Method and device for carrying out differential temperature incremental forming on aviation light alloy plates

A progressive forming and light alloy technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low forming quality, uneven deformation, low forming precision, etc., achieve high production efficiency, improve deformation uniformity, Effect of improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

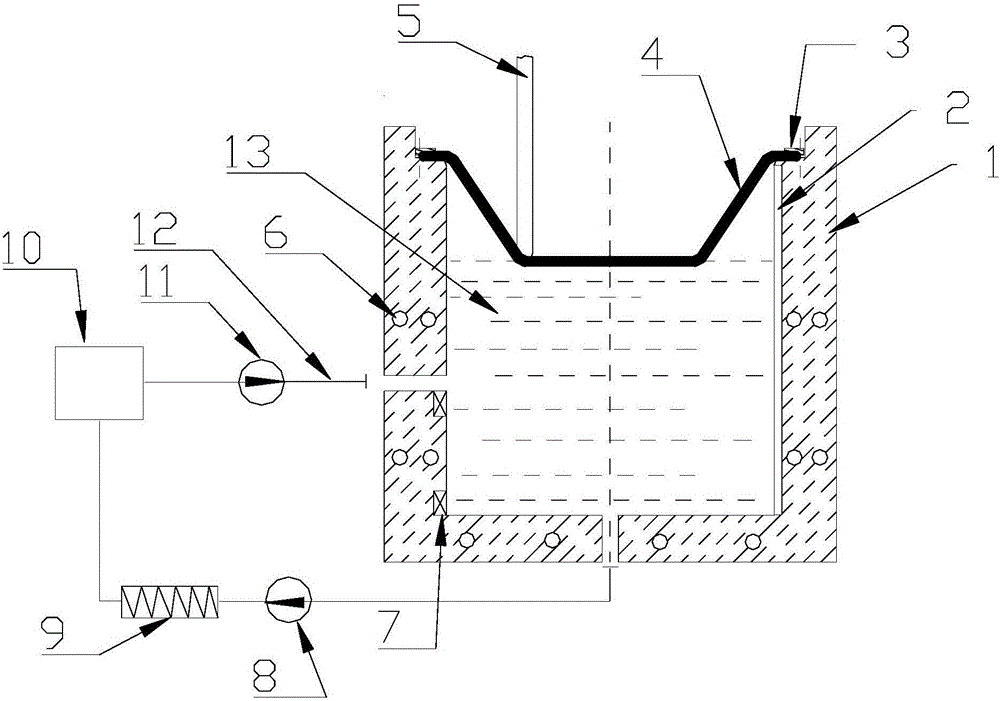

[0022] The first step is to fix the 2017 aluminum alloy plate with a side length of 150mm and a thickness of 1mm to the support base through a pressure plate;

[0023] The second step is to inject heat conduction oil into the heat conduction oil tank until the heat conduction oil contacts the plate;

[0024] The third step is to use the heating resistor in the support base to heat the heat transfer oil to 250°C and keep it warm for a period of time;

[0025] The fourth step is to import the compiled conical trajectory G code into the CNC progressive forming machine tool. After the temperature of the plate reaches 250°C, add lubricating oil at the forming position to perform differential temperature progressive forming on the plate; The liquid level detection and control system measures the height of the heat transfer oil liquid level in real time, and realizes the dynamic adjustment of the liquid level height, so that the unformed part is always in contact with the heat transf...

Embodiment 2

[0028] The first step is to fix the magnesium alloy plate with a side length of 150mm and a thickness of 1mm to the support base through a pressing plate;

[0029] The second step is to inject heat conduction oil into the heat conduction oil tank until the heat conduction oil contacts the plate;

[0030] The third step is to use the heating resistor in the support base to heat the heat transfer oil to 280°C and keep it warm for a period of time;

[0031] The fourth step is to import the compiled G code of the square cone trajectory into the CNC incremental forming machine tool. After the temperature of the sheet reaches 280°C, add lubricating oil at the forming position to perform differential temperature progressive forming on the sheet; during the forming process, through The oil level detection and control system measures the height of the heat transfer oil in real time, and realizes the dynamic adjustment of the liquid level, so that the unformed part is always in contact ...

Embodiment 3

[0034] The first step is to fix the pure titanium plate with a side length of 150mm and a thickness of 1mm to the support base through a pressure plate;

[0035] The second step is to inject heat conduction oil into the heat conduction oil tank until the heat conduction oil contacts the plate;

[0036] The third step is to use the heating resistor in the support base to heat the heat transfer oil to 300°C and keep it warm for a period of time;

[0037] The fourth step is to import the compiled G code of the rotary trajectory whose busbar is a circular arc into the CNC progressive forming machine tool. After the temperature of the plate reaches 300°C, add lubricating oil at the forming position to perform differential temperature progressive forming on the plate; During the process, through the oil level detection and control system, the height of the heat transfer oil liquid level is measured in real time, and the liquid level height is dynamically adjusted, so that the unform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com