Preparation method of special-shaped section wire titanium alloy spring

A technology of titanium alloy springs and special-shaped cross-sections, which is applied in the manufacture of springs from wires, wire processing, and applications. It can solve the problems of low stiffness coefficients of titanium alloy springs, increase the cross-sectional area of wire materials, stabilize performance, and make springs difficult to control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the titanium alloy ingot is forged into a φ70 mm forged rod, and the forged rod is rolled into a square wire with a section of 12.5 mm×12.5 mm by special-shaped rolling equipment.

[0029] (1) Forging: At 1170°C, heat preservation for 3 hours, using forging process, forging titanium alloy ingots into φ70mm rods;

[0030] (2) Hot rolling: heat preservation at 900° C. for 1 hour, and use hot rolling process to roll the titanium alloy forged rod into a square wire with a section of 12.5 mm×12.5 mm through rolling equipment.

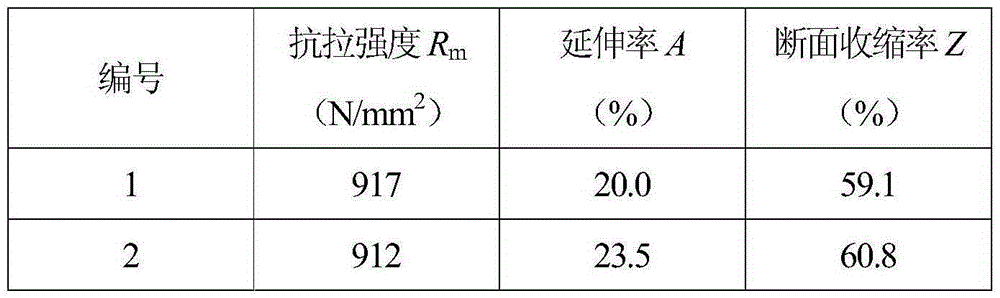

[0031] (3) Solution treatment: solution treatment was carried out on the rolled bar at 830°C for 10 minutes, and the tensile properties of the solid solution wire were measured. See Table 1 for the specific results.

[0032] Table 1 Tensile properties of wire after solid solution treatment

[0033]

[0034] It can be seen from Table 1 that the plasticity of the wire after solution treatment is good, especially the reduction of ...

Embodiment 2

[0040]In this embodiment, the titanium alloy ingot is forged into a forged rod with a diameter of 60 mm, and the forged rod is rolled into a hexagonal wire with a side length of 7.5 mm by special-shaped rolling equipment.

[0041] (1) Forging: At 1140°C, heat preservation for 4 hours, using forging process, forging titanium alloy ingots into φ60mm rods;

[0042] (2) Hot rolling: heat preservation at 880°C for 2 hours, using a hot rolling process, rolling the titanium alloy forged rod through rolling equipment into a hexagonal wire with a side length of 7.5 mm;

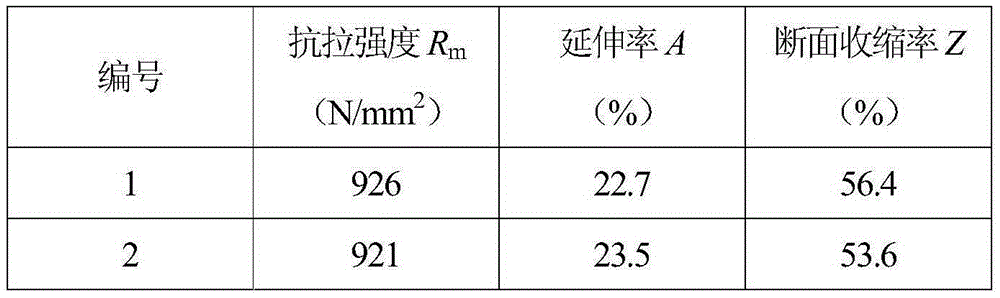

[0043] (3) Solution treatment: heat preservation at 820° C. for 15 minutes, carry out solution treatment on the wire, and measure the tensile properties of the wire in solution state. The specific results are shown in Table 3.

[0044] Table 3 Tensile properties of wire after solid solution treatment

[0045]

[0046] It can be seen from Table 3 that the plasticity of the wire after solution treatment is good, espe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com