Novel method for configuring and connecting steel ropes

A connection method and steel wire rope technology, which can be applied to other household appliances, household appliances, applications, etc., can solve problems such as increased wire rope insertion resistance, poor safety and reliability, and sudden belt breakage accidents, so as to improve the quality and safety of joints, and improve Effect of service life and improvement of interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

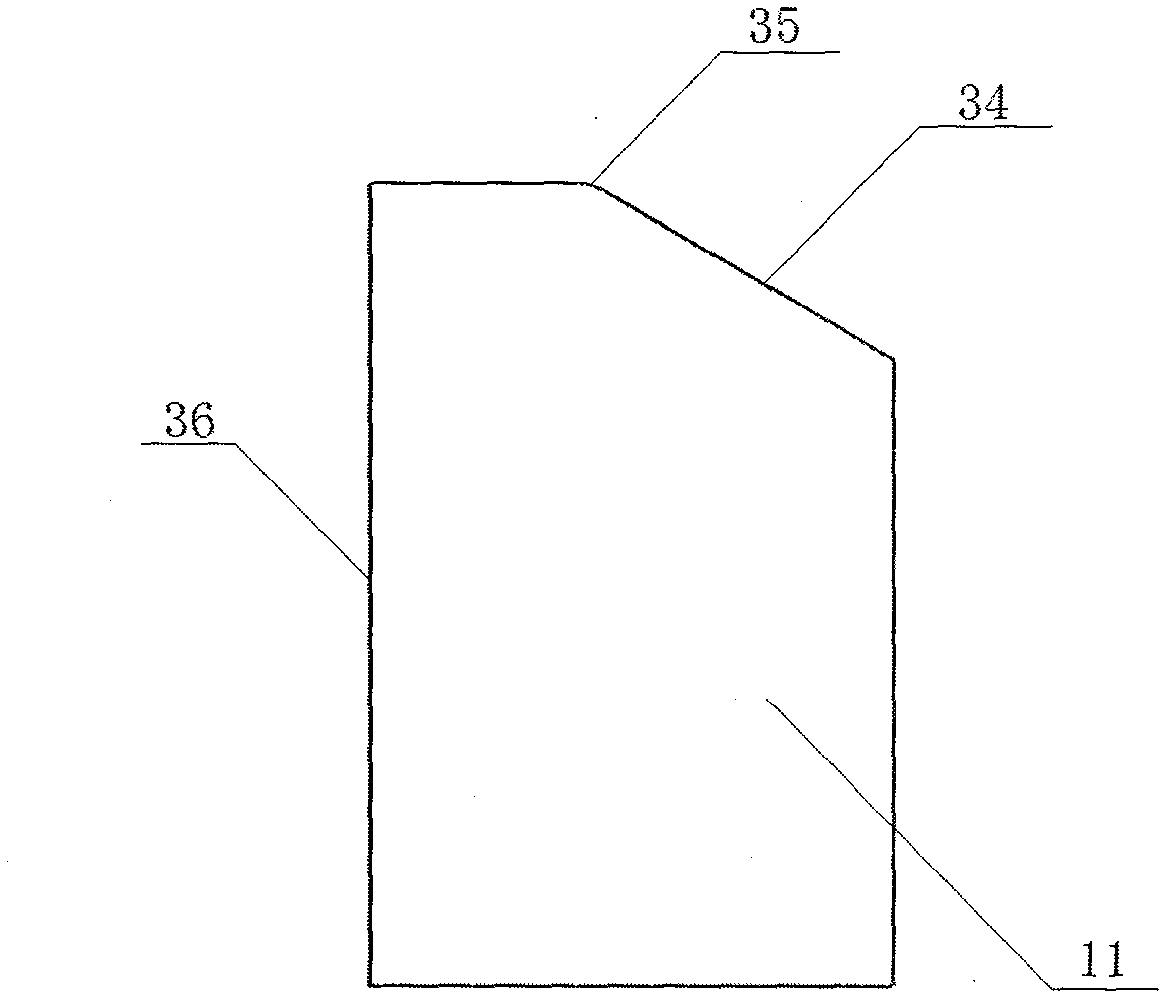

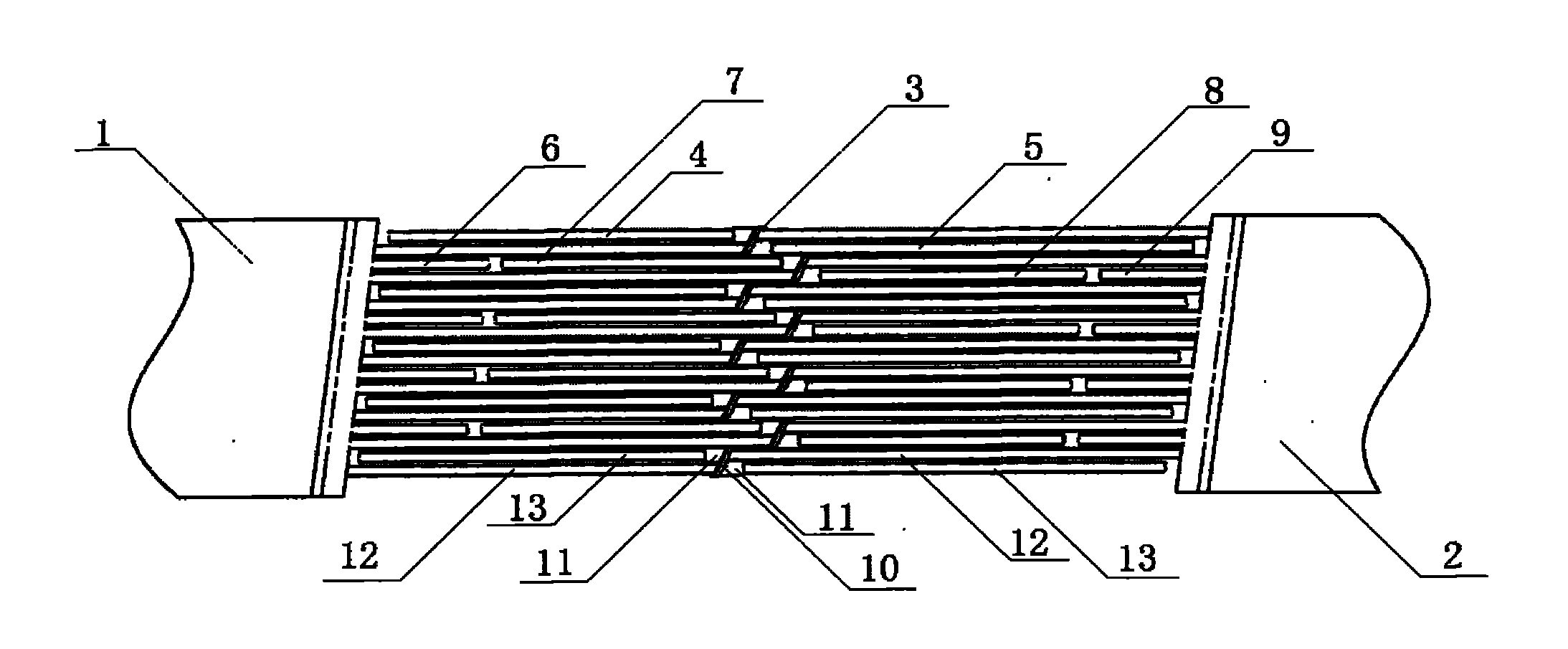

[0023] figure 1 The schematic diagram of the new type of steel wire rope arrangement and combination at the interface of the steel cord conveyor belt and the wire rope connection lock (3) is shown in , in which the new type of wire rope arrangement is suitable for lap joints above the second level, image 3 The old-fashioned two-stage lapping method is shown in the figure. Two steel wire ropes protrude from the second end of the conveyor belt (2), one of which is equal to the length of the joint, and the other is half the length of the joint. 1 / 2 long steel rope (16) of end is relative, inserts a long steel rope from conveyor belt first end, so repeatedly the ratio of its steel rope staggered arrangement is 66%. Figure 4 The old-fashioned three-stage lapping method is shown in the middle. The steel wire ropes are divided into three types: long, medium and short. One-third of the long steel wire rope protruding from end A is opposite, and one-third of the long steel wire rope...

