Preparation method of composite coating on inner wall of reduction furnace bell jar

A composite coating, furnace clock technology, applied in the coating, superimposed layer plating, metal material coating process and other directions, can solve the problems of splicing plate welding seam and other problems, to prevent pollution, reduce costs, not easy to bulge and fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a composite coating on the inner wall of a reduction furnace bell, comprising the following steps:

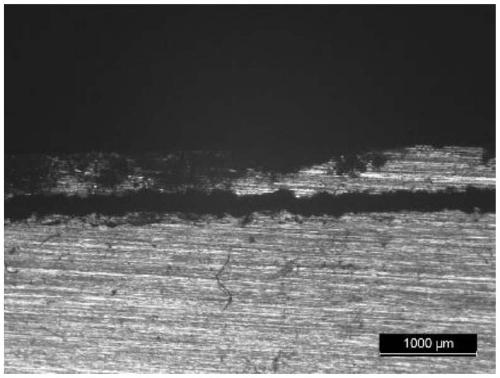

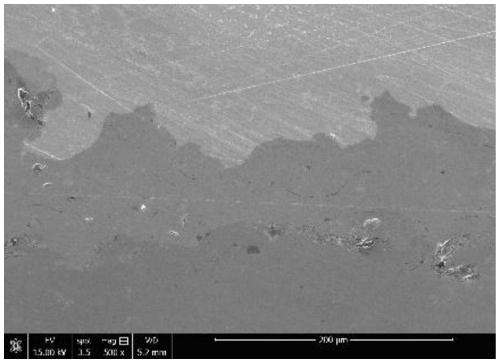

[0033] (1) Surface treatment: the inner wall of the reduction furnace bell jar is polished with 800# sandpaper, followed by acetone cleaning and compressed air drying of the inner wall of the reduction furnace bell jar to remove impurities such as grease on the inner wall of the bell jar;

[0034] (2) The inner diameter of the bell jar of the reduction furnace is 1.8m, and the matching protective fixture and spraying auxiliary equipment are installed to ensure that the bell jar of the reduction furnace is not damaged and polluted during the coating preparation process;

[0035] (3) Adopt supersonic flame spraying to prepare one deck transition layer on the stainless steel bell jar inner wall that has done surface treatment; Transition layer thickness is 100 μ m, porosity is less than 0.5%, bonding strength>50MPa; The raw material of described transi...

Embodiment 2

[0040] A method for preparing a composite coating on the inner wall of a reduction furnace bell, comprising the following steps:

[0041] (1) Surface treatment: the inner wall of the reduction furnace bell jar is polished with 800# sandpaper, followed by acetone cleaning and compressed air drying of the inner wall of the reduction furnace bell jar to remove impurities such as grease on the inner wall of the bell jar;

[0042] (2) The inner diameter of the reduction furnace bell is 1.8m, and the supporting protective fixture and spraying auxiliary equipment are installed to ensure that the reduction furnace bell will not be damaged and polluted during the coating preparation process; A transition layer is prepared on the inner wall of the treated stainless steel bell jar; the thickness of the transition layer is 50 μm, the porosity is less than 0.5%, and the bonding strength is > 50 MPa; the raw materials of the transition layer are aluminum, iron, copper, nickel, chromium, zinc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com