Automatic compound machine of composite shock-absorbing silencing piece

The technology of a laminating machine and a sound-absorbing sheet, which is applied in the field of laminating machines, can solve the problems of difficulty in realizing industrialized continuous production, insufficient bonding of metal plates, low production efficiency, etc., and achieves maintenance of performance, significant shock resistance and noise reduction, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

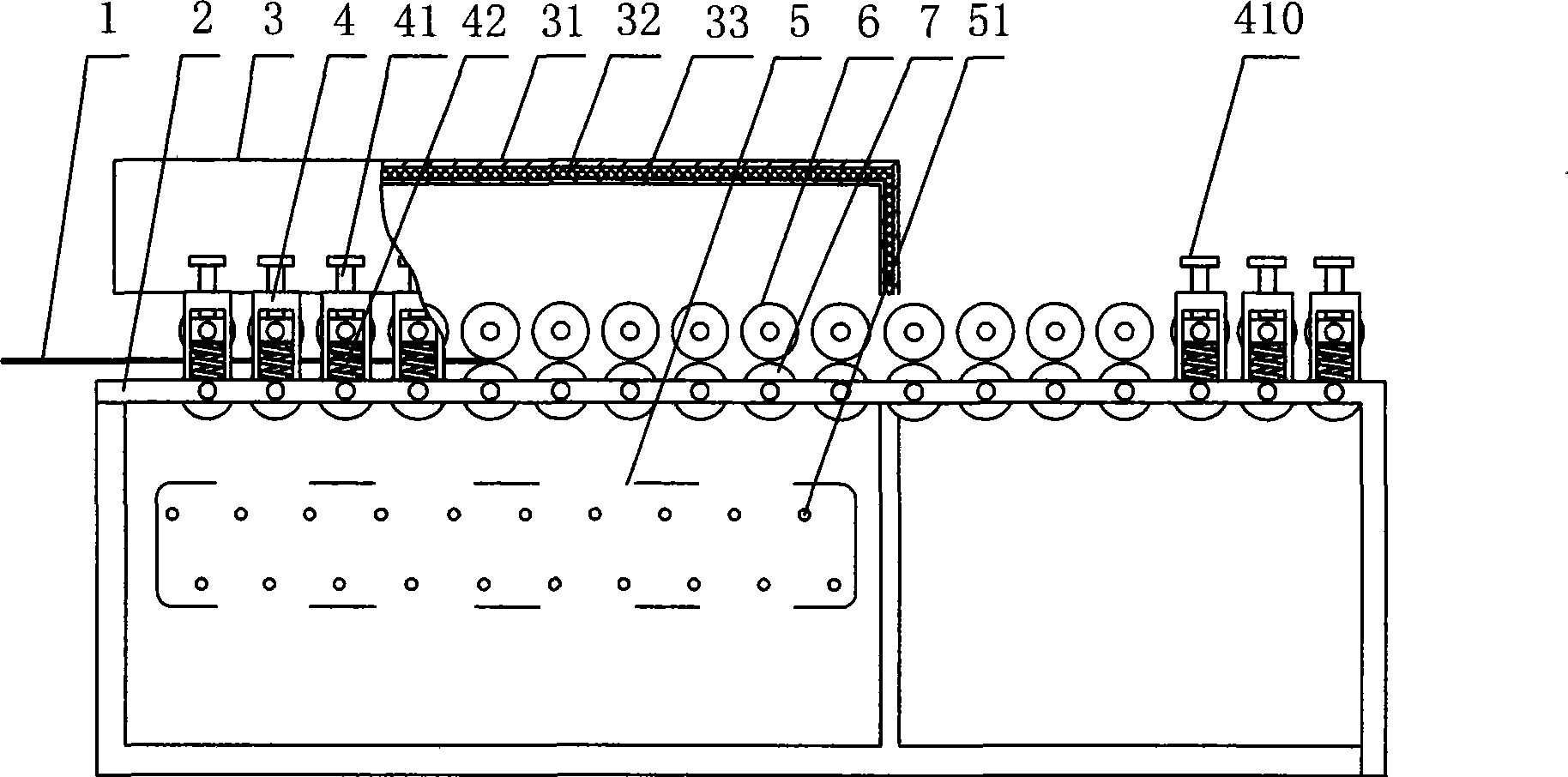

