Aluminum electrolysis waste tank lining harmless treatment device and treatment method

A technology of harmless treatment and waste tank lining, which is applied in the direction of solid waste removal, etc., can solve the problems of low treatment efficiency, and achieve the effect of high treatment efficiency, good effect and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

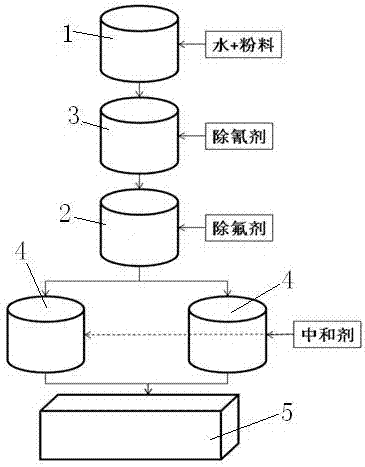

Embodiment 1

[0038] (1) The aluminum electrolytic waste tank lining is crushed and pulverized into powder.

[0039] (2) The first step: add water and powder to the reaction chamber of this step, the mass ratio of water and powder is 1:1, the reaction time of this step is 30min, the adding speed of water is 20m³ / h, the powder The feeding rate is 20t / h, and the first step requires a reaction chamber whose volume is not less than 30m³.

[0040](3) The second step: Add cyanide-removing agent bleaching powder to the reaction chamber of this step, the addition amount is 1.5% of the powder mass, the reaction time of this step is 30min, the adding speed of bleaching powder is 300Kg / h, and the slurry pouring speed It is 20m³ / h, and the second step requires a reaction chamber with a volume of not less than 30m³.

[0041] (4) The third step: Add quicklime, a defluoridation agent, to the reaction chamber of this step, the amount added is 5% of the mass of the powder, the reaction time of this step is...

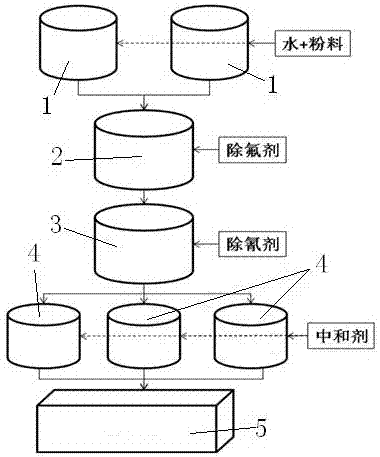

Embodiment 2

[0049] (1) The aluminum electrolytic waste tank lining is crushed and pulverized into powder.

[0050] (2) The first step: add water and powder to the reaction chamber of this step, the mass ratio of water and powder is 5.0:1.0, the reaction time of this step is 60min, and the adding speed of water in each reaction chamber is 20m³ / h, powder feeding speed 4t / h, the first step requires two reaction chambers, the volume of which is not less than 30m³.

[0051] (3) The second step: add defluoridation agent slaked lime to the reaction chamber of this step, the addition amount is 15% of the powder mass, the reaction time of this step is 30min, the lime addition speed is 1.2t / h, and the slurry is poured The feed rate is 40m³ / h. The second step requires a reaction chamber with a volume of not less than 40m³. The two reaction chambers in the first step are simultaneously poured into one reaction chamber in the second step.

[0052] (3) The third step: add cyanide-removing agent bleach...

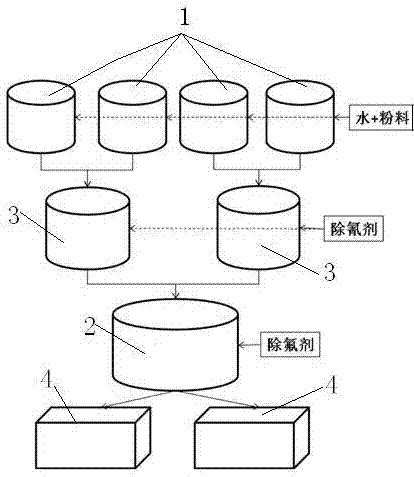

Embodiment 3

[0060] (1) The aluminum electrolytic waste tank lining is crushed and pulverized into powder.

[0061] (2) The first step: add water and powder to the reaction chamber of this step, the mass ratio of water to powder is 10:1, the reaction time of this step is 120min, and the adding speed of water in each reaction chamber is 15m³ / h, powder feeding speed 1.5t / h, the first step requires four reaction chambers, the volume of which is not less than 40m³.

[0062] (3) The second step: add cyanide-removing agent bleaching powder to the reaction chamber of this step, the addition amount is 8.0% of the powder mass, the reaction time of this step is 60min, and in each reaction chamber, the adding speed of bleaching powder is 240Kg / h, the slurry pouring speed is 30m³ / h, the second step requires two reaction chambers, and the volume of the reaction chamber is not less than 50m³, and the two reaction chambers in the first step are poured into one reaction chamber in the second step at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com