Method for preparing compact W-Cu composite material at low temperature

A composite material, dense technology, applied in the field of low-temperature preparation of dense W-Cu composite materials, to achieve the effect of precise control of composition, high degree of consistency, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

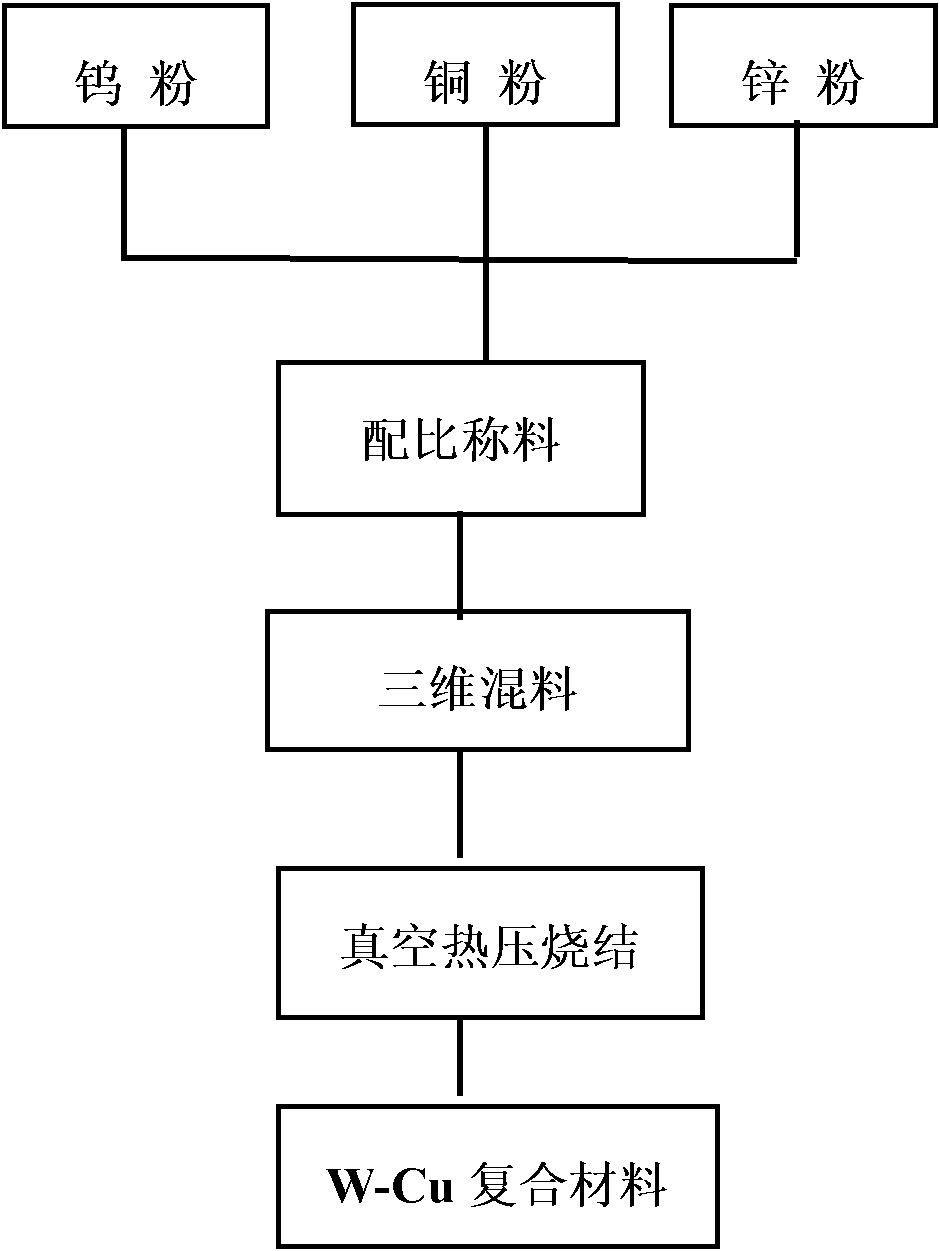

Method used

Image

Examples

Embodiment 1

[0024] The volume ratio of W powder and Cu powder is according to W: Cu=10:90%, and Zn is added to account for 0.5% of the total mass fraction of W-Cu, and the particle size of W is 5 μm, and the particle size of Cu is 20 μm. Then put it into a vacuum hot pressing furnace, and carry out vacuum hot pressing sintering according to the specified vacuum hot pressing sintering process. The sintering process is 700°C-200MPa-4h. Previously, the heating rate was 10°C / min, 600°C~650°C heating rate was 5°C / min, 650°C~700°C heating rate was 2°C / min, kept at 700°C for 4 hours, and cooled naturally to obtain a dense W-Cu composite Material.

