65nm technology-based super-steep reverse-doping radiation-proof MOS field-effect tube

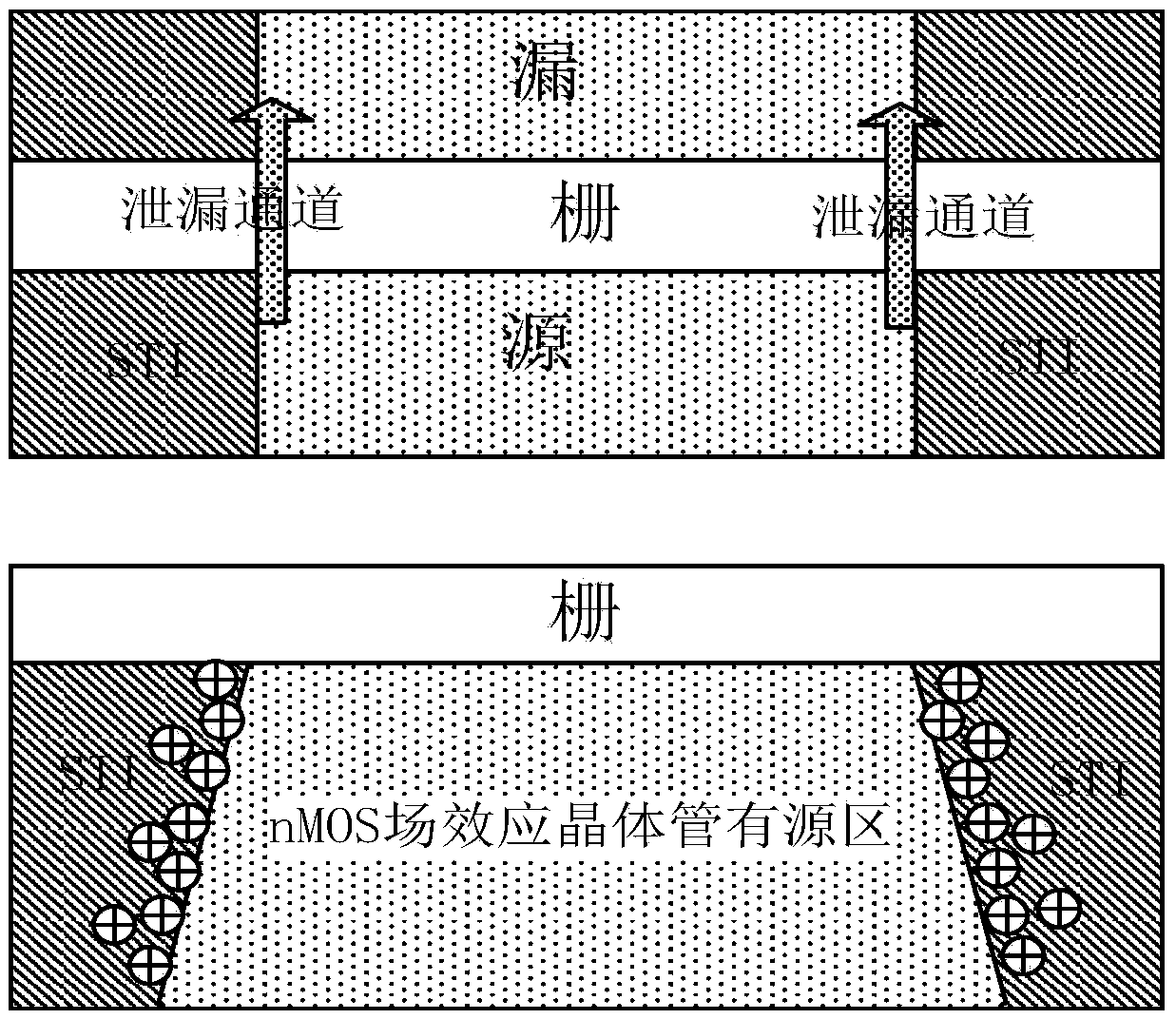

A field effect transistor and reverse doping technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problem of poor anti-radiation characteristics of nMOS field effect transistors, reduced threshold voltage of nMOS field effect transistors, and off-state leakage Current increase and other issues, to achieve the effect of improving the anti-radiation characteristics, improving the anti-radiation performance, and reducing the off-state leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

