Laser joining apparatus and laser joining method

A joining device and joining method technology, applied in the direction of laser welding equipment, auxiliary equipment, welding/welding/cutting items, etc., can solve the problems of decomposition, swelling, heat resistance temperature, low mechanical strength, etc., and achieve the reduction of material limitations, Product cost reduction, effect of laser power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

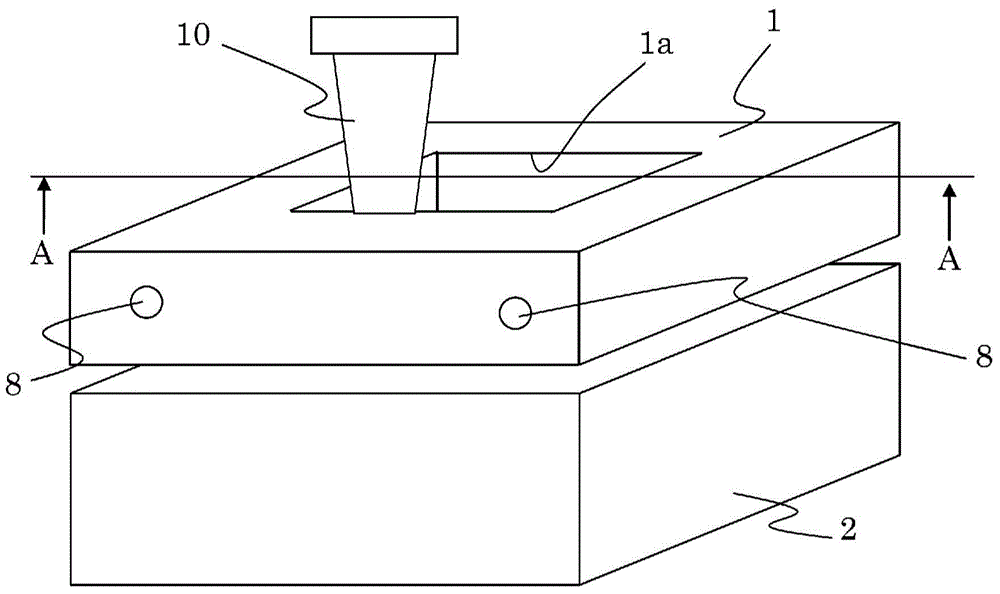

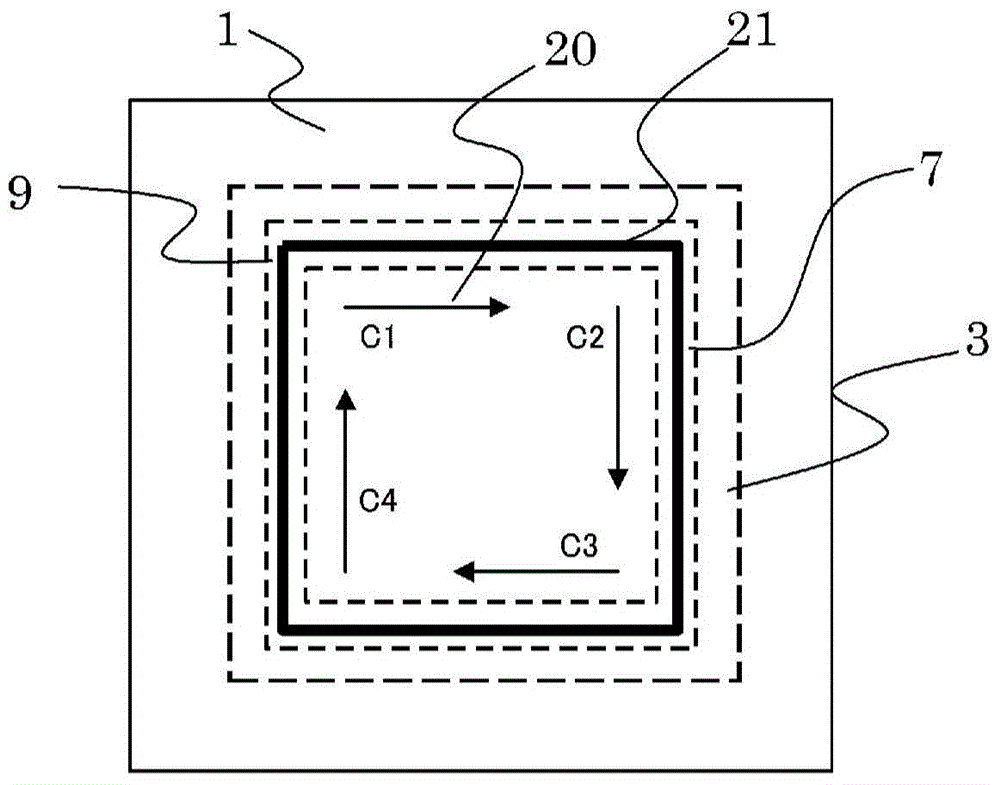

[0073] figure 1 It is a perspective view showing an embodiment of the laser bonding apparatus of a resin case and a metal material according to the present invention. The structure of this embodiment is as follows: As a pressurized fixed mold, a bonded body (resin housing and metal material) is sandwiched between a frame-shaped movable mold, that is, an upper mold 1, and a fixed mold, that is, a lower mold 2, and pressurization, heating.

