Zinc-plating material surface processing liquid with compound biological polysaccharide and preparation method thereof

A technology of surface treatment liquid and biological polysaccharide, applied in the direction of metal material coating process, etc., can solve the problems of reducing solution fluidity, high viscosity of chitosan solution, affecting passivation construction performance, etc., and achieves good passivation effect, passivation Excellent anti-corrosion effect and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

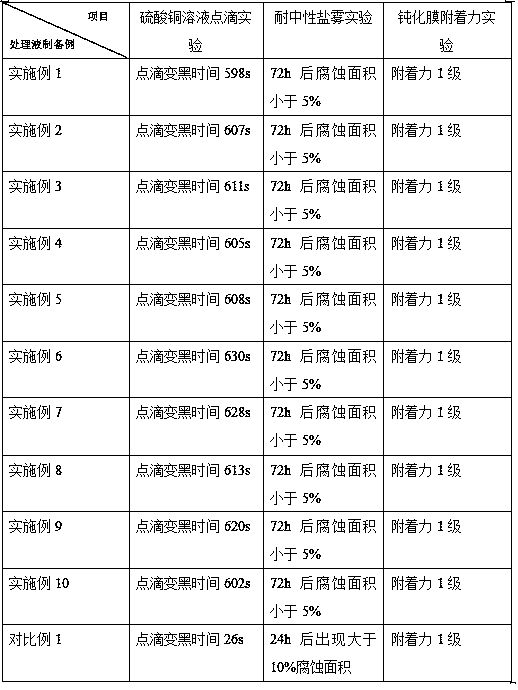

Examples

Embodiment 1

[0039] The prepared galvanized sheet surface treatment solution is calculated as 100g, and the specific dosage of each component is as follows:

[0040] Inulin 2.5g

[0041] Silane KH-560 8.0g

[0043] Nano silica sol 1.5g

[0044] pH adjuster is selected according to the adjustment end point

[0045] Yeast powder inulin volume 1 / 10~1 / 50

[0046] Deionized water 87.5g

[0047] The specific method of this embodiment is as follows:

[0048] In a 250ml beaker, add 87.5g deionized water and 2.5g inulin, stir to dissolve the inulin completely, add a small amount of yeast powder, stir and ferment for 3.5h at 35℃ water bath temperature, add 8.0g silane coupling agent at room temperature KH-560, add a few drops of 10% nitric acid to adjust the pH of the system to about 4, continue to stir for 2h, and finally add 0.5g zirconium nitrate and 1.5g nano silica sol, stir for 3h to get the composite inulin plating Zinc plate surface treatment liquid.

Embodiment 2

[0050] The prepared galvanized sheet surface treatment solution is calculated as 100g, and the specific dosage of each component is as follows:

[0051] Inulin 3.0g

[0052] Silane KH-560 6.0g

[0053] Silane KH-570 2.0g

[0055] Nano silica sol 1.2g

[0056] pH adjuster is selected according to the adjustment end point

[0057] Yeast powder inulin volume 1 / 10~1 / 50

[0058] Deionized water 87.0g

[0059] The specific method of this embodiment is as follows:

[0060] In a 250ml beaker, add 87.0g deionized water and 3.0g inulin, stir to dissolve the inulin completely, add a small amount of yeast powder, stir and ferment for 3.5h at 35℃ water bath temperature, add 6.0g silane coupling agent at room temperature KH-560 and 2.0g silane coupling agent KH-570, add a few drops of 10% nitric acid to adjust the pH of the system to about 4, continue to stir for 2.0h, and finally add 0.8g zirconium nitrate and 1.2g nano silica sol , Stir for 3h to get the surface treatme...

Embodiment 3

[0062] The prepared galvanized sheet surface treatment solution is calculated as 100g, and the specific dosage of each component is as follows:

[0063] Inulin 3.5g

[0064] Silane KH-570 8.0g

[0065] Zirconium nitrate 1.0g

[0066] Nano silica sol 1.0g

[0067] pH adjuster is selected according to the adjustment end point

[0068] Yeast powder, inulin volume 1 / 10~1 / 50

[0069] Deionized water 86.5g

[0070] The specific method of this embodiment is as follows:

[0071] In a 250ml beaker, add 86.5g deionized water and 3.5g inulin, stir to completely dissolve the inulin, add a small amount of yeast powder, stir and ferment for 3.5h at 35℃ water bath temperature, add 8.0g silane coupling agent at room temperature KH-570, add a few drops of 10% nitric acid to adjust the pH of the system to about 4, continue to stir for 2.0h, and finally add 1.0g zirconium nitrate and 1.0g nano silica sol, stir for 3h to get the composite inulin Surface treatment liquid for galvanized sheet.

[0072] For a mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com