Anti-impact composite kerb and preparation method thereof

A curbstone and impact-resistant technology, applied in the field of road construction materials, can solve the problems of compressive and impact-resistant performance to be improved, and achieve the effects of avoiding repeated firing, long service life and strong impact-resistant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

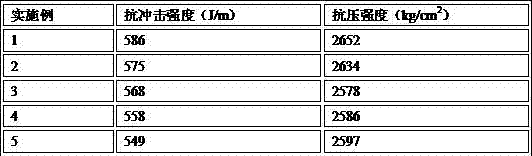

Examples

Embodiment 1

[0024] An impact-resistant composite curbstone comprises a facing layer and a base layer, and the facing layer includes the following raw materials in parts by weight: 86 parts of waste plastics, 22 parts of fly ash, 15 parts of silicon dioxide, 6 parts of SBS modified asphalt, Stabilizer aluminum stearate 5 parts, coupling agent vinyltrimethoxysilane 3 parts, antioxidant BHT 1 part.

[0025] The base layer includes the following raw materials in parts by weight: 52 parts of Portland cement, 25 parts of quartz sand, and 6 parts of construction rubber powder.

[0026] The preparation method of the impact-resistant composite curbstone comprises the following steps:

[0027] (1) Preparation of the facing layer: Mix and stir the raw materials of the facing layer according to parts by weight, and dry them at 50-60°C for 10-20 minutes. The compression ratio is 3:1, and the extrusion pressure is 12Mpa. The extruded granules are put into a forming mold, moved into a hot press with a...

Embodiment 2

[0031] An impact-resistant composite curbstone comprises a facing layer and a base layer, and the facing layer includes the following raw materials in parts by weight: 88 parts of waste plastics, 20 parts of fly ash, 16 parts of silicon dioxide, 10 parts of SBS modified asphalt, 6 parts of stabilizer calcium stearate, 4 parts of coupling agent vinyl triperoxy tert-butyl silane, 2 parts of antioxidant 1010.

[0032] The base layer includes the following raw materials in parts by weight: 55 parts of Portland cement, 26 parts of quartz sand, and 8 parts of building rubber powder.

[0033] The preparation method of the impact-resistant composite curbstone comprises the following steps:

[0034] (1) Preparation of the facing layer: Mix and stir the raw materials of the facing layer according to parts by weight, and dry them at 50-60°C for 10-20 minutes. The compression ratio is 4:1, and the extrusion pressure is 10Mpa. The extruded granules are put into a forming mold, moved into...

Embodiment 3

[0038] An impact-resistant composite curbstone comprises a facing layer and a base layer, and the facing layer includes the following raw materials in parts by weight: 95 parts of waste plastics, 28 parts of fly ash, 13 parts of silicon dioxide, 10 parts of SBS modified asphalt, Stabilizer potassium stearate 6 parts, coupling agent vinyltriacetoxysilane 5 parts, antioxidant 1076 3 parts.

[0039] The base layer includes the following raw materials in parts by weight: 55 parts of Portland cement, 23 parts of quartz sand, and 8 parts of building rubber powder.

[0040] The preparation method of the impact-resistant composite curbstone comprises the following steps:

[0041] (1) Preparation of the facing layer: Mix and stir the raw materials of the facing layer according to parts by weight, and dry them at 50-60°C for 10-20 minutes. The compression ratio is 5:1, and the extrusion pressure is 12Mpa. The extruded granules are put into a forming mold, moved into a hot press with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com