Closed circulation cooling system for welder

A closed-circuit circulation and cooling system technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of intermittent shutdown, short service life of motor, low welding efficiency of welding machine, etc., and achieve low temperature rise , Guarantee welding efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

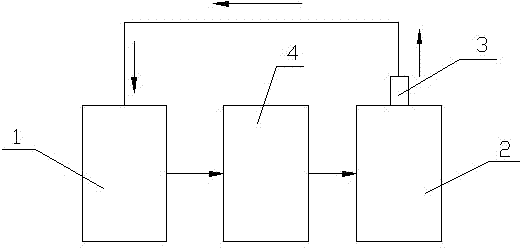

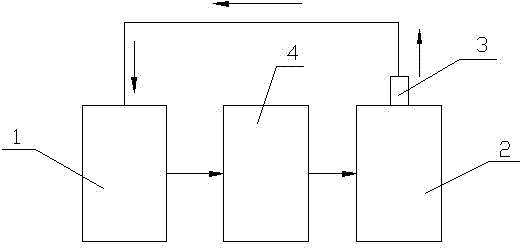

[0008] Such as figure 1 As shown, the closed-circuit circulation cooling system for a welding machine includes a welding machine main body 1 provided with a cooling channel, and a cooling device is connected outside the welding machine main body 1, and the cooling device includes a cooling liquid tank 2, which is arranged outside the cooling liquid tank 2 A booster pump 3, a refrigerator 4 is set between the main body 1 of the welding machine and the coolant tank 2, the outlet end of the coolant tank 2 is connected to the booster pump 3 through a pipeline, and the outlet end of the booster pump 3 is connected to the welder through a pipeline The inlet end of the cooling passage on the main body 1 is connected, the outlet end of the cooling passage on the welding machine main body 1 is connected with the inlet end of the refrigerator 4 through a pipe, and the outlet end of the refrigerator 4 is connected with the inlet end of the coolant tank 2 through a pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com