A high-strength platinum material and preparation method for high-temperature deformation resistance

A high-temperature deformation, high-strength technology, used in transportation and packaging, metal processing equipment, etc., can solve the problems of deformation resistance, erosion resistance, corrosion resistance that cannot meet expected requirements, short service life, and easy creep deformation. Ensure homogenization, ensure ingredients, and achieve the effect of high application value

Active Publication Date: 2021-11-30

CHONGQING MATERIALS RES INST

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the advancement of industry, the requirements for materials are becoming more and more stringent. The platinum materials prepared by the existing technology cannot meet the expected requirements in terms of deformation resistance, erosion resistance and corrosion resistance in specific environments at high temperatures above 1400°C. Components made of these materials are prone to creep deformation under high temperature conditions and have a short service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0035] Platinum: 997.5g (99.75% by weight), zirconia: 2g (0.2% by weight), yttrium oxide: 0.5g (0.05% by weight).

Embodiment 2

[0037] Platinum: 998.6g (99.86% by weight), zirconia: 0.7g (0.07% by weight), yttrium oxide: 0.5g (0.05% by weight), titanium carbide: 0.2g (0.02% by weight).

Embodiment 3

[0039] Platinum: 998g (99.8% by weight), zirconia: 1.5g (0.15% by weight). Titanium carbide: 0.5g (0.05% by weight).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

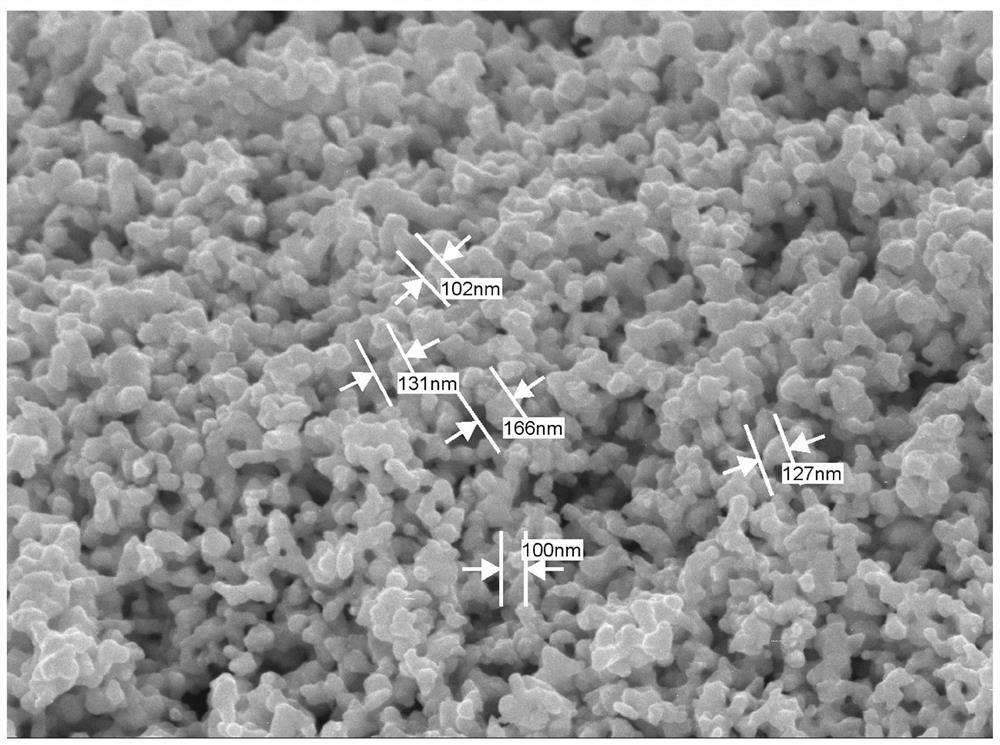

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a high-strength platinum material used to resist high-temperature deformation and a preparation method. The material is composed of platinum and a strengthening phase, and the strengthening phase is any one of zirconia, yttrium oxide, and titanium carbide particles dispersed in platinum. One and several kinds, the weight percent content of each component of the material is the strengthening phase component>0~≤0.4wt%, platinum is the balance. The material has high strength and excellent deformation resistance, erosion resistance, corrosion resistance and high temperature creep resistance performance under high temperature conditions above 1400 °C in specific environments. Components made of this material have good resistance to high temperature deformation and long service life , can effectively reduce the production cost of the application field.

Description

technical field [0001] The invention belongs to the field of metal materials, in particular to a high-strength platinum material used to resist high-temperature deformation and a preparation method. Background technique [0002] Metal materials that can withstand high temperatures (above 1400°C) and resist deformation are widely used in the industrial field. Platinum material is widely used because of its high melting point, oxidation resistance, corrosion resistance and other excellent properties. Therefore, platinum material is a very advantageous high-temperature metal material, but its high-temperature mechanical properties are poor. In the prior art, the high-temperature mechanical properties of the platinum matrix have been improved to a certain extent by means of solid solution strengthening and internal oxidation strengthening of the second phase particles. The high temperature mechanical properties of the material are not improved enough. With the advancement of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C5/04C22C1/05C22C1/10B22F9/16B22F3/02B22F3/10B22F3/17B22F3/18B22F1/00

CPCC22C5/04C22C1/051B22F9/16B22F3/02B22F3/10B22F3/17B22F3/18B22F2009/165B22F1/05

Inventor 唐会毅吴保安罗维凡罗凤兰李凤肖雨辰万伟建

Owner CHONGQING MATERIALS RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com