Manual intermediate frequency resistance welding control cabinet

A resistance welding and control cabinet technology, applied in welding power supply, welding power supply, etc., can solve problems such as low efficiency, high energy consumption, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

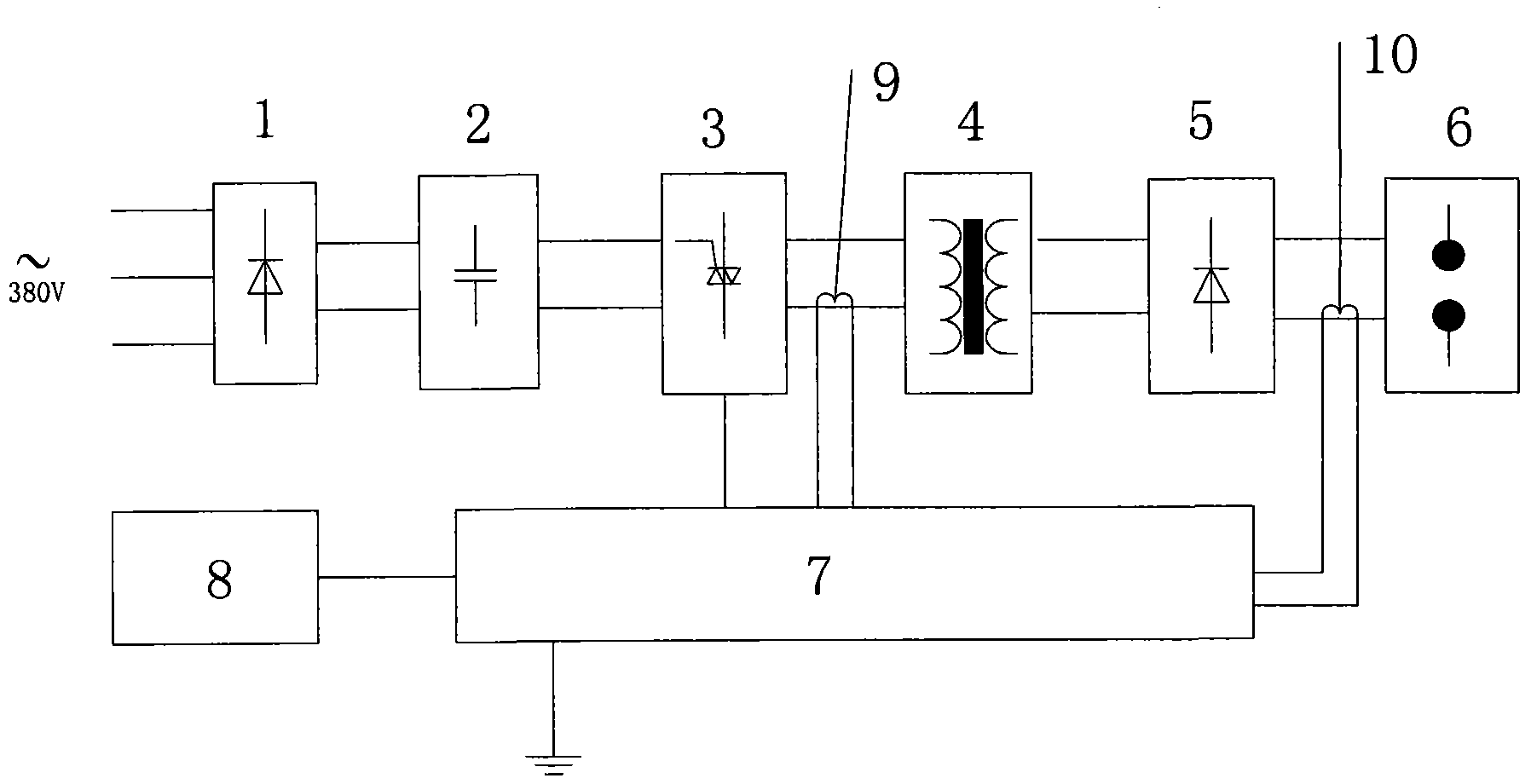

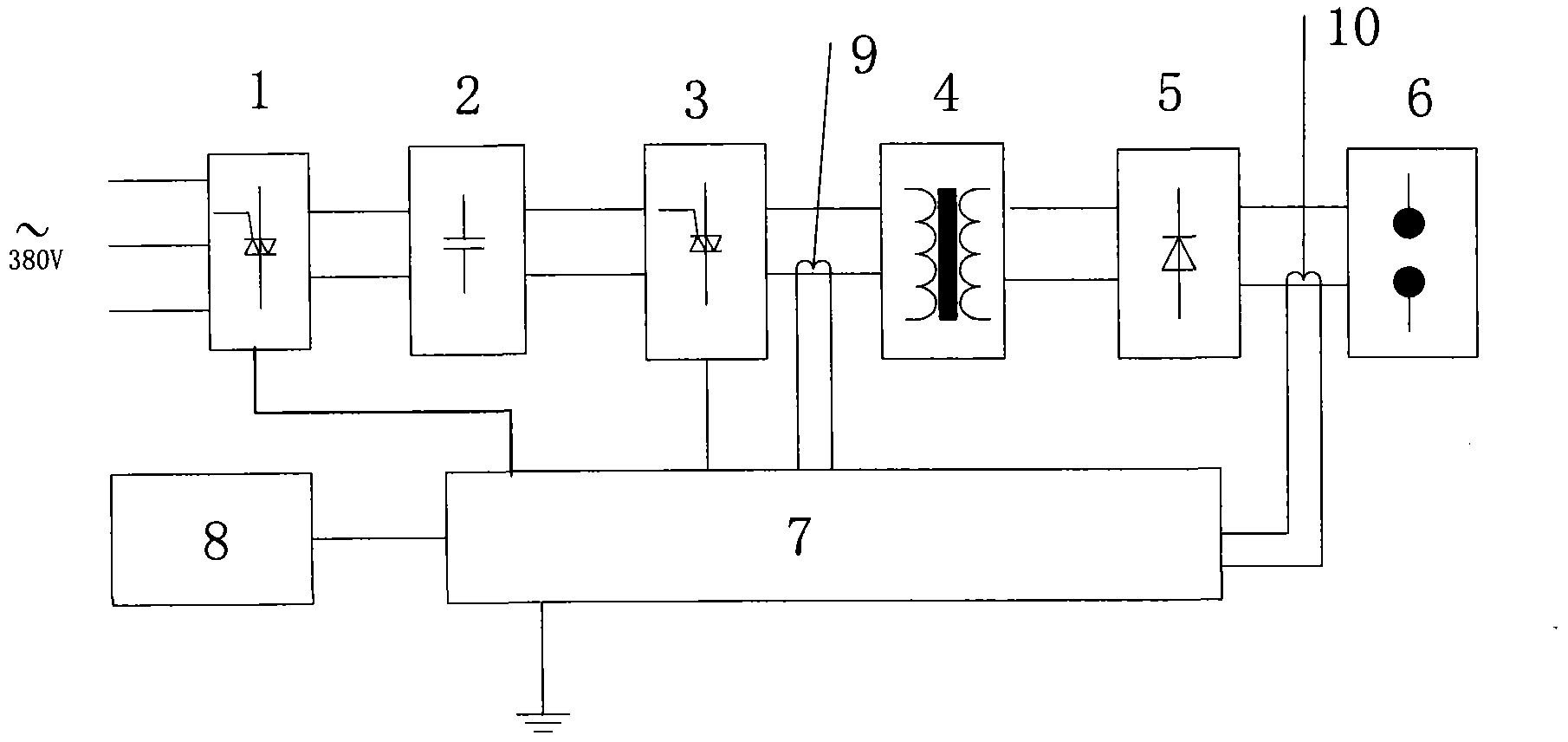

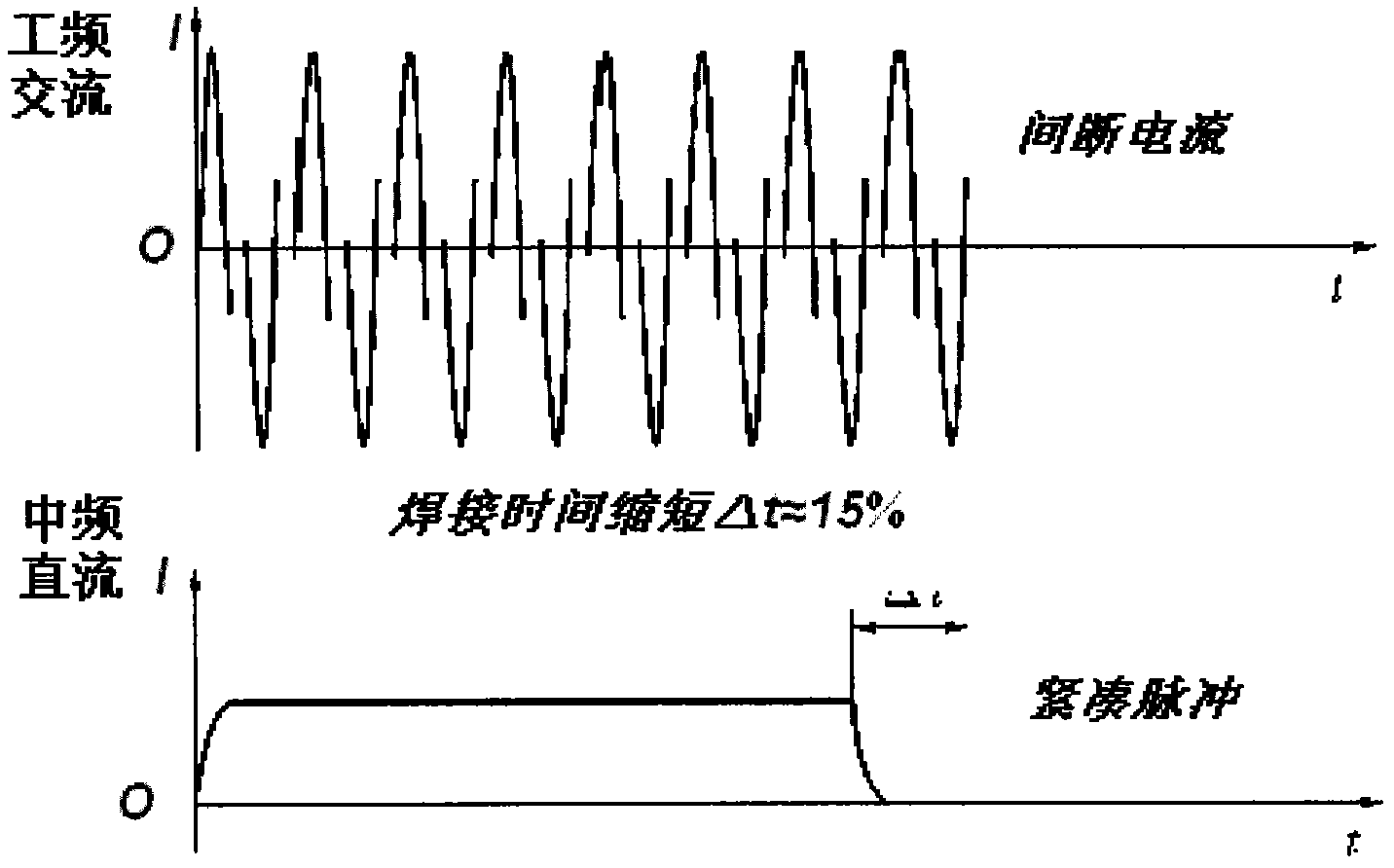

[0012] Such as figure 1 The circuit diagram of the first embodiment of the manual intermediate frequency resistance welding control cabinet shown includes a power circuit part and a control circuit part. The power circuit part includes a three-phase AC power supply, a three-phase full-bridge rectifier circuit 1, a filter circuit 2, an inverter Circuit 3, intermediate frequency transformer 4, unidirectional output protection circuit 5 and output electrode 6, the inverter circuit 3 is an IGBT inverter circuit, the output current frequency is 600-1000Hz, and the secondary coil of the intermediate frequency transformer 4 has a center tap as the current input terminal , the two ends of the secondary coil are current output terminals, the current output terminals are connected to the current input terminals through the one-way output protection circuit 5 and the output electrode 6, the control circuit part includes a central processing unit 7, a clock circuit 8 and a sensor circuit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com