Thermoplastic electrostatic flocking fabric as well as preparation method and application thereof

An electrostatic flocking and thermoplastic technology, applied in the direction of textiles and papermaking, grafted polymer adhesives, adhesive types, etc., can solve the problems of poor thermoplasticity, achieve low curing temperature, improve yield deformation, and uniform plastic deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

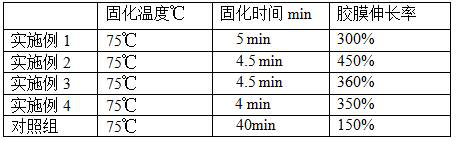

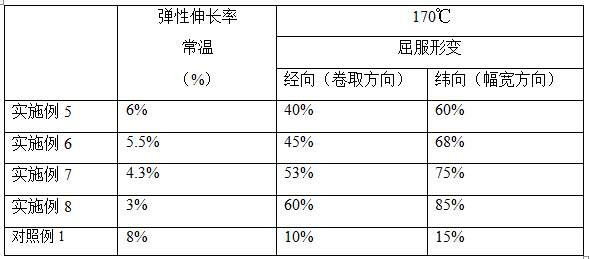

Examples

Embodiment 1

[0031] (1) Add 9g of OP-10 and 252ml of deionized water into a four-necked bottle equipped with a stirrer, a reflux condenser, a rubber stopper and a thermometer, and stir at a stirring speed of 1800r / min. After stirring for 15 minutes, drop into the mixing 300g of monomer (45g of methyl methacrylate, 30g of dibutyl maleate, 120g of butyl acrylate, 45g of ethyl acrylate, 60g of epoxy resin), and then continue to stir at 2000r / min until the mixture is uniform to obtain a pre-emulsion ;

[0032] (2) Dissolve 1.35g of initiator in 35ml of deionized water to obtain an initiator solution, dissolve 4g of cross-linking agent N-methylolacrylamide in 10ml of deionized water to obtain a cross-linking agent solution, and dissolve the Separate 2 / 3 of the prepared pre-emulsion for later use, add 20ml of initiator solution to the remaining 1 / 3 of the pre-emulsion in step (1), heat up while stirring, the stirring speed is 150r / min, and react at 45°C for 1h. Then when the temperature was slo...

Embodiment 2

[0034] (1) Add 1.2g of OP-10 and 298ml of deionized water into a four-necked bottle equipped with a stirrer, reflux condenser, rubber stopper and thermometer, and stir at a stirring speed of 1800r / min. After stirring for 15min, drop into Mix 345g of monomers (52g of methyl methacrylate, 35g of dibutyl maleate, 139g of butyl acrylate, 50g of ethyl acrylate, and 69g of epoxy resin), and then continue to stir at a speed of 2000r / min until the mixture is uniform, and the pre-mixture is obtained. Lotion;

[0035] (2) Dissolve 1.55g of initiator in 35ml of deionized water to obtain an initiator solution, dissolve 5g of cross-linking agent N-methylolacrylamide in 10ml of deionized water to obtain a cross-linking agent solution, and dissolve the Separate 2 / 3 of the prepared pre-emulsion for later use, add 20ml of initiator solution to the remaining 1 / 3 of the pre-emulsion in step (1), heat up while stirring at a stirring speed of 150r / min, react at 45°C for 1h, and then When the temper...

Embodiment 3

[0037] (1) Add 0.72g of OP-10 and 172ml of deionized water into a four-necked bottle equipped with a stirrer, reflux condenser, rubber stopper and thermometer, and stir at a stirring speed of 1800r / min. After stirring for 15min, drop into Mix 180g of monomers (18g of methyl methacrylate, 27g of dibutyl maleate, 61g of butyl acrylate, 36g of ethyl acrylate, and 38g of epoxy resin), and then continue to stir at a speed of 2000r / min until the mixture is uniform, and the pre-mixture is obtained. Lotion;

[0038] (2) Dissolve 0.72g of initiator in 35ml of deionized water to obtain an initiator solution, and dissolve 4g of cross-linking agent N-methylolacrylamide in 10ml of deionized water to obtain a cross-linking agent solution. Prepare in step (1) Separate 2 / 3 of the pre-emulsion for later use, add 20ml of initiator solution to the remaining 1 / 3 of the pre-emulsion in step (1), raise the temperature while stirring, the stirring speed is 150r / min, react at 45°C for 1h, and then ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com