Preparation method for nano-cobalt/graphene core-shell structured electrocatalyst

A technology of core-shell structure and electrocatalyst, which is applied in the direction of nanotechnology, nanotechnology, structural parts, etc., can solve the problems of high cost of noble metal catalysts, complicated preparation process, and many influencing factors, so as to increase the number of catalytic active sites and improve the preparation process. Simple, precise ingredient control for results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

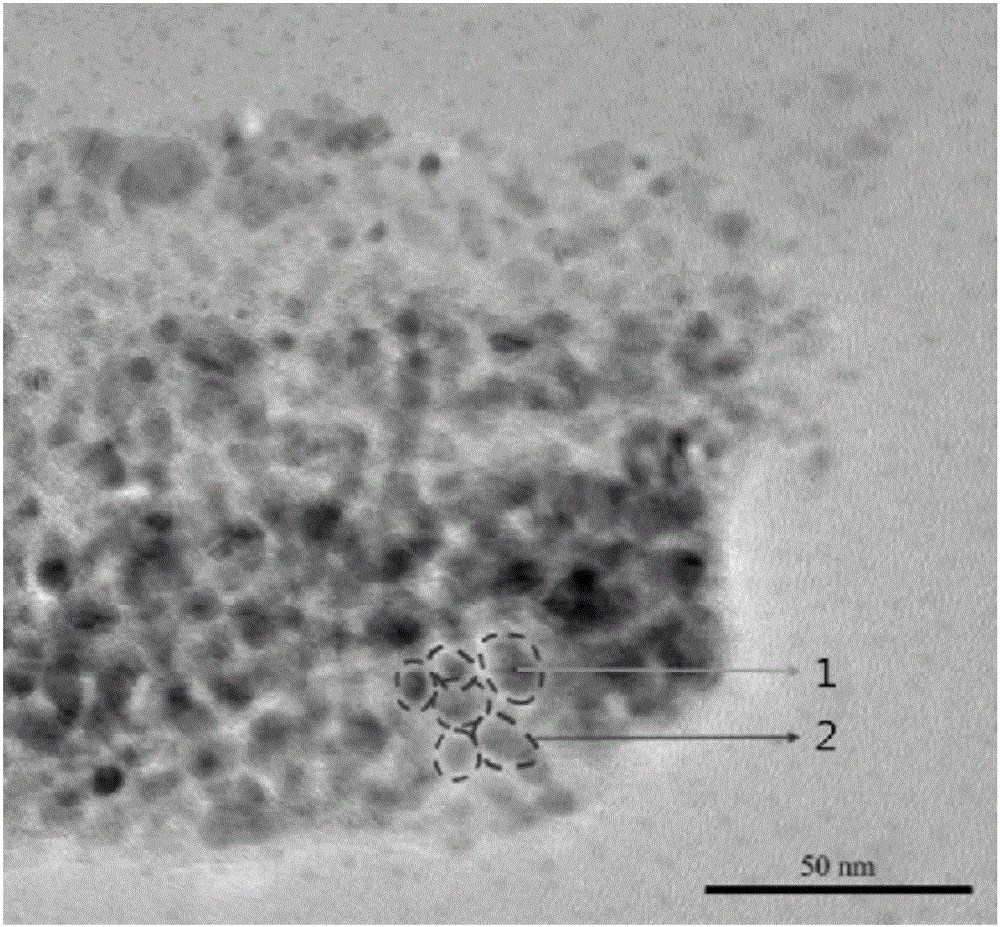

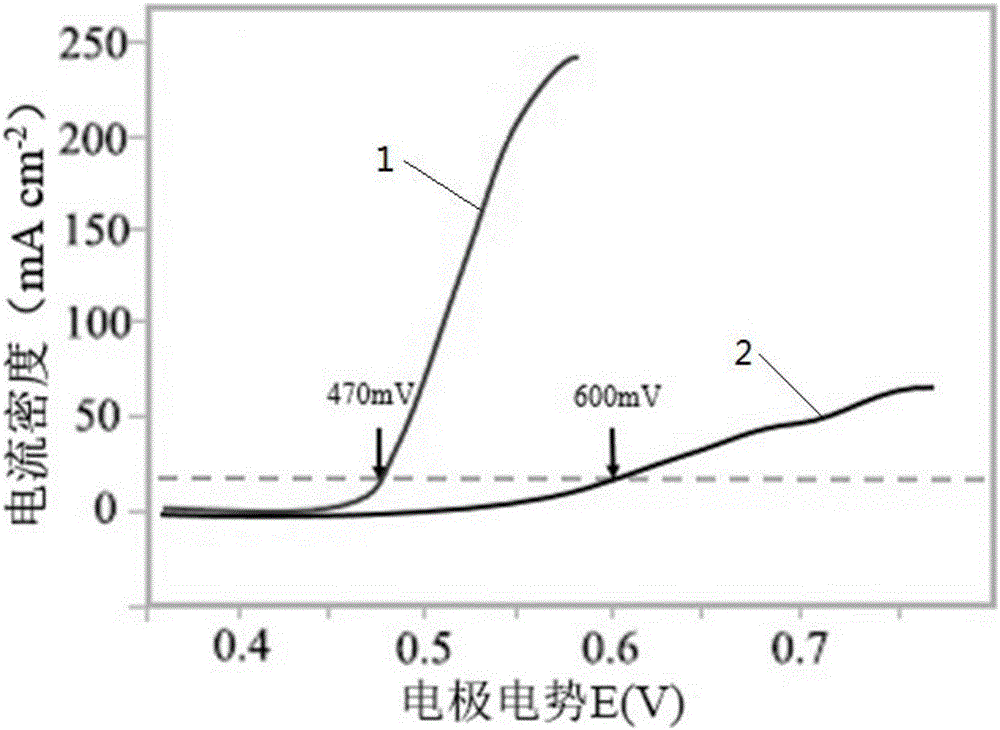

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: the preparation method of a kind of nano-cobalt / graphene core-shell structure electrocatalyst described in this embodiment is carried out according to the following steps:

[0024] 1. Ultrasonically clean the foamed nickel with concentrated hydrochloric acid with a weight percentage of 36% to 38% for 1min to 5min to obtain the foamed nickel with the NiO layer removed from the surface, and then ultrasonically clean the foamed nickel with absolute ethanol for 1min to 5min , and finally cleaned with deionized water to obtain a foamed nickel substrate;

[0025] 2. Add cobalt nitrate hexahydrate, ammonium fluoride and urea into deionized water to obtain a deep red clear solution;

[0026] The mass ratio of described cobalt nitrate hexahydrate and ammonium fluoride is 1:(0.2~5); the mass ratio of described cobalt nitrate hexahydrate and urea is 1:(0.2~5); The volume ratio of cobalt mass to deionized water is 1g:(20~100)mL;

[0027] 3. Put the foamed...

specific Embodiment approach 2

[0036] Specific embodiment two: this embodiment is different from specific embodiment one: the mass ratio of cobalt nitrate hexahydrate described in step 2 and ammonium fluoride is 1:0.46; Cobalt nitrate hexahydrate described in step 2 and The mass ratio of urea is 1:0.92; the volume ratio of the mass of cobalt nitrate hexahydrate described in step 2 to deionized water is 1g:55.17mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step three, the polytetrafluoroethylene reactor is then placed in a heating furnace to be heated to a temperature of 180°C, and the temperature is 180°C Under certain conditions, keep warm for 6h ~ 12h. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com