Composite flexible pipe anti-compression armor layer

A technology of composite hose and armor layer, which is applied in the field of hose, can solve the problems of increased creep of the inner layer and loss of cross-section interlocking function, and achieve the effect of reducing weight and increasing bending flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

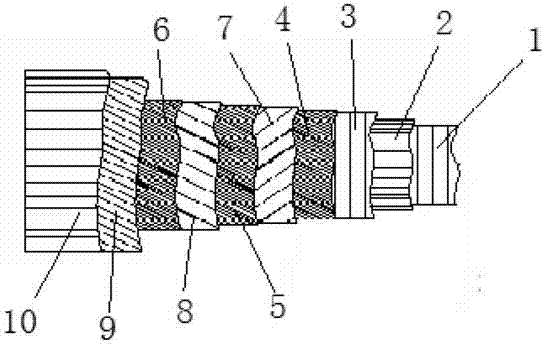

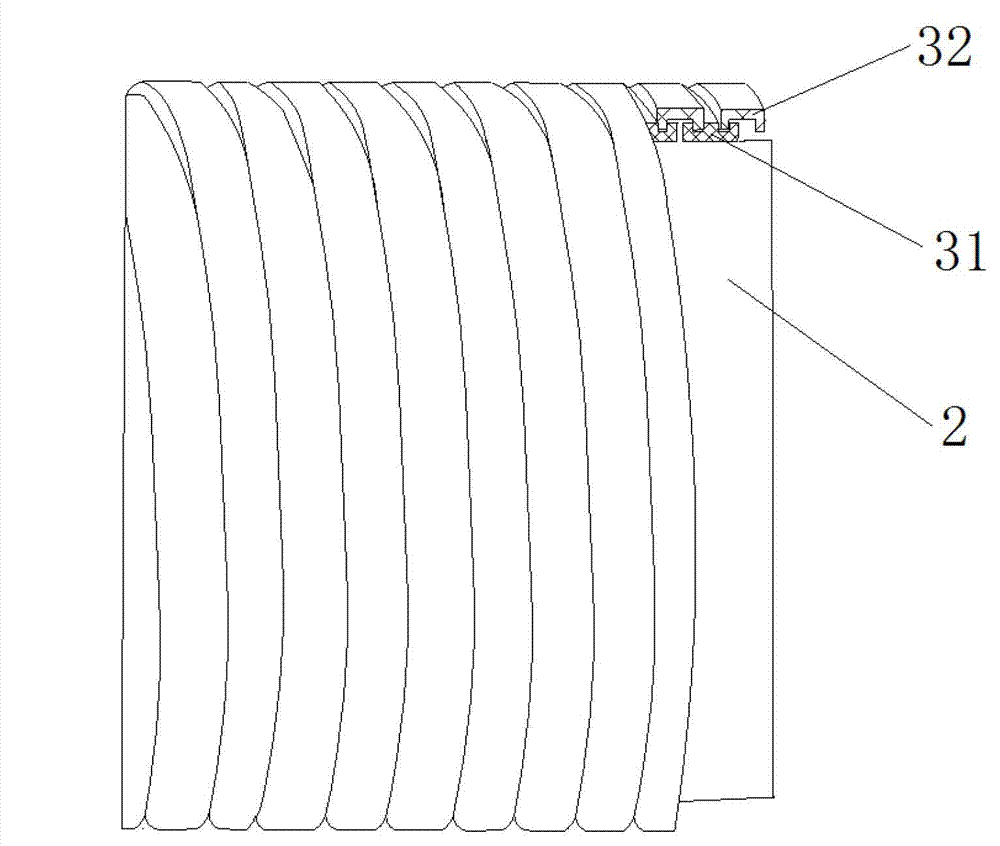

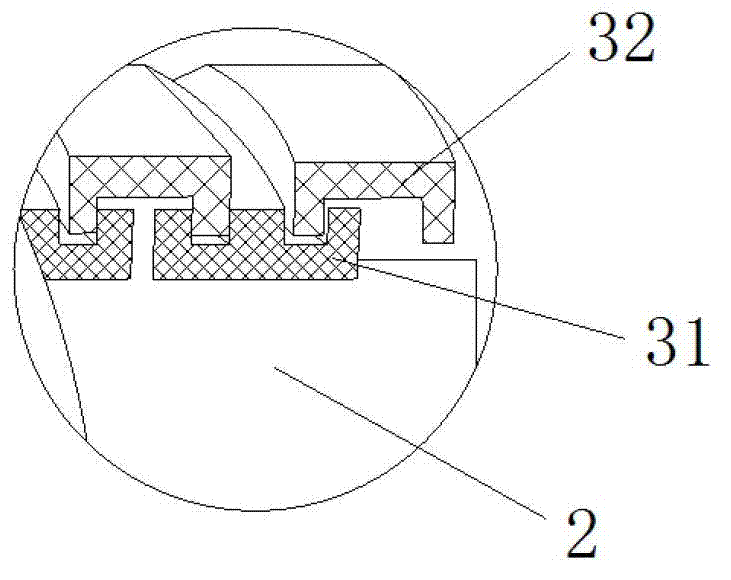

[0013] Such as figure 1 As shown, the present invention is similar to the existing non-bonded composite hose, which includes a skeleton layer 1 wound by interlocking steel strips, and an inner lining layer for sealing and conveying fluid is arranged on the outer surface of the skeleton layer 1 2. A compression-resistant armor layer 3 is provided on the outer wall of the inner lining layer 2, and three layers of wear-resistant layers 4, 5, and 6 are wrapped on the outer surface of the compression-resistant armor layer 3 at intervals, and each wear-resistant layer 4, 5, and 6 Two layers of tensile armor layers 7 and 8 are arranged alternately between them, an insulation layer 9 is wrapped on the outer surface of the wear-resistant layer 6, and an outer coating layer 10 is wrapped on the outer surface of the insulation layer 9 to form a non-adhesive comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com