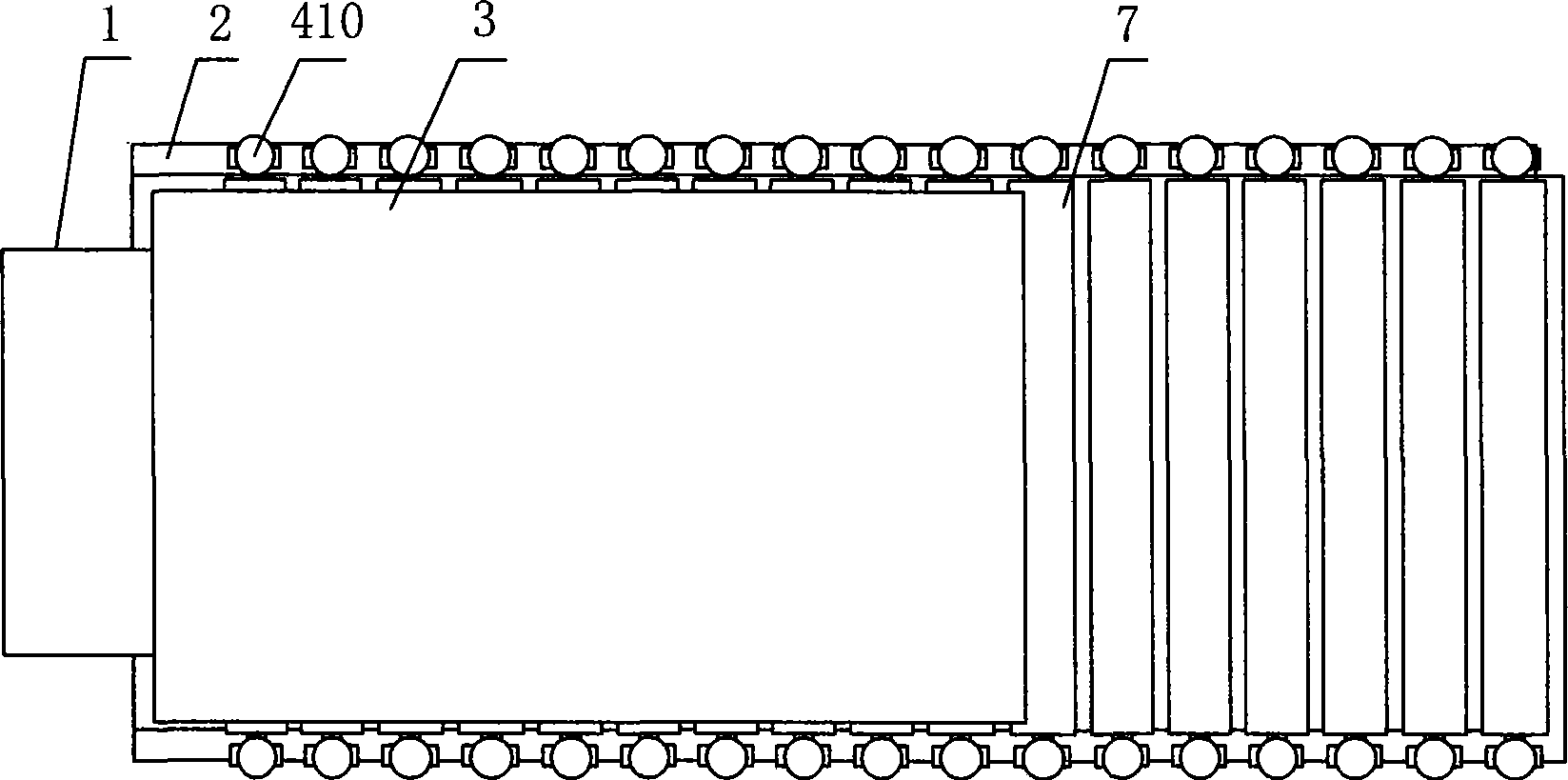

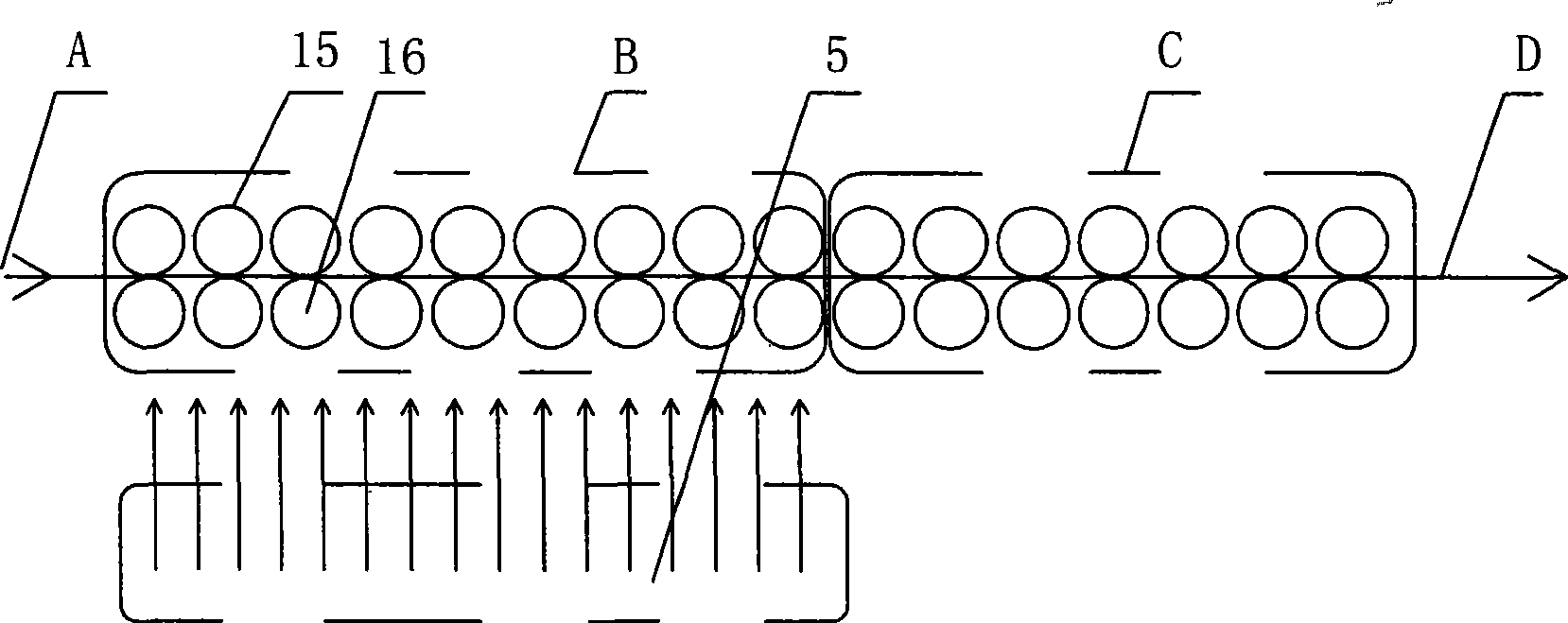

[0020] Example 1: figure 1 It is a structural schematic diagram of a preferred embodiment of the present invention; figure 2 is its top view. Depend on figure 1 and combine figure 2 It can be seen that the machine is mainly composed of a frame 2, a heating device 5, a pressure roller 7, a pressure roller 6 and the like.

[0021] The pressure roller 7 is arranged on the horizontal plane of the frame 2, and the pressure roller 6 which is close to the pressure roller 7 and forms a counter-rotating relationship with it is arranged directly above the pressure roller 7. A pressure adjustment device 4 is provided between the backing roller 7 and the pressure roller 6. The pressure adjustment device 4 can adopt a common bolt compression spring structure, which includes an adjustment bolt 41 and a compression spring 42, wherein the end of the adjustment bolt 41 Set on the bearing seat of the pressure roller 6, the pressure spring 42 is arranged between the bearing seat of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com