Monovalent selective cation exchange membrane as well as preparation method and application thereof

A cation exchange membrane, selective technology, applied in cation exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of difficult large-scale industrialization, poor long-term stability, high membrane resistance, and achieve the effect of resource extraction and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

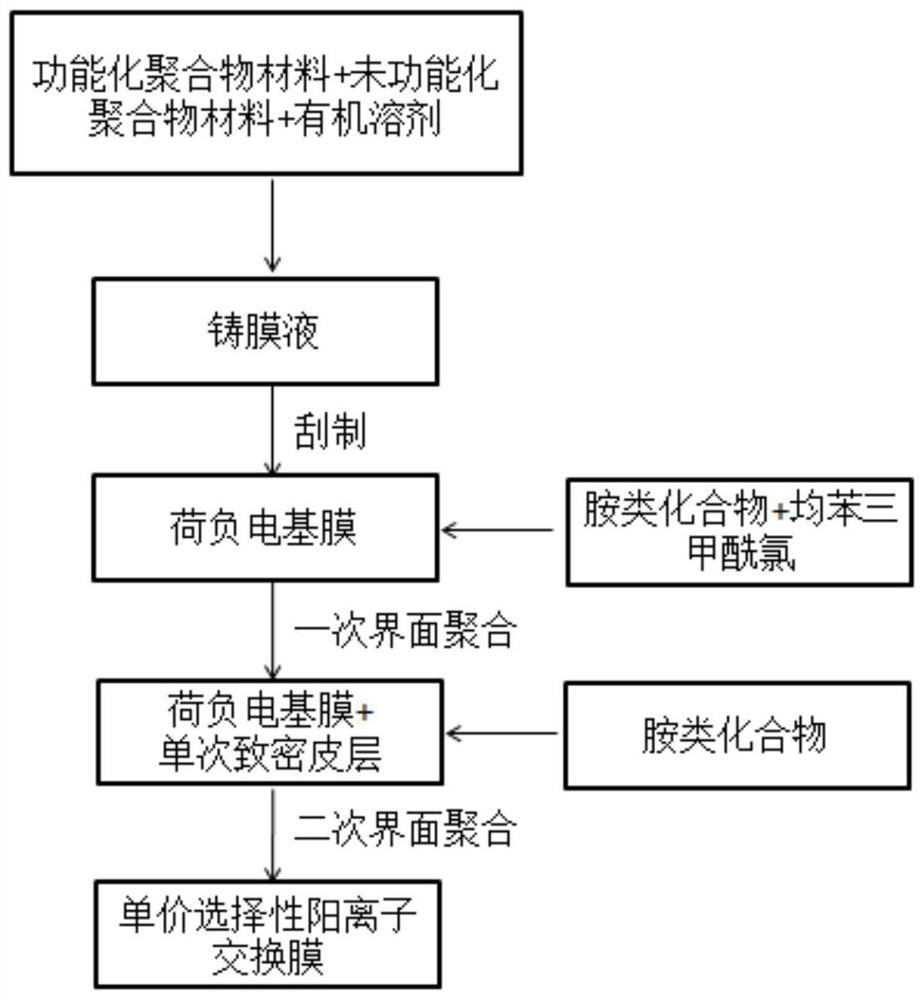

Method used

Image

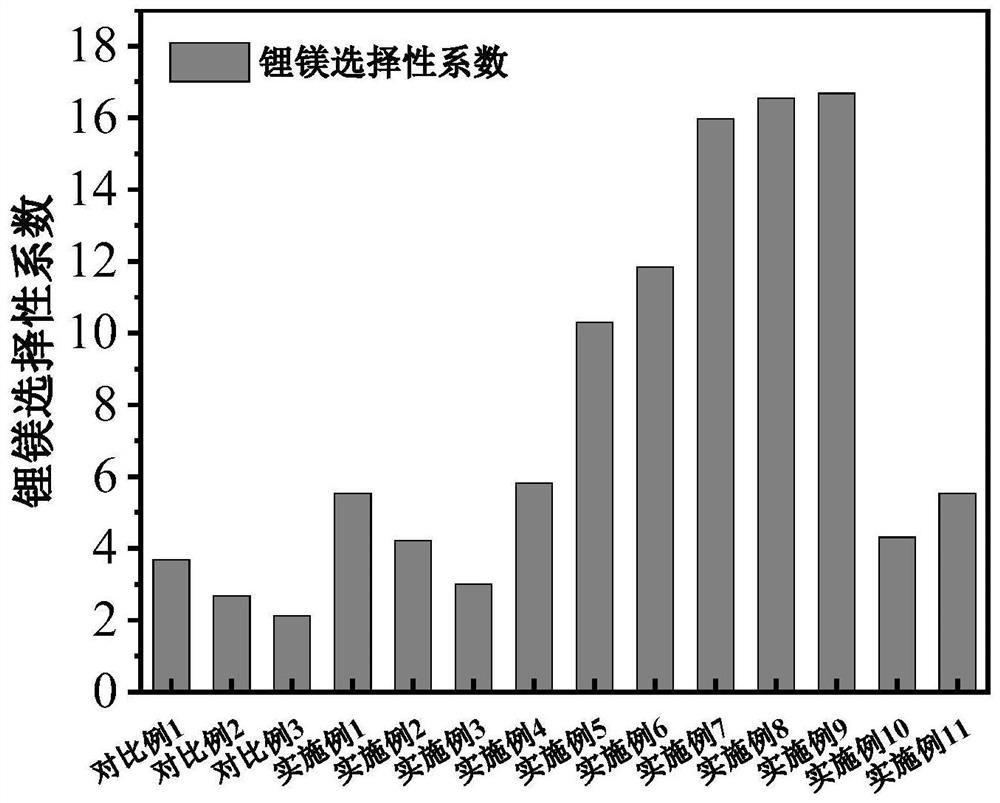

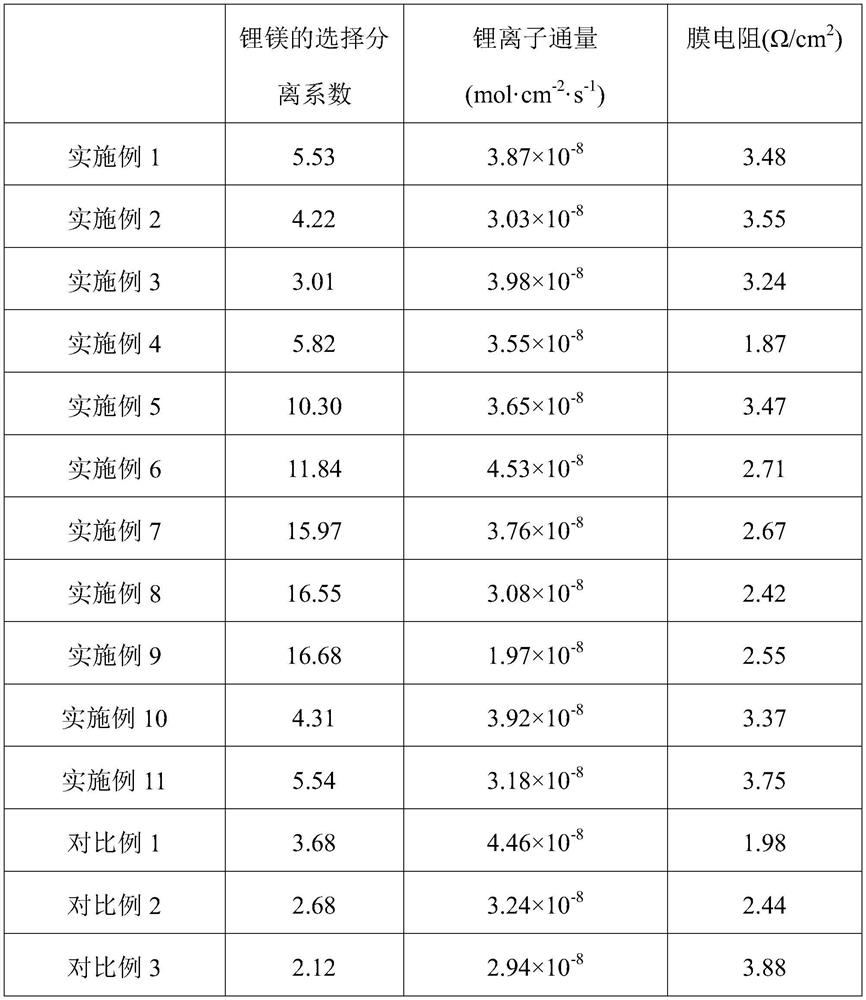

Examples

preparation example Construction

[0059] The preparation method of the sulfonated polymer material used in the following examples and comparative examples comprises the following steps:

[0060] 30g of polymer material and 80g of concentrated sulfuric acid were mechanically stirred in a constant temperature water bath at 80°C for 24h, the resulting mixed solution was added dropwise to ice water, then washed with deionized water until neutral, and vacuum-dried at 60°C to constant weight to obtain the degree of sulfonation It is 14% of sulfonated polymer material; the above description of the sulfonation method of polymer material is to more completely describe the technical solution of the present invention, and should not be regarded as a specific limitation of the present invention.

Embodiment 1

[0062] This embodiment provides a method for preparing a monovalent selective cation exchange membrane, and the preparation method includes the following steps:

