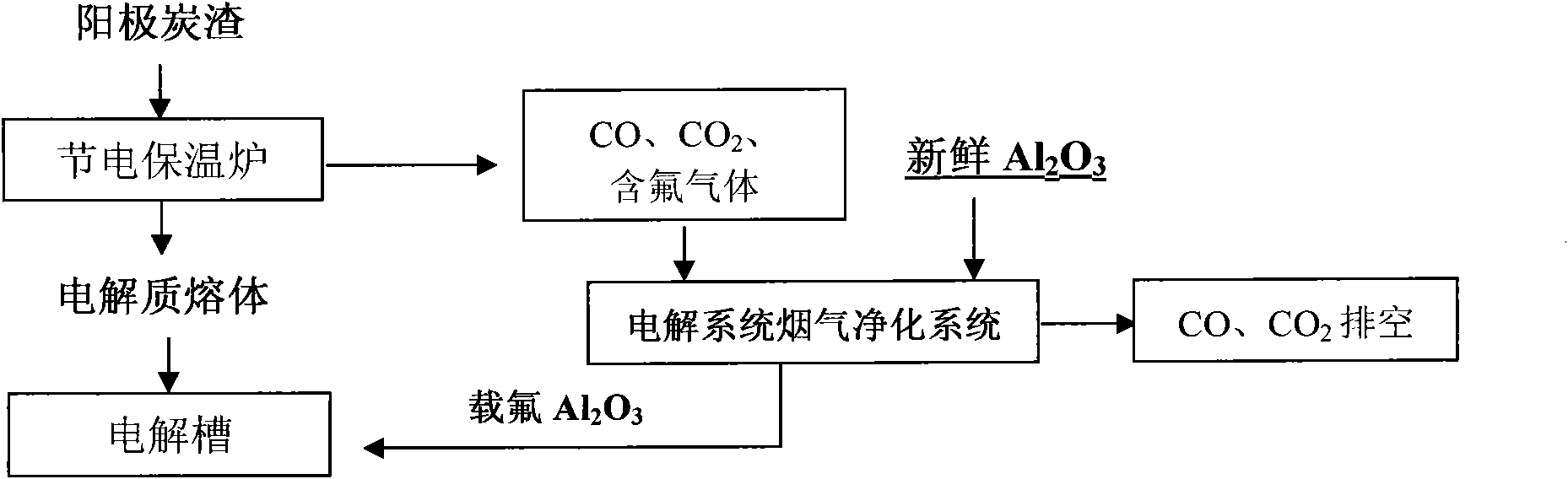

[0014] Add 624kg of anode carbon slag salvaged from the aluminum electrolytic cell into the energy-saving heat preservation furnace and heat it to 800°C to completely burn the combustibles in the carbon slag. The fluoride discharged during the smelting process is connected to the electrolytic flue gas purification system for recycling, and the electrolyte is harmlessly recovered.

[0015] Implementation results: 340kg of electrolyte was obtained by smelting and recovery, and electrolyte components: F: 40.9%; Al 2 o 3 : 28.37%; Na 2 O: 19.8%; CaO: 2.0%, the impurity content meets the requirements of the electrolyte.

Embodiment 2

[0017] 856kg of anode carbon slag salvaged from the aluminum electrolytic cell is added to the energy-saving heat preservation furnace and heated to 1500°C to completely burn the combustibles in the carbon slag. The fluoride discharged during the smelting process is connected to the electrolytic flue gas purification system for recycling, and the electrolyte is recovered harmlessly.

[0018] Implementation results: 435kg of electrolyte was obtained by smelting and recycling, among the electrolyte components: F: 42.97%; Al 2 o 3 : 27.37%; Na 2 O: 20.5%; CaO: 2.5%, the impurity content meets the requirements of the electrolyte.

Embodiment 3

[0020] Add 424kg of anode carbon slag salvaged from the aluminum electrolytic cell into the energy-saving heat preservation furnace and heat it to 1200°C to completely burn the combustibles in the carbon slag. The fluoride discharged during the smelting process is connected to the electrolytic flue gas purification system for recycling, and the electrolyte is recovered harmlessly.

[0021] Implementation results: 219kg of electrolyte was obtained by smelting and recycling, among the electrolyte components: F: 40.97%; Al 2 o 3 : 29.37%; Na 2 O: 21.5%; CaO: 3.5%, the impurity content meets the requirements of the electrolyte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com