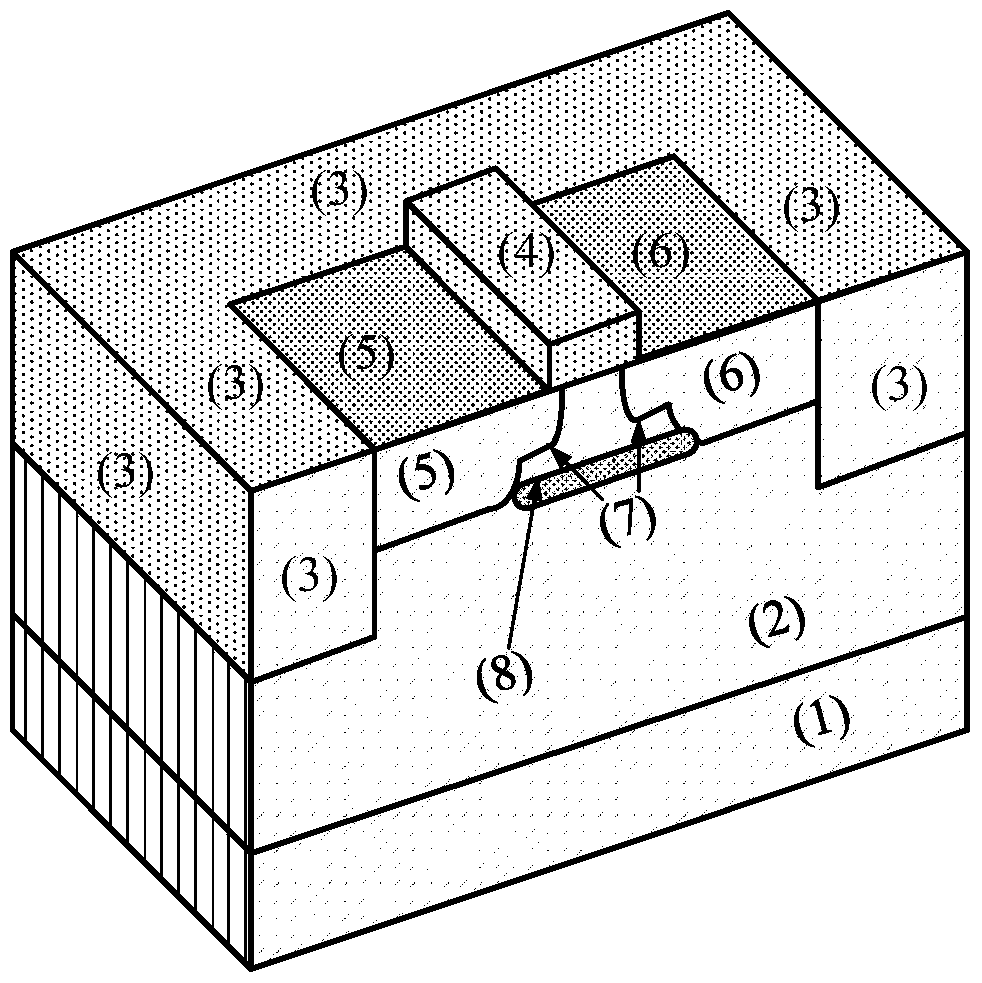

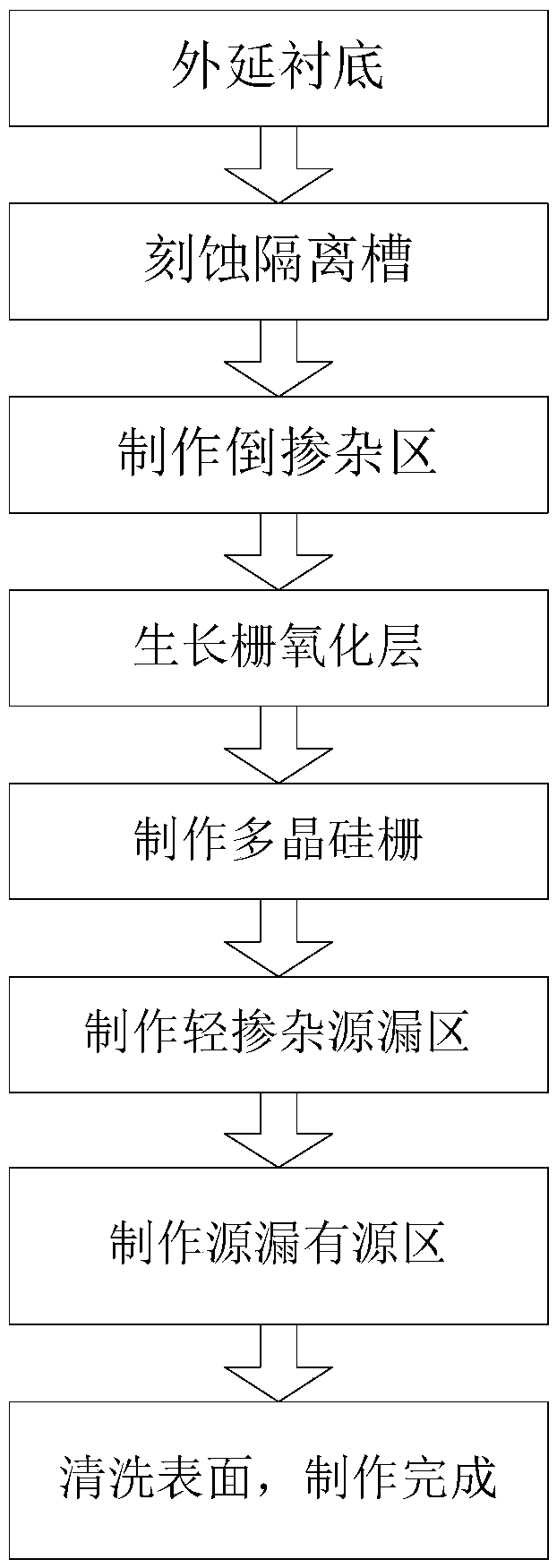

[0040] Example 1: Making a substrate with a doping concentration of 2×10 17 cm -3 , the doping concentration of the source and drain regions is 1×10 19 cm -3 , the diffusion length of the source and drain regions is 50nm, and the ultra-steep retrograde doping concentration is 6×10 17 cm -3 , a 65nm nMOS field effect transistor with an ultra-steep inverse doping depth of 58nm and an ultra-steep inversion length of 5nm.

[0041] Step 1, growing an epitaxial layer.

[0042] First use the method of chemical vapor deposition to SiH at a temperature of 650 °C 4 growing an epitaxial layer with a thickness of 600nm in the (100) crystal direction of the P-type Si substrate as a reactant;

[0043] Then doped with 2×10 by diffusion process 17 cm -3 The concentration of boron ions forms a p-type doped region with a depth of 100nm on the surface of the epitaxial layer to adjust the channel concentration.

[0044] Step 2, etching the isolation groove.

[0045] First grow thin SiO ...

example 2

[0076] Example 2: Making a substrate with a doping concentration of 5×10 17 cm -3 , the doping concentration of the source and drain regions is 3×10 19 cm -3 , the diffusion length of the source and drain regions is 55nm, the diffusion length of the source and drain regions is 50nm, and the ultra-steep retrograde doping concentration is 1×10 18 cm -3 , a 65nm nMOS field effect transistor with an ultra-steep inverse doping depth of 54nm and an ultra-steep inversion length of 20nm.

