Horizontal general plug

A universal plug and one-shaped technology, applied in the direction of contact parts, fixed/insulated contact components, electrical components, etc., can solve the problems of inconvenient operation, a certain amount of effort, and not on the same straight line, etc., to achieve convenient operation, plug in Effort-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

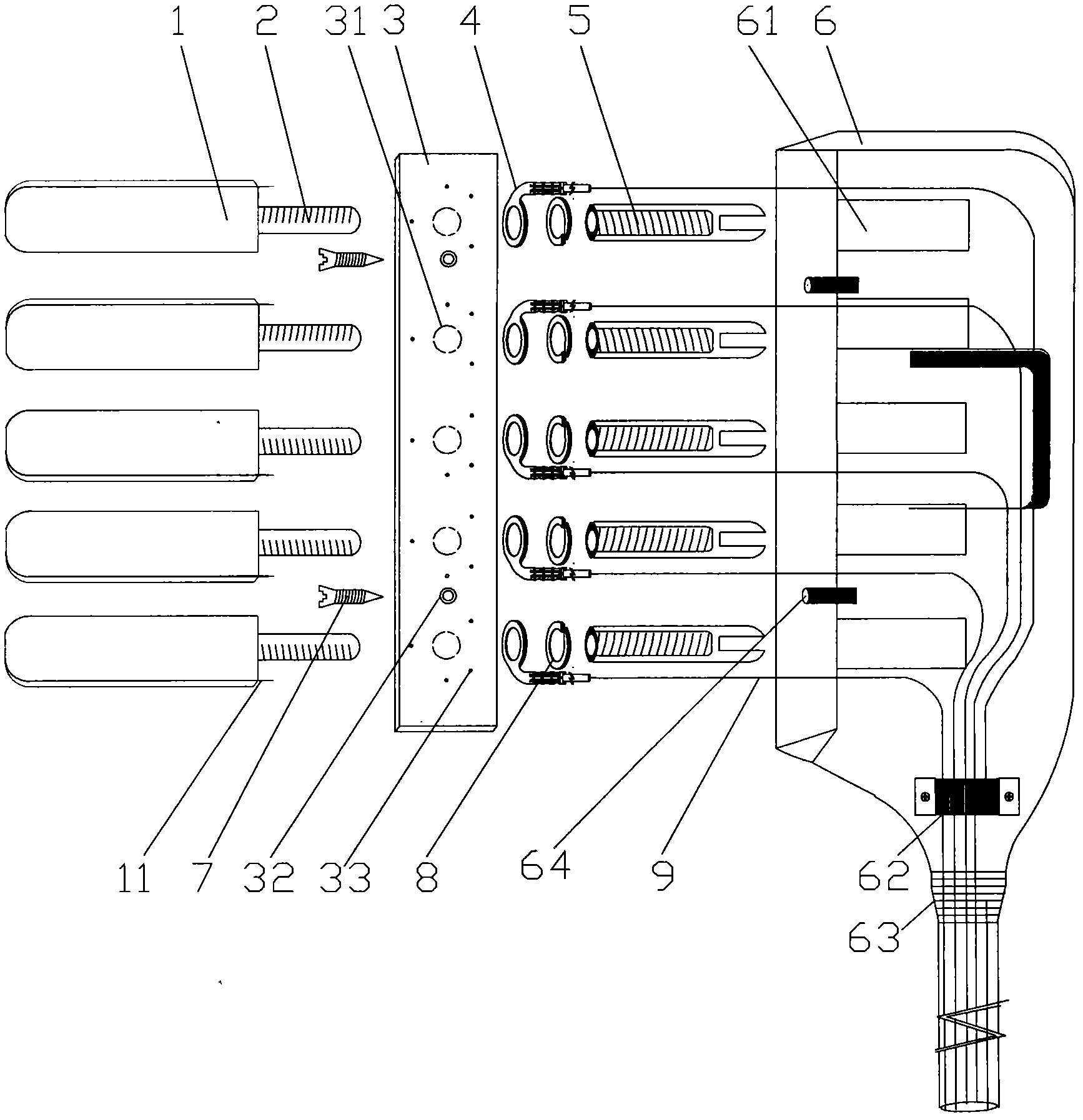

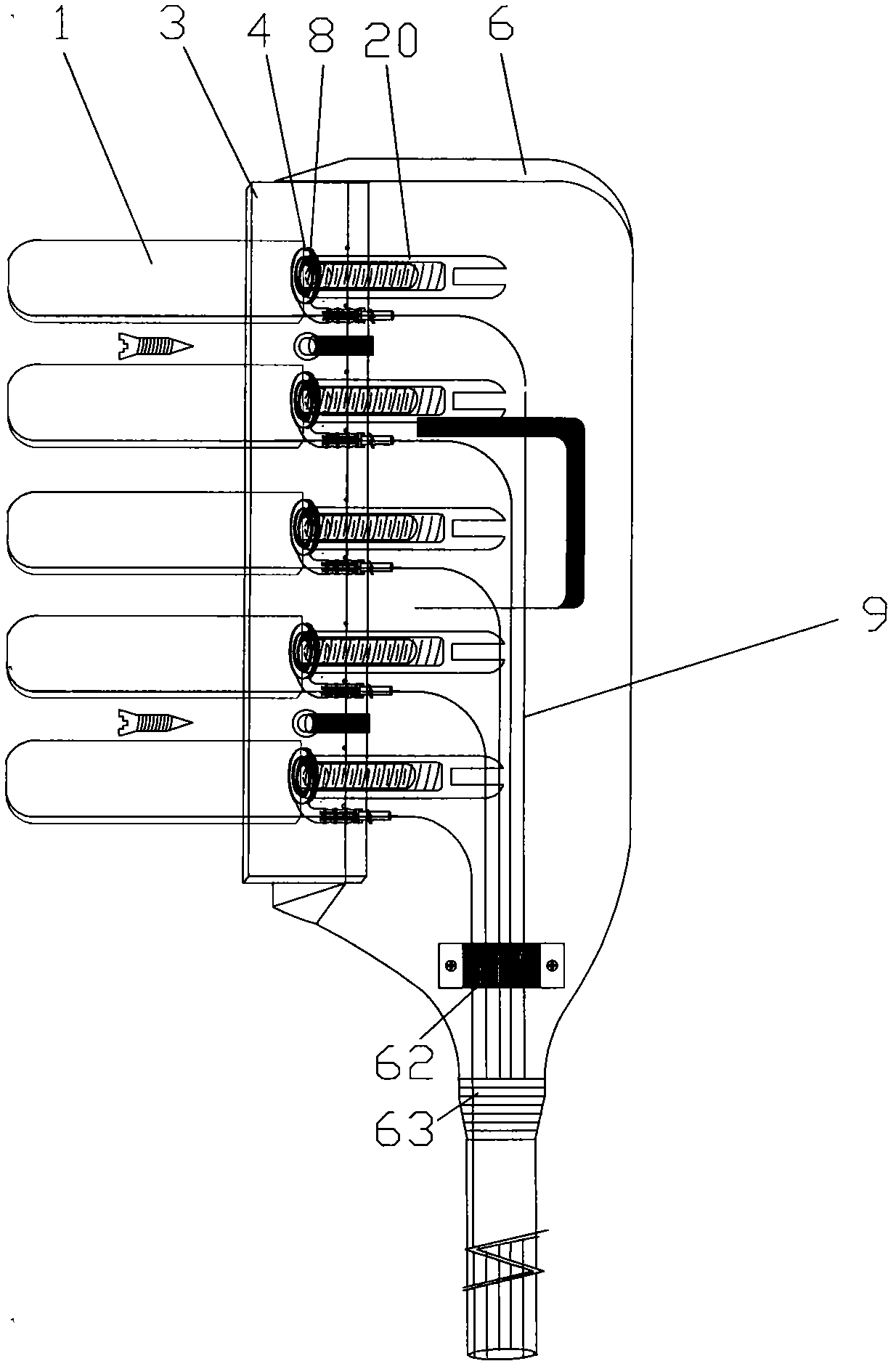

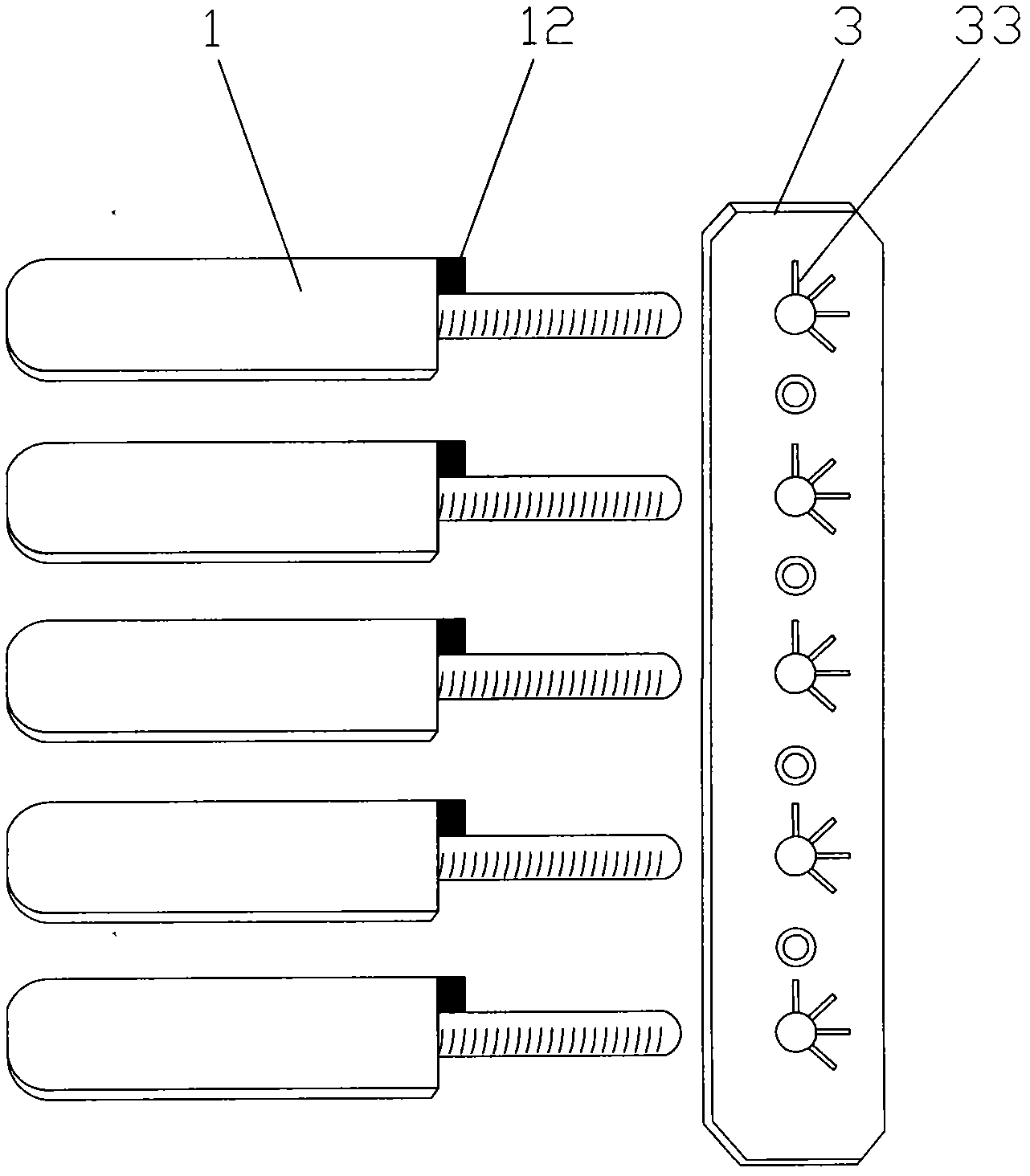

[0033] Examples, see figure 1 , figure 2 As shown, a kind of inline universal plug of the present invention, comprises the shell 6 that front end is set as opening, mounting plate 3, five pins, five wiring flat pads 4 and five fastening reeds 8; There are two parts, the sheet body 1 and the circular rod body 20; the mounting plate 3 fits at the opening of the housing 6, and the mounting plate 3 is provided with a plurality of mounting holes 31 arranged in a straight line along the length direction of the mounting plate 3; the housing 6 There are a plurality of pin receiving grooves 61 arranged in a line along the length direction of the shell; the circular rod body 20 of the pin passes through the mounting hole 31 from the outside of the mounting plate, and is positioned in the pin receiving groove 61 of the shell 6, To make the flat body 1 of the pin fit on the outside of the mounting plate 3; or, the circular rod body 20 of the pin can also pass through the mounting hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com