Method for controlling welding path of welding robot

A welding robot and welding path technology, applied in welding equipment, welding accessories, program control manipulators, etc., can solve problems such as poor weld quality and poor welding uniformity, and achieve low cost, high reliability, and simple software design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides a welding robot system and a welding path control method with simple structure, low cost, simple control mode and high reliability:

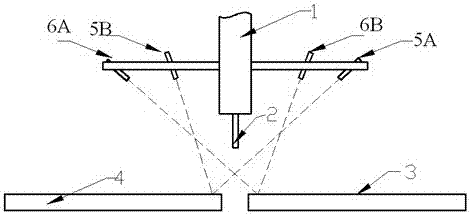

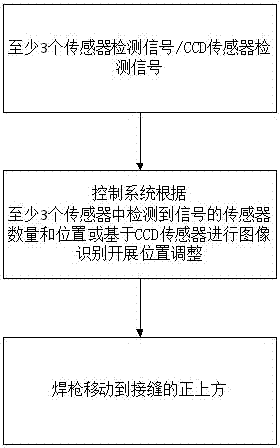

[0024] A welding robot includes a mechanical arm, a cage fixed at the end 1 of the mechanical arm, a welding torch 2 mounted on the end 1 of the mechanical arm, and an error correction system mounted on the cage. According to the instructions of the control system, the mechanical arm Drive the welding torch 2 above the seam and move along a predetermined path to complete the welding of 3 / 4 of the two plates;

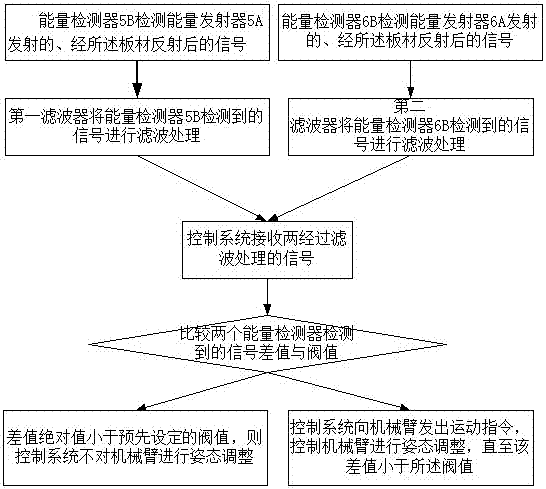

[0025] The error correction system includes first and second detection components 5 / 6 and a filter;

[0026] The detection parts 5 / 6 include energy emitters 5A\6A and energy detectors 5B\6B respectively located on one side and the other side of the welding torch 2; and, the energy emitters 5A of the first detection part and the The energy detector 6B is located on the same side of the welding torch 2;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com