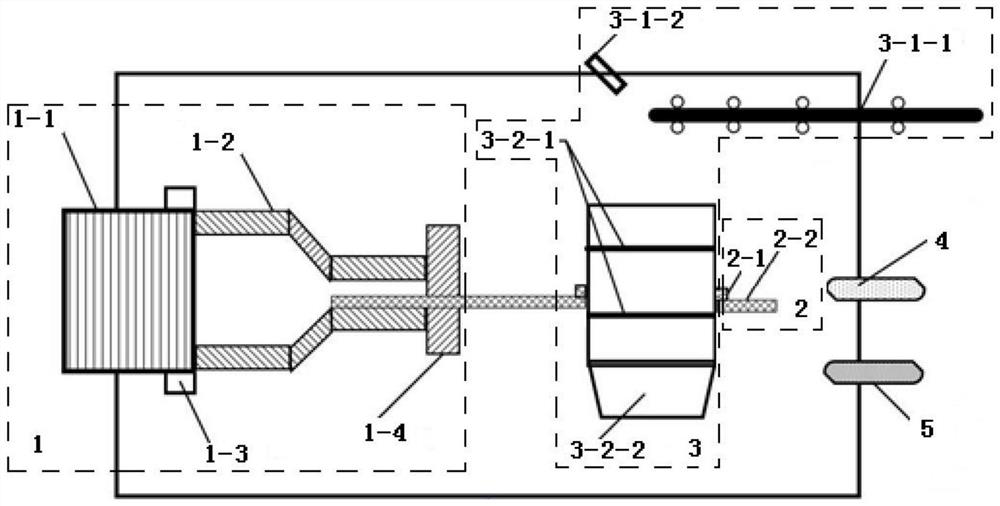

An ultrasonic atomization device and method for preparing spherical metal powder

An ultrasonic atomization and metal technology is applied in the field of ultrasonic atomization device and the preparation of spherical metal powder. Active metal and air contact reaction, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

