Baffle structure for cast aluminum rotor of high-voltage motor

A high-voltage motor, baffle structure technology, applied in the magnetic circuit shape/style/structure, magnetic circuit rotating parts and other directions, can solve the blockage of the rotor axial ventilation, the high temperature of the stator and rotor core, and the cooling effect. It is not easy to miss, improve reliability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

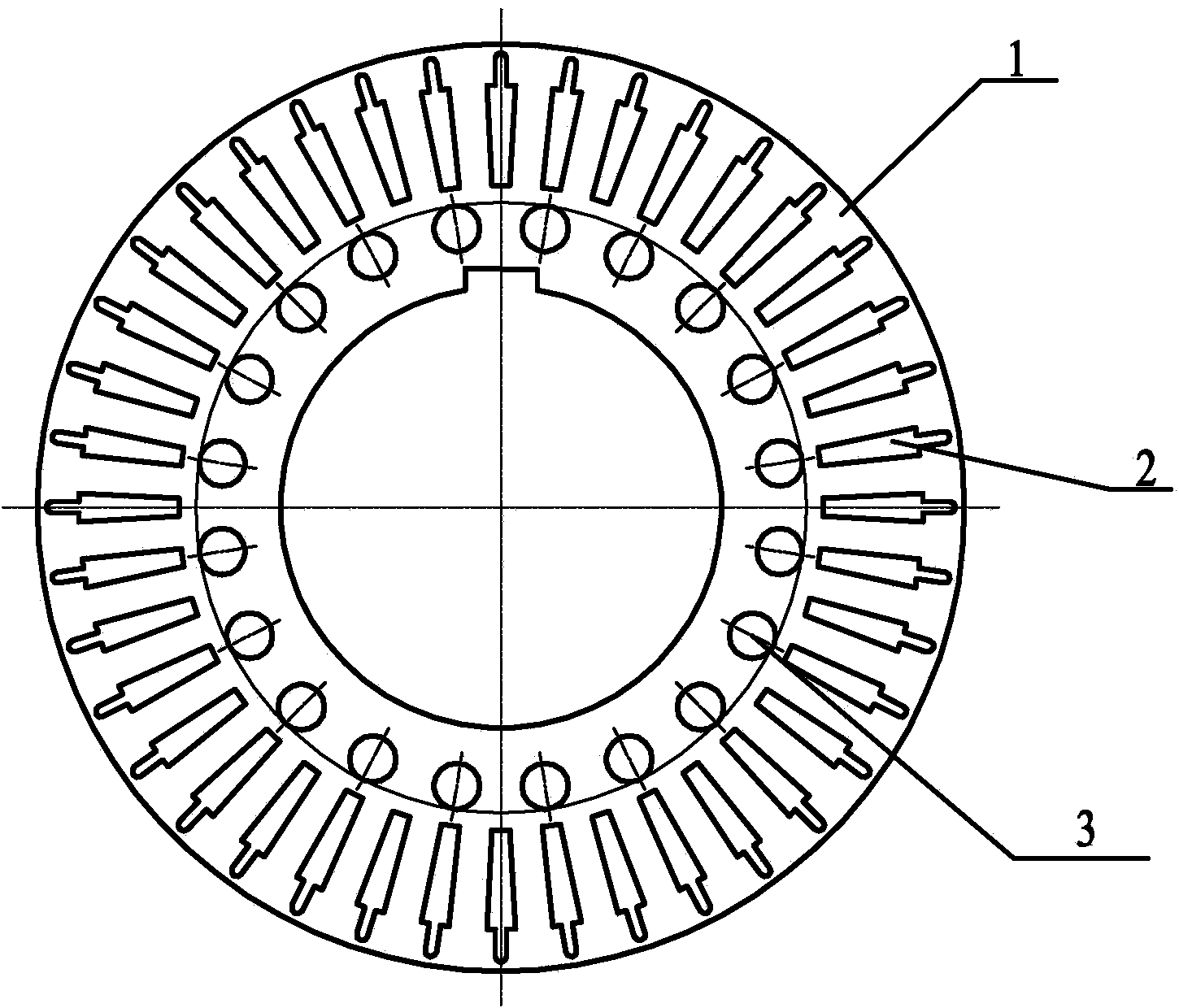

