Ventilating tower wind-power axial flow fan

A technology of axial fans and ventilation towers, which is applied to wind power generation, wind engines, and wind engines at right angles to the wind direction, etc., which can solve the problem of the impossibility of wind turbines intercepting wind energy at a comparable technical level and the low utilization efficiency of wind energy resources, etc. Problems, achieve the effect of reducing operating costs and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

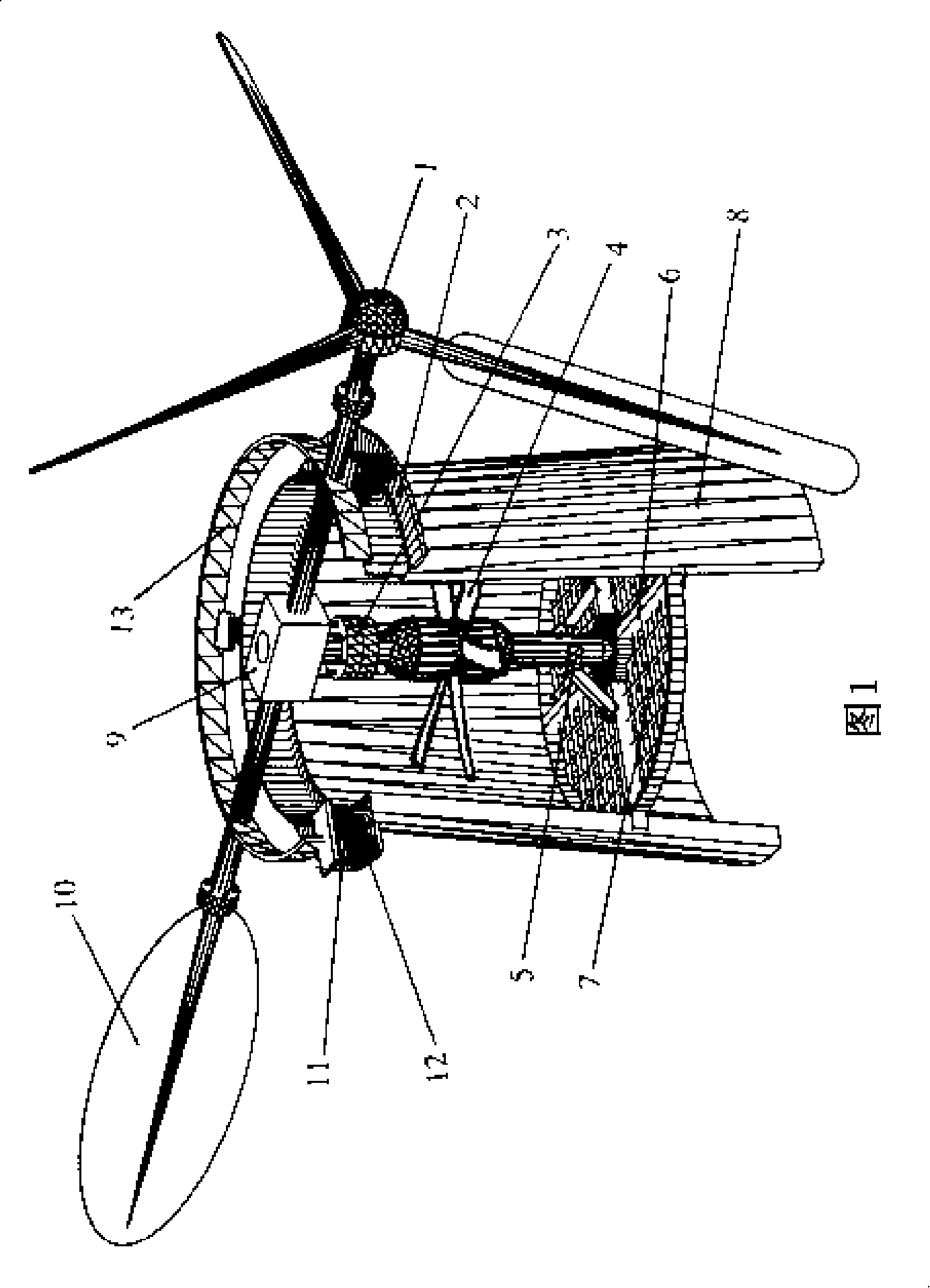

[0020] As shown in FIG. 1 , the wind turbine 1 is a horizontal axis wind turbine. The main shaft of the wind turbine 1 is connected to the input shaft of the gearbox 9, the input shaft and the output shaft of the gearbox 9 are at right angles, the horizontal rotation of the wind turbine is converted into vertical rotation through the gearbox 9, and the axial flow fan is driven by the coupling 3 4 rotates in the ventilation tower 8, and according to the installation direction of the impeller of the axial flow fan 4, the air supply or exhaust is realized from the ventilation tower 8 to the tunnel.

[0021] In order to adapt to the change of the outdoor wind direction, the wind turbine 1 is installed on the movable support 13 on the ventilation tower 8 , and the movable support 13 can rotate along the radial direction of the ventilation tower 8 . And on the movable support 13 at the other end of the axial direction of the main shaft of the wind turbine, a guide fin 10 is installe...

