Linear friction-current compound heat source welding method

A welding method and composite heat source technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as poor joint quality, achieve stable vibration output, good controllability, and achieve high thermal strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

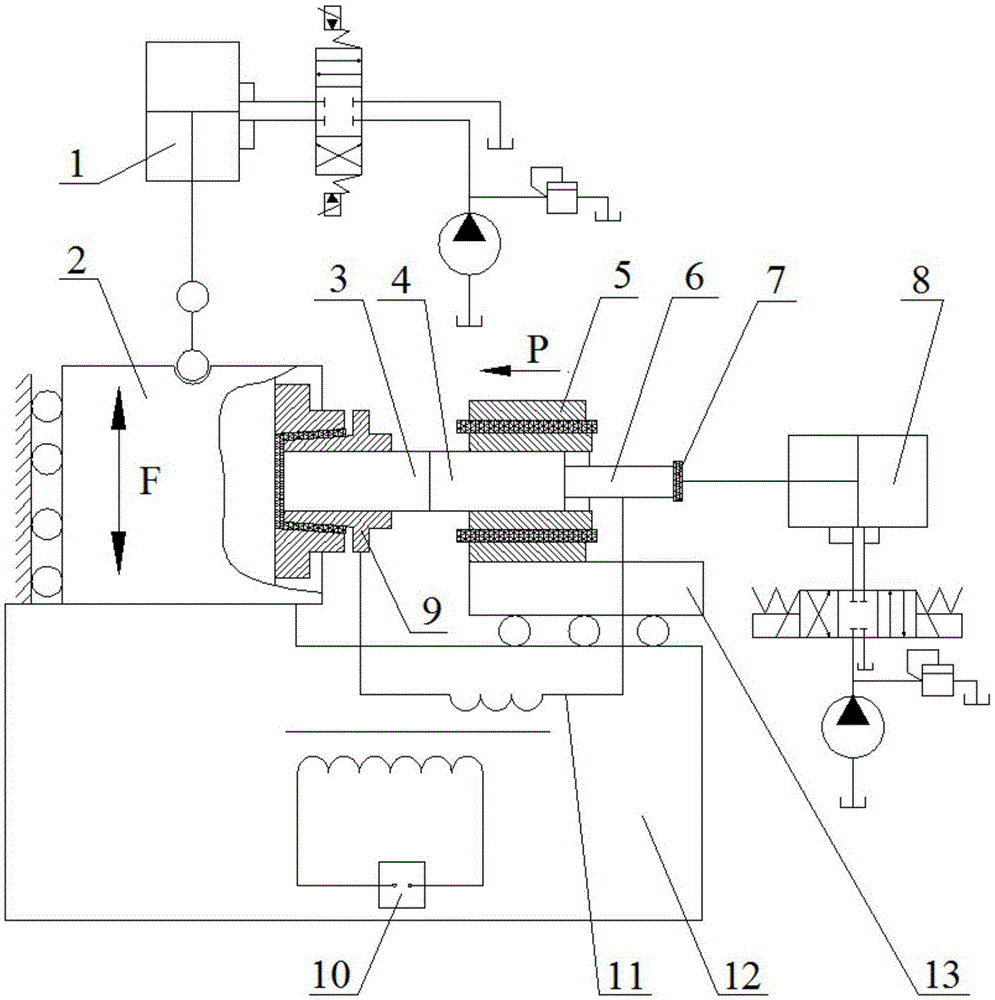

[0016] refer to figure 1 . The specific steps of the linear friction-current composite heat source welding method of the present invention are as follows:

[0017] Step 1, put the vibrating end workpiece 3 into the vibration fixture 9, set the insulating material 7 in the middle of the vibrating fixture 9 and the left end of the vibrating end workpiece 3, and cut off the current conduction between the vibrating end workpiece 3 and the bed 12 through the insulating material 7; The clamp 9 applies clamping pressure, thereby clamping the workpiece 3 at the vibrating end and insulating the workpiece 3 at the vibrating end from the bed 12;

[0018] Put the mobile end workpiece 4 into the movable fixture 5, set the insulating material 7 in the middle of the movable fixture 5 and the right end of the fixed ejector rod 6 connected with the movable end workpiece 4, and cut off the gap between the movable end workpiece 4 and the bed 12 through the insulating material 7 Current conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com