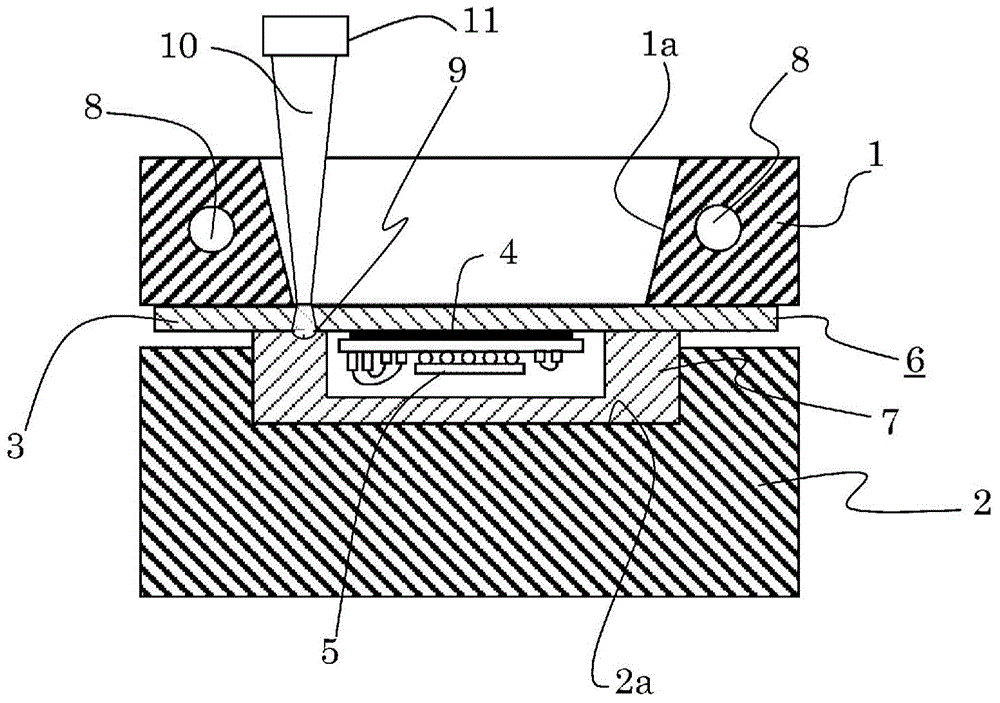

[0074] figure 2 yes means figure 1 A-A sectional view of the detailed composition of . Here, as an example, the case where the sensor member 6 is joined is demonstrated using a schematic diagram. figure 2 The upper mold 1 and the lower mold 2 hold the sensor component 6 mounted with the electronic component 5 fixed on the metal material 3 with an adhesive 4 or the like, and the resin housing 7 . In order to make the laser focusing unit part 11 close to the metal material 3, a hole part 1a is formed in the upper mold 1 in a frame shape...

Embodiment 2

[0082] Figure 4 It is a perspective illustration showing another example of the laser bonding apparatus of resin and metal. figure 1 , figure 2 of resin and laser bonding devices, for the described figure 1 The components shown in , which have the configuration and function assigned the same symbols, will not be described again.

[0083] In this embodiment, an example in which the joint shape of the resin housing and the metal material is enlarged will be described. That is, it is constituted as follows: a central portion of a frame-shaped upper die 1 is provided with a pressurizing block 30 for uniformly pressing the metal material 3 and a transparent material 31 for fixing the upper die 1 and the pressurizing block 30 ( For example, glass, etc.). The laser light 10 passes through the transparent material 31 .

[0084] Figure 5 yes means Figure 4 A-A sectional view of the detailed composition of . It is configured as follows: a transparent material 31 for fixing the...

Embodiment 3

[0087] Figure 6 It is a cross-sectional view showing another example of the resin and metal laser bonding method of the present invention. It is constituted as follows: another material 40 (metal material, ceramics, etc.) having a large light absorption rate for joining is provided on the upper surface portion of the metal material 3 to be joined. From this, it was found that the resin housing 7 and the metal material 3 can be joined uniformly with high strength by generating heat conduction in the joined metal material 3 via the other material 40 . For example, when it is desired to join aluminum and copper, by using a stainless steel material with a large laser absorption rate in the infrared region and a small thermal conductivity, the effect of high-strength and uniform bonding can be exerted with less laser irradiation energy. That is, by using another material 40 with a small thermal conductivity, the energy irradiated to the junction during heating does not diffuse wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com