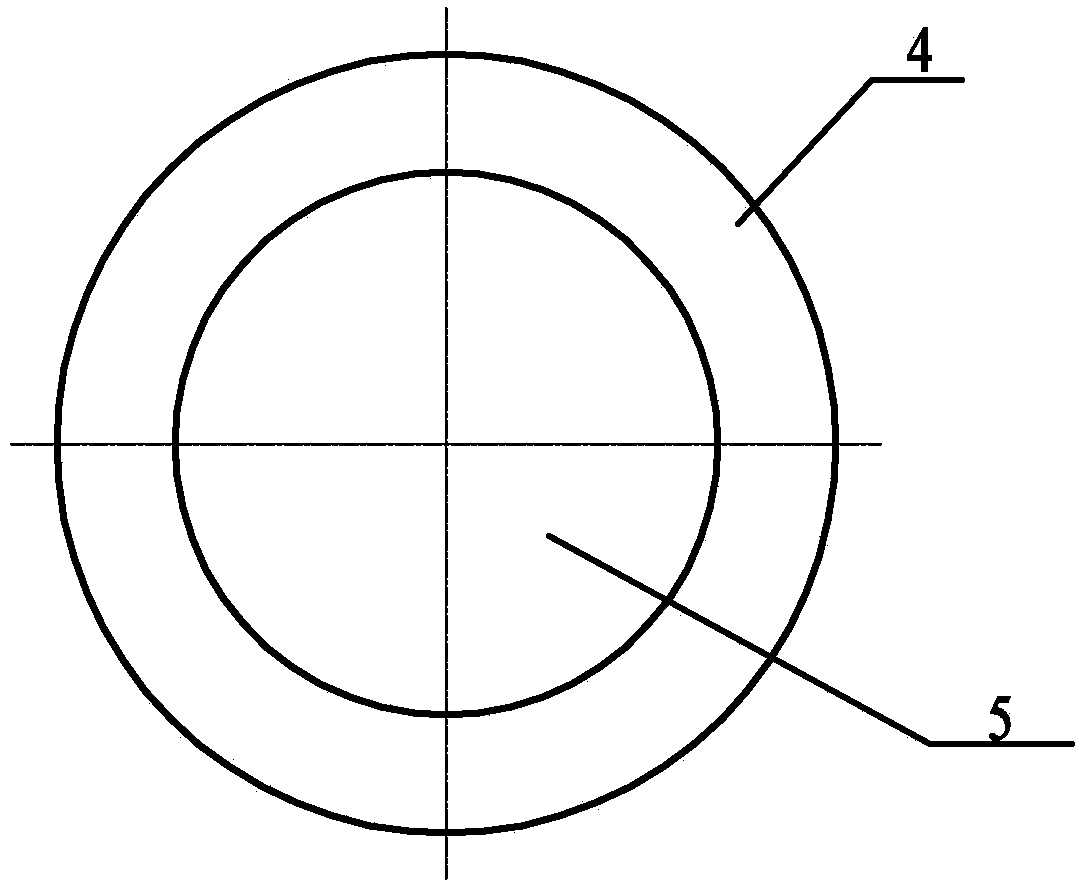

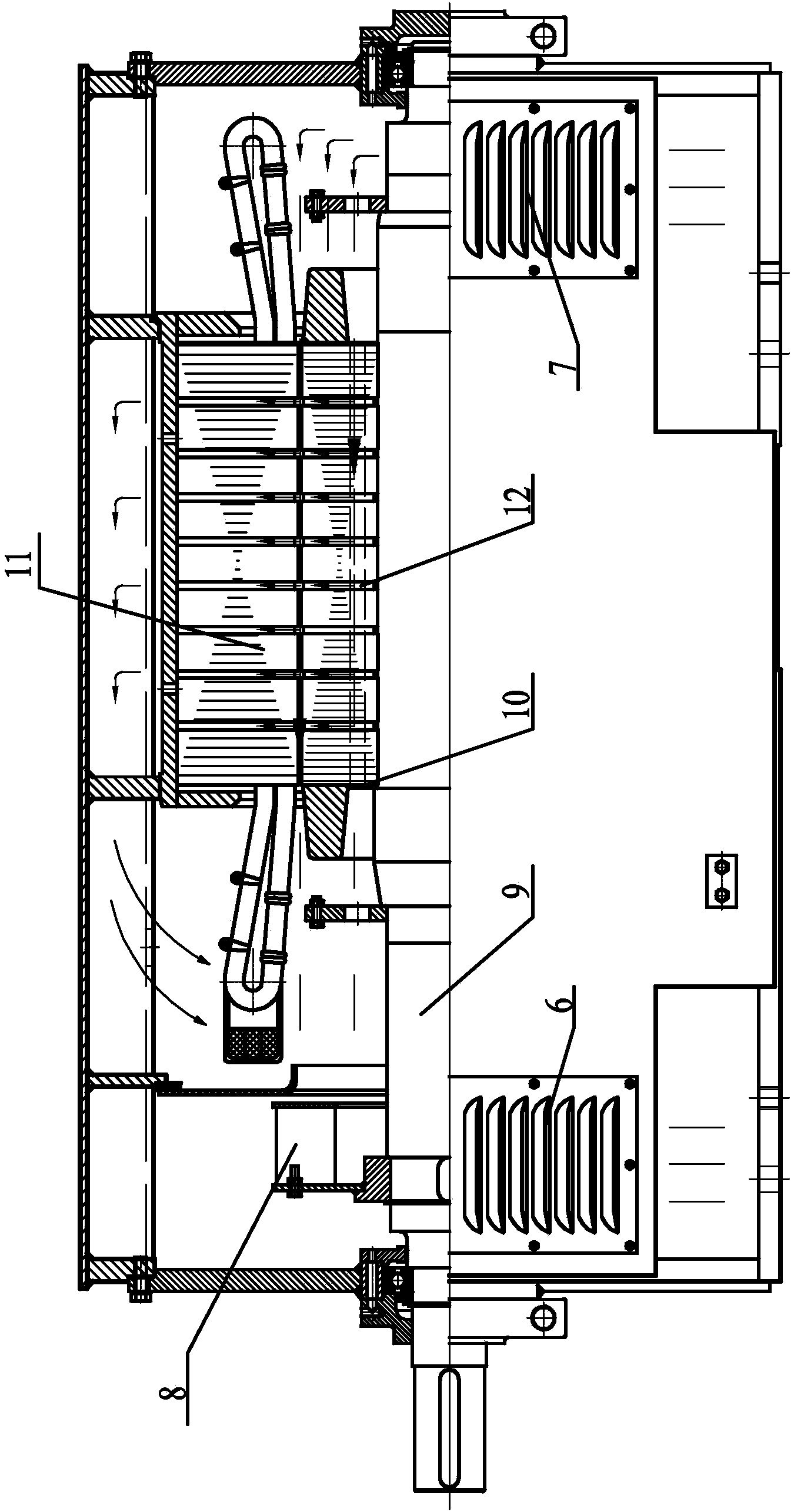

[0014] Such as figure 1 , figure 2 and image 3 As shown: In order to avoid the phenomenon of missing the second rotor ventilation slot plate or putting the second rotor ventilation slot plate upside down during the assembly process of the cast aluminum rotor, the baffle plate 10 of the present invention includes a baffle plate body 4, the baffle plate The center area of the plate body 4 is provided with a mounting hole 5, the aperture of the mounting hole 5 is the same as the inner diameter of the rotor punching body 1, and the baffle body 4 on the outer ring of the mounting hole 5 can block the vent hole on the rotor punching body 1 3.

[0015] Specifically, for a high-pressure cast aluminum rotor motor with a box-type IP23 structure, the diameter of the mounting hole 5 is 195 mm, and the outer diameter of the baffle body 4 is 280 mm. The baffle 10 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com