Coal mine inclined shaft standby explosion door device

A technology for explosion-proof doors and inclined shafts, which is applied to mining equipment, mining equipment, sealing devices, etc., and can solve the problems of flushing away from the wellhead, casualties of underground personnel, and inability to isolate underground airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

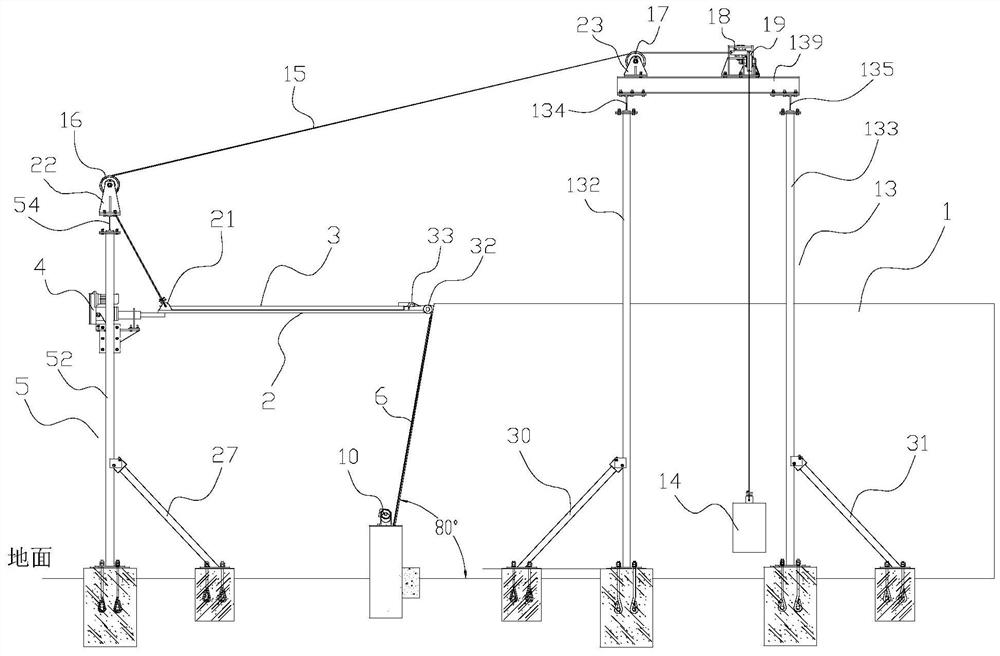

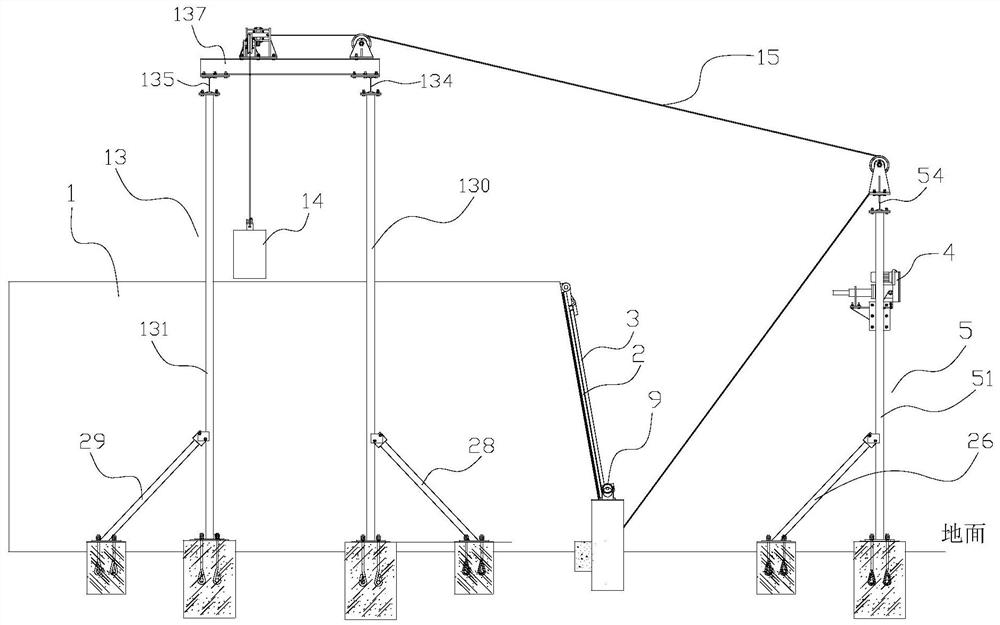

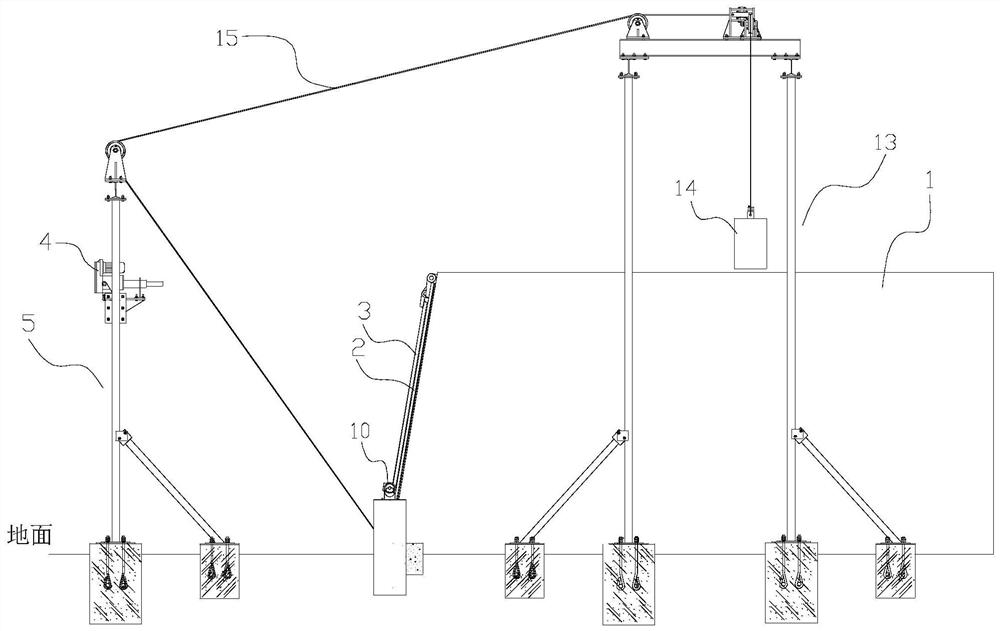

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as Figure 1 to Figure 10 The shown backup explosion-proof door device for an inclined shaft in a coal mine includes a concrete box 1, a door leaf 2, a window leaf 3, two first electric push rod mechanisms 4, a first bracket 5, a second electric push rod mechanism 9, and a third electric push rod mechanism. Electric push rod mechanism 10, first locking plate 11, second locking plate 12, second support 13, electric control system and two sets of counterweight systems. The electric control system (not shown in the figure) is used to provide power for two first electric push rod mechanisms 4, one second electric push rod mechanism 9, and one third electric push rod mechanism 10, and at the same time receive the remote control command, and according to the remote control command, control the extension and retraction of the push rods of the two first electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com