Novel process of liquid phase impact diffusion welding for aluminium-based composite material

An aluminum-based composite material and diffusion welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems affecting joint quality, improvement, and long welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

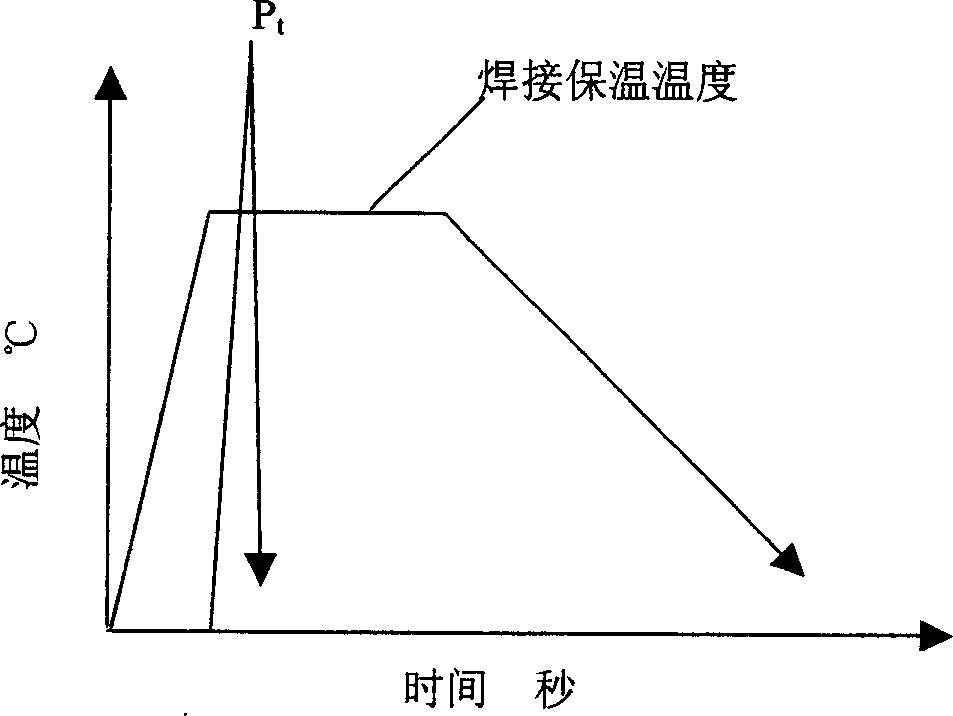

Embodiment Construction

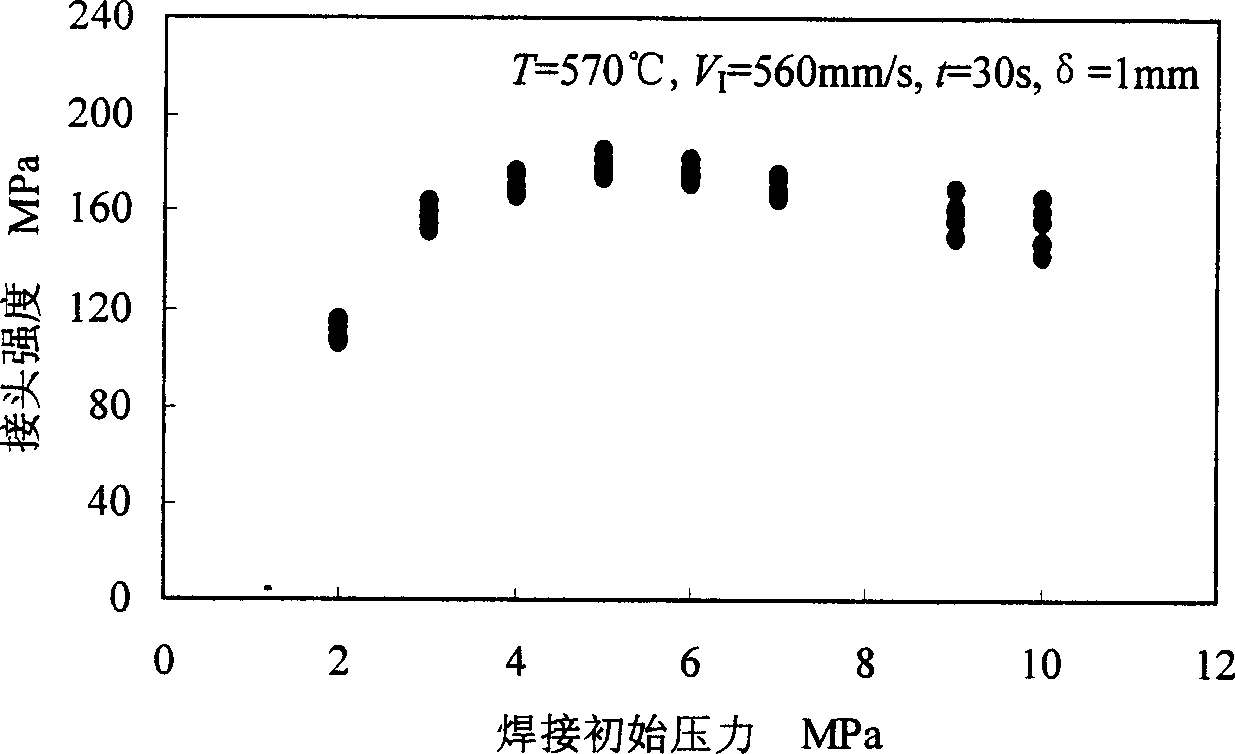

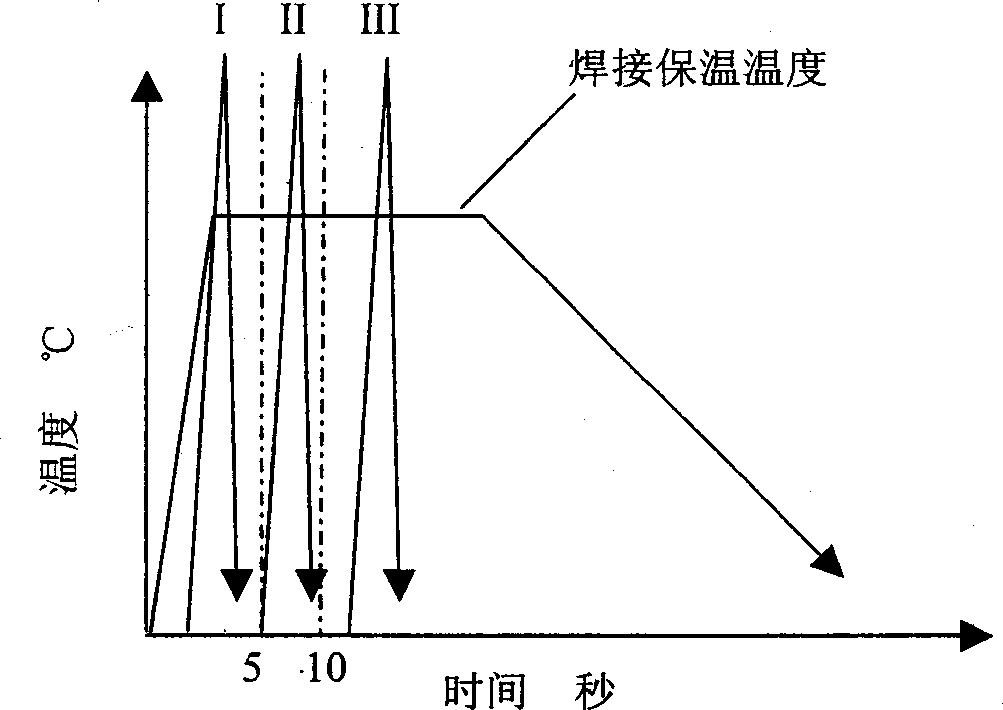

[0038] 1. The aluminum-based composite material SiCp / ZL101 is welded by the new process of liquid-phase impact diffusion welding of aluminum-based composite materials proposed by the present invention. The thickness of the workpiece is 1mm, and the average size of SiC particles of the reinforcing material is 12mm, and they are distributed in granular form. Butt joints are used. Vacuum degree 4×10 -1 Pa, the welding holding temperature is 568-572°C, which corresponds to the liquid volume fraction of the aluminum-based composite material matrix of 20-35%, the initial welding pressure is 5Mpa, the welding temperature holding time is 30 seconds, and the impact pressure is 80-100Mpa. The impact velocity is applied within 5-10 seconds after the welding temperature starts to keep warm, and the impact velocity application time interval is 0.0001-0.01 seconds. After welding, the joint strength is 179Mpa, which is close to the base metal strength of 74.6%, and the deformation is less tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com