Embodiment 2

[0026] For an environment where the wind direction is stable and does not change much, the guide rail 2, the radial guide wheel 11, the axial guide wheel 12, the movable support 13 and the guide tail 10 can be eliminated, and the main shaft of the wind turbine 1 can be passed through the bearing seat. It is directly installed on the tower body of the ventilation tower 8, and the main shaft of the wind turbine 1 is connected with the main shaft of the axial flow fan through a gear box. The blades of the wind turbine 1 are fixed in a direction corresponding to the wind direction.

Embodiment 3

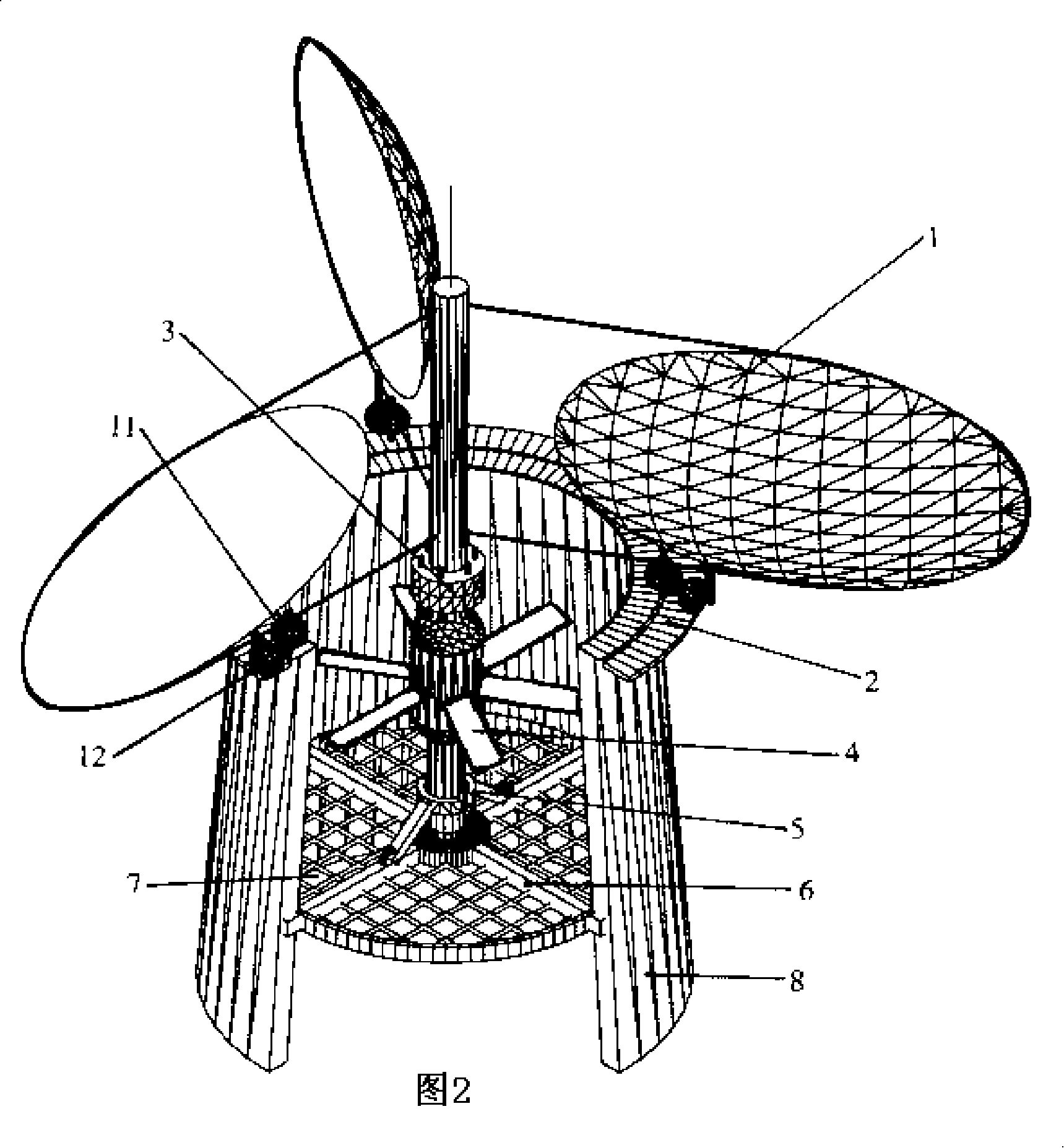

[0028] As shown in FIG. 2 , the wind turbine 1 adopts a vertical axis wind turbine, and is installed on the coaxial line between the mouth of the ventilation tower 8 and the axial flow fan 4 inside the tower. The shaft coupling 3 is directly connected to the axial flow fan 4 to drive the blades of the axial flow fan 4 to rotate. When the wind turbine 1 intercepts the wind energy from the outdoor environment, it directly transmits the axial mechanical motion to the axial flow fan 4 through the coupling 3, and drives the impeller of the axial flow fan 4 to rotate, so that the ventilation tower 8 can discharge air to the outside of the tunnel or inward. air supply.

[0029] In order to make the rotation of the wind turbine 1 stable, a radial positioning wheel 11 and an axial positioning wheel 12 are installed under the blades of each wind turbine 1. The radial positioning wheel 11 is in contact with the outer wall of the ventilation tower 8 for positioning, and the axial position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com