Embodiment approach 2

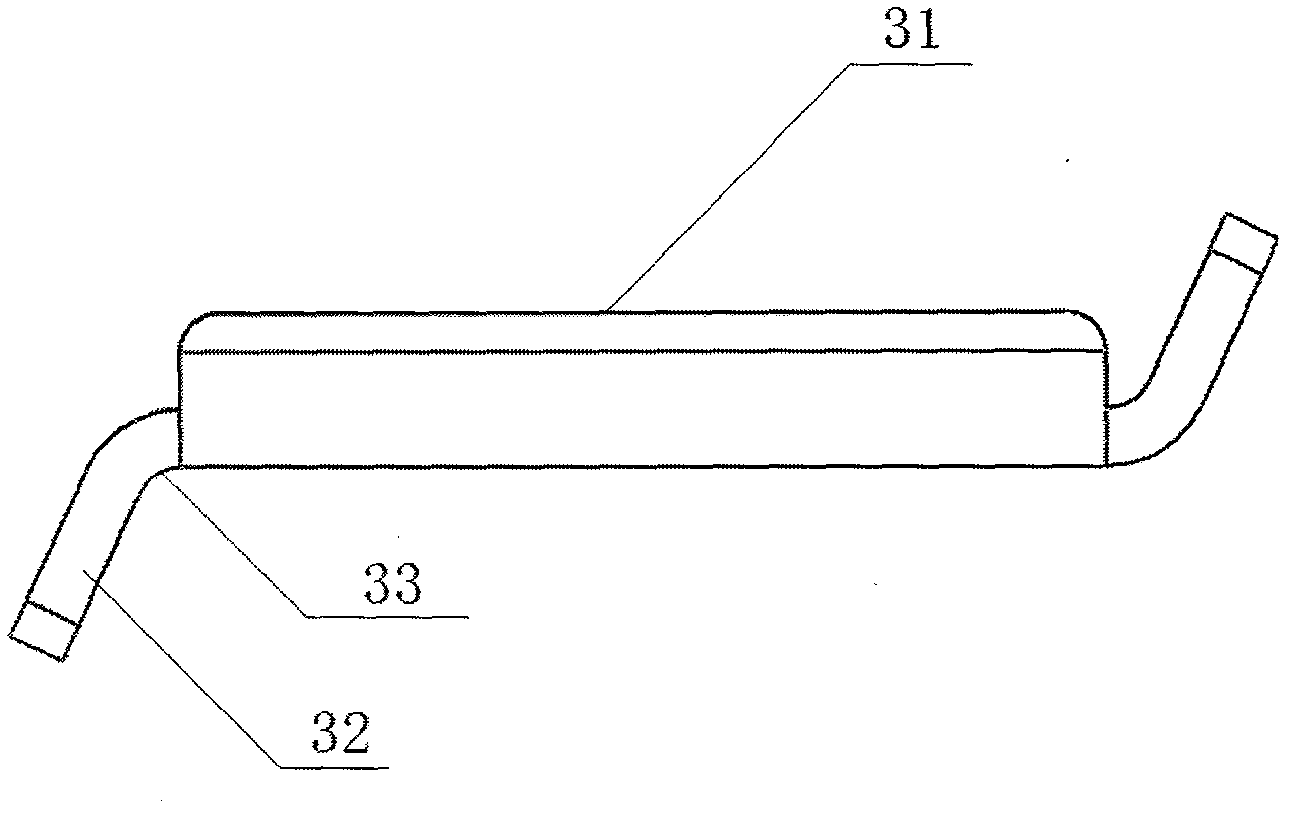

[0025] exist figure 1 The above shows the use of steel wire ropes to connect the buckles (3) to connect the staggered steel wire ropes in groups of two, so that the two staggered steel wire ropes form a steel wire rope with full tension, and do not rely on the insertion and removal of rubber. The resistance can provide the tension strength guarantee for the interface. Taking the old-fashioned three-stage lapped conveyor belt as an example, the density of the wire ropes at the interface is 33% higher than the original wire rope density of the conveyor belt. Finally, the number of wire ropes that can provide full tension accounts for 67% of the number of wire ropes with the original belt, which can fully meet the needs of operation under normal conditions (usually the safety factor of the conveying system design will not be lower than 140%), so the new type The steel wire rope arrangement method is combined with the steel wire rope connection lock, and the steel wire rope expose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com