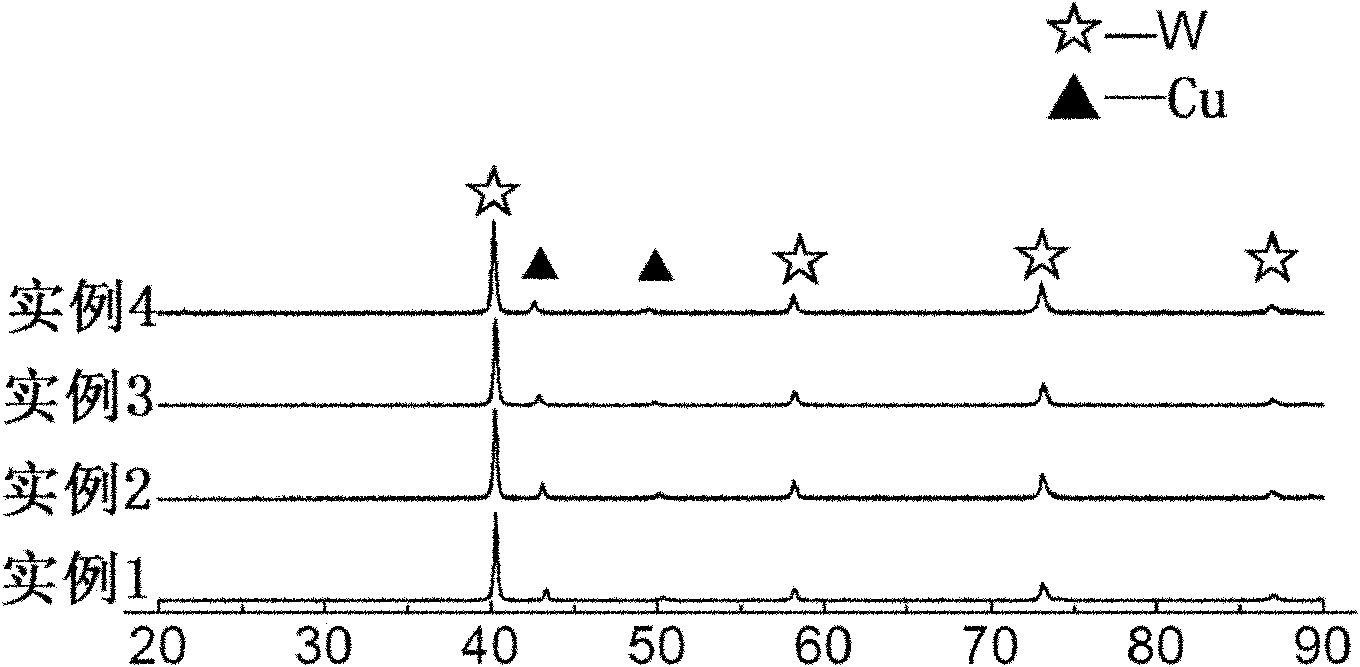

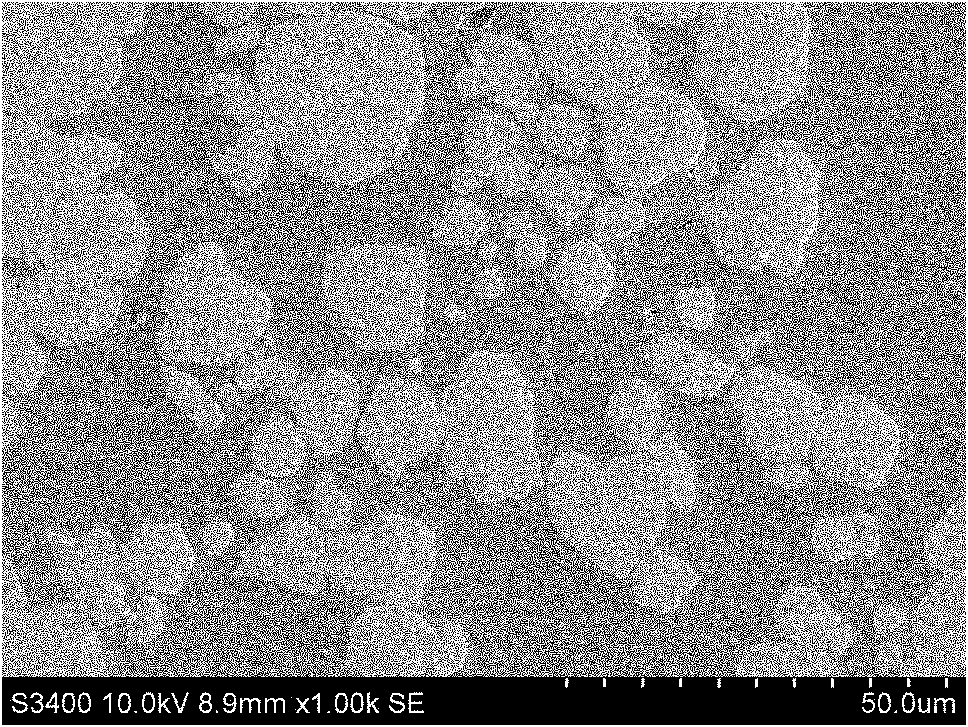

[0025] The measured density of the W-Cu composite material is 9.63g / cm 3 , the density reaches 97.5%. The phase analysis results of the composite material are as follows: figure 2 As shown, it can be seen from the figure that there are only two phases of W and Cu in the main phase; the microstructure is as follows image 3 As shown, the W-Cu comp...

Embodiment 2

[0027] The volume ratio of W powder and Cu powder is W:Cu=75:25%, and Zn is added to account for 2.0% of the total mass fraction of W-Cu. Then put it into a vacuum hot pressing furnace, and carry out vacuum hot pressing sintering according to the specified vacuum hot pressing sintering process. The sintering process is 900°C-80MPa-1h. Previously, the heating rate was 10°C / min, the heating rate was 5°C / min at 800°C~850°C, and the heating rate was 2°C / min at 850°C~900°C, kept at 900°C for 1 hour, and cooled naturally to obtain a dense W-Cu composite Material.

[0028] The measured density of the W-Cu composite material is 15.94g / cm 3 , the density reaches 97.8%. The phase analysis results of the composite material are as follows: figure 2 As shown, it can be seen from the figure that there are only two phases of W and Cu in the main phase; the microstructure is as follows Figure 4 As shown, the W-Cu composite material is compact as a whole, and W and Cu are evenly distribu...

Embodiment 3

[0030] The volume ratio of W powder and Cu powder is according to W:Cu=60:40vol%, and Zn is added to account for 2.0% of the total mass fraction of W-Cu. Then put it into a vacuum hot pressing furnace, and carry out vacuum hot pressing sintering according to the specified vacuum hot pressing sintering process. The sintering process is 850°C-80MPa-3h. Previously, the heating rate was 10°C / min, 750°C~800°C heating rate was 5°C / min, 850°C~850°C heating rate was 2°C / min, kept at 850°C for 3 hours, and cooled naturally to obtain a dense W-Cu composite Material.

[0031] The measured density of the W-Cu composite material is 14.45g / cm 3 , the density reaches 97.39%. The phase analysis results of the composite material are as follows: figure 2 shown, from figure 2 It can be seen that the main phase is only W and Cu two phases; the microstructure is as follows Figure 5 As shown, the W-Cu composite material is compact as a whole, and W and Cu are evenly distributed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com