A kind of molybdenum disulfide composite nano-gold photocatalyst and preparation method thereof

A molybdenum disulfide and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex catalyst preparation methods and low catalyst activity, and achieve improved photocatalytic activity and dispersion Good, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

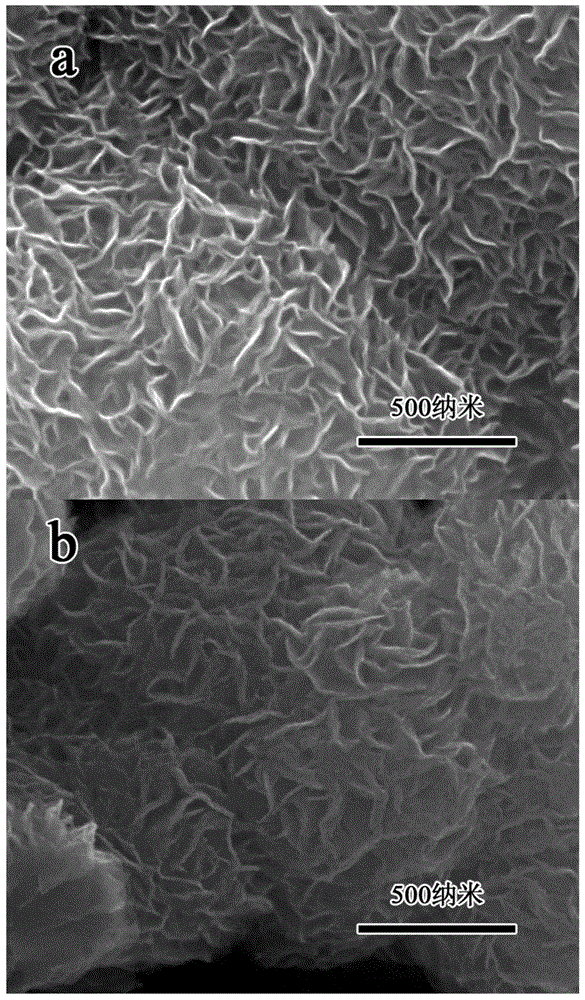

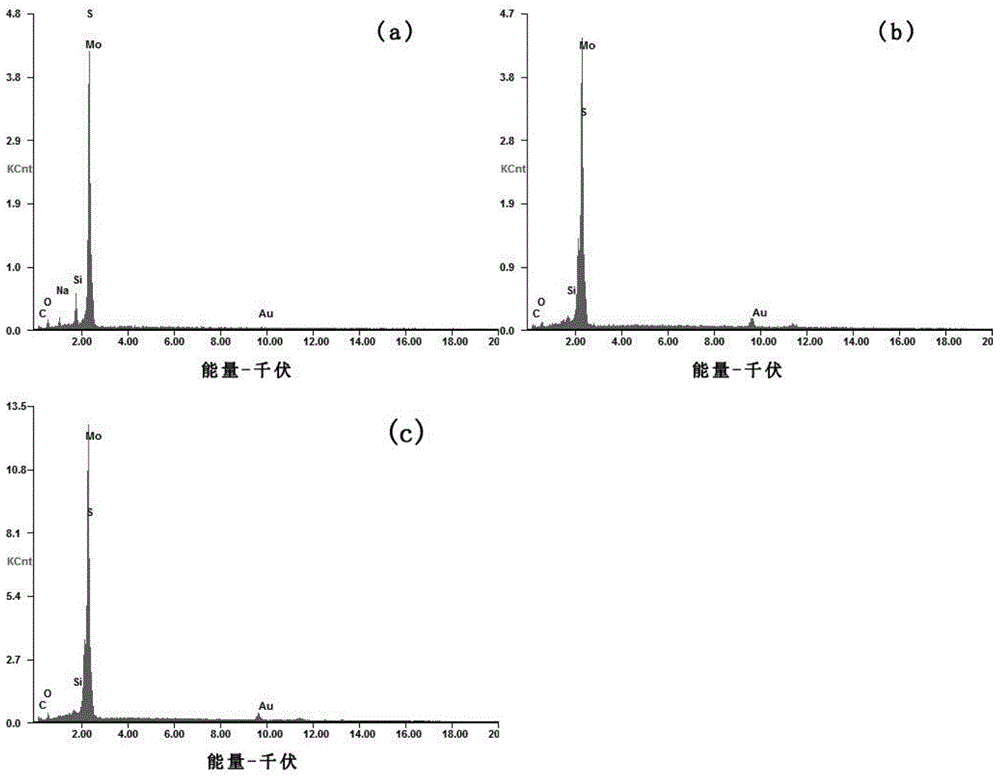

Image

Examples

Embodiment 1

[0022] A preparation method of molybdenum disulfide composite nano-gold photocatalyst, comprising the following steps:

[0023] Step 1: Prepare molybdenum disulfide nanoparticles by hydrothermal method: add 0.48g sodium molybdate and 0.76g thiourea to 40mL deionized water, stir and mix evenly, transfer the mixed solution to a 50mL polytetrafluoroethylene liner In an autoclave, keep the autoclave at 240°C for 24 hours; after cooling, filter to obtain a black solid, and wash it with deionized water for 5 times to obtain molybdenum disulfide nanoparticles;

[0024] Step 2: Add 0.04g of molybdenum disulfide nanoparticles prepared in step 1 into 20mL of deionized water, stir and mix evenly, then add 2mL of 0.024mol / L chloroauric acid solution and 4mL of 0.02mol / L citric acid dropwise Sodium solution, stirring continuously during the dropwise addition;

[0025] Step 3: irradiate the mixture obtained in step 2 under a 500W xenon lamp for 5 minutes, keep stirring continuously during ...

Embodiment 2

[0029] A preparation method of molybdenum disulfide composite nano-gold photocatalyst, comprising the following steps:

[0030] Step 1: Prepare molybdenum disulfide nanoparticles by hydrothermal method: add 0.48g sodium molybdate and 0.76g thiourea to 40mL deionized water, stir and mix evenly, transfer the mixed solution to a 50mL polytetrafluoroethylene liner In an autoclave, keep the autoclave at 240°C for 24 hours; after cooling, filter to obtain a black solid, wash it with deionized water for 5 times, and obtain molybdenum disulfide nanoparticles;

[0031] Step 2: Add 0.05g of molybdenum disulfide nanoparticles prepared in step 1 into 20mL of deionized water, stir and mix evenly, and then add 1mL of 0.024mol / L chloroauric acid solution and 3mL of 0.02mol / L vitamin C, stirring constantly during the dropping process;

[0032] Step 3: irradiate the mixed solution obtained in step 2 under a 400W xenon lamp for 8 minutes, keep stirring continuously during the irradiation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com