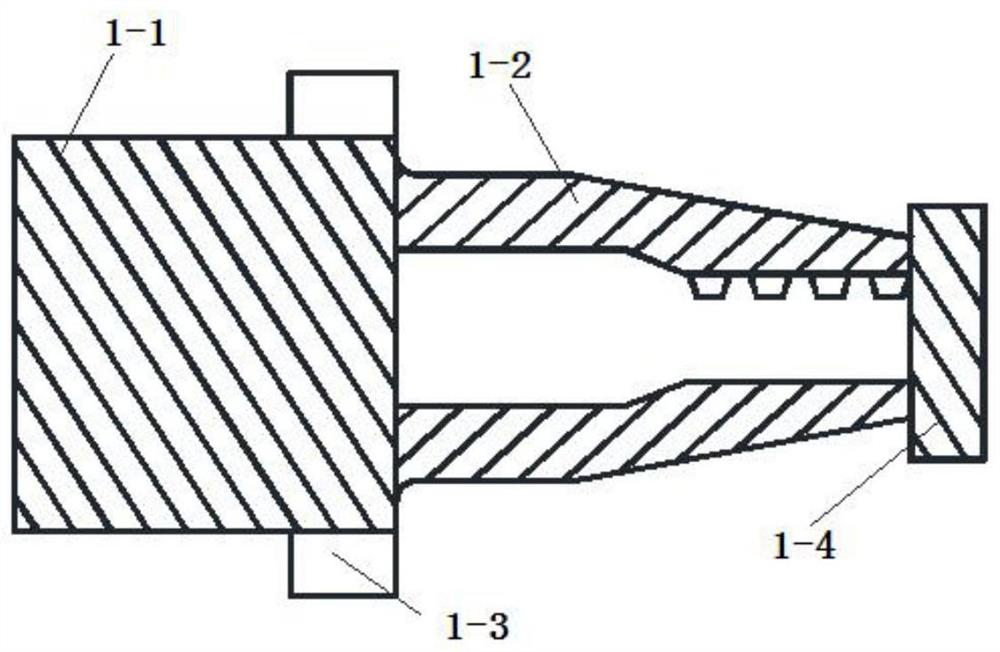

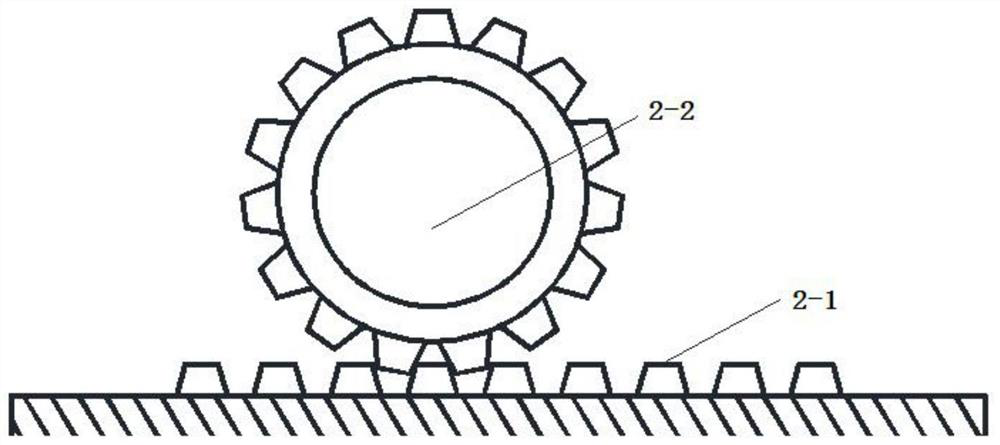

[0078] Select 17-4 stainless steel as the metal base material, use laser melting (the heat source generator is a YAG laser), the laser energy is 20kW, the laser frequency is 20kHz, the laser spot diameter is 100μm, and the metal base metal bar (diameter is 40mm) is set by The conveying system with rollers is used for transmission, and the feeding speed of the metal base material is 30mm / min; the chamber of the device is vacuumized to a pressure of 0.1Pa through the vacuum channel to prepare the spherical metal powder by ultrasonic atomization, and then the chamber is filled with inert gas through the inert gas channel. The pressure of nitrogen gas is 0.1MPa, and the flow rate of nitrogen gas charged to the atomization chamber is kept at 20m 3 / min, the heat source starts to work to melt the metal base metal bar, the material of the horn is 45# steel, the frequency of the mechanical vibration of the rack and pinion is 25kHz, the speed of the mesh screen is set to 60rpm, the metal...

Embodiment 2

[0083] 304 stainless steel is selected as the metal base material, and laser melting is adopted (the heat source generator is a YAG laser), the laser energy is 20kW, the laser frequency is 20kHz, the diameter of the laser spot is 100μm, and the metal base material bar (diameter is 40mm) is provided with rollers. The feeding speed of the metal base material is 30mm / min; the chamber of the device to prepare spherical metal powder is vacuumized by ultrasonic atomization through the vacuum channel to the pressure of 0.1Pa, and then the chamber is filled with inert gas nitrogen through the inert gas channel To the pressure of 0.1MPa, the flow rate of nitrogen filling into the atomization chamber is kept at 20m 3 / min, the heat source starts to work to melt the metal base metal bar, the material of the horn is 45# steel, the frequency of the mechanical vibration of the rack and pinion is 25kHz, the speed of the mesh screen is set to 60rpm, the metal droplets are rotated by centrifuga...

Embodiment 3

[0088] The GH4169 nickel-based superalloy is selected as the metal base material, and laser melting is adopted (the heat source generator is a YAG laser), the laser energy is 20kW, the laser frequency is 20kHz, the diameter of the laser spot is 100μm, and the metal base metal bar (diameter is 25mm) consists of A conveyor system equipped with rollers is provided for transmission, and the feeding speed of the metal base material is 50mm / min; the chamber of the device for preparing spherical metal powder is vacuumized to a pressure of 0.1Pa through ultrasonic atomization through a vacuum channel, and then filled into the chamber through an inert gas channel Inert gas nitrogen to the pressure of 0.1MPa, and the flow rate of nitrogen filling into the atomization chamber is kept at 20m 3 / min, the heat source starts to work to melt the metal base metal bar, the material of the horn is 45# steel, the frequency of the mechanical vibration of the rack and pinion is 25kHz, the speed of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com