[0063] (1) The sulfonated polyethersulfone and polyethersulfone with a mass ratio of 1:1 are mixed in nitrogen methyl pyrrolidone at a speed of 150 rpm and agitated at a temperature of 70 ° C until a transparent and uniform casting solution is formed, and then allowed to stand. After defoaming for 8 hours, the defoamed casting liquid was cast on a glass plate, scraped with a scraper with a thickness of 200 μm to form a film, volatilized for 5 s and then immersed in a water bath at 25 ° C. After the film fell off, the negatively charged base was obtained. membrane;

[0064] The sulfonation degree of the sulfonated polyethersulfone is 14%, and the nitrogen methylpyrrolidone accounts for 75wt% of the total mass of the casting liquid;

[0065] (2) Fix the negatively charged base film of step (1) in the PTFE frame, pour ...

Embodiment 2

[0072] This embodiment provides a method for preparing a monovalent selective cation exchange membrane, and the preparation method includes the following steps:

[0073] (1) The sulfonated polyethersulfone and polyethersulfone with a mass ratio of 0.3:1 are mixed in nitrogen methyl pyrrolidone at a speed of 150 rpm and agitated at a temperature of 70 ° C until a transparent and uniform casting solution is formed, and then allowed to stand. After defoaming for 7 hours, the defoamed casting liquid was cast on a glass plate, scraped with a scraper with a thickness of 200 μm to form a film, and immersed in a water bath at 25 °C after volatilization for 5 s. After the film fell off, the negatively charged base was obtained. membrane;

[0074] The sulfonation degree of the sulfonated polyethersulfone is 14%, and the nitrogen methylpyrrolidone accounts for 72wt% of the total mass of the casting solution;

[0075] (2) Fix the negatively charged base film described in step (1) on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com