[0077] Step 1, growing an epitaxial layer.

[0078] 1.1) Using the chemical vapor deposition method at a temperature of 600 ° C to SiH 4 An epitaxial layer with a thickness of 800nm is grown on a P-type substrate as a reactant;

[0079] 1.2) Doping 5×10 by diffusion process 17 cm -3 The concentration of boron ions forms a p-type doped region with a depth of 150nm on the surface of the epitaxial layer to adjust the channel concentration.

[0080] Step 2, etching the isolation groove.

[0...

example 3

[0117] Example 3: Making a substrate with a doping concentration of 9×10 17 cm -3, the doping concentration of the source and drain regions is 5×10 19 cm -3 , the diffusion length of the source and drain regions is 60nm, and the ultra-steep retrograde doping concentration is 2×10 18 cm -3 , a 65nm nMOS field effect transistor with an ultra-steep inverse doping depth of 53nm and an ultra-steep inversion length of 27nm.

[0118] Step a, growing an epitaxial layer.

[0119] SiH was deposited at a temperature of 500 °C by chemical vapor deposition 4 An epitaxial layer with a thickness of 1000nm is grown on a P-type substrate as a reactant; doped with 9×10 17 cm -3 The concentration of boron ions forms a p-type doped region with a depth of 150nm on the surface of the epitaxial layer to adjust the channel concentration.

[0120] Step b, etching the isolation groove.

[0121] Thin SiO with a thickness of 5 nm was grown on the epitaxial layer by a dry oxygen oxidation process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com