Rotatable welding positioner

A welding positioner and rotary chuck technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing welding quality and increasing welding time, so as to improve welding processing quality and reduce labor. Strength, the effect of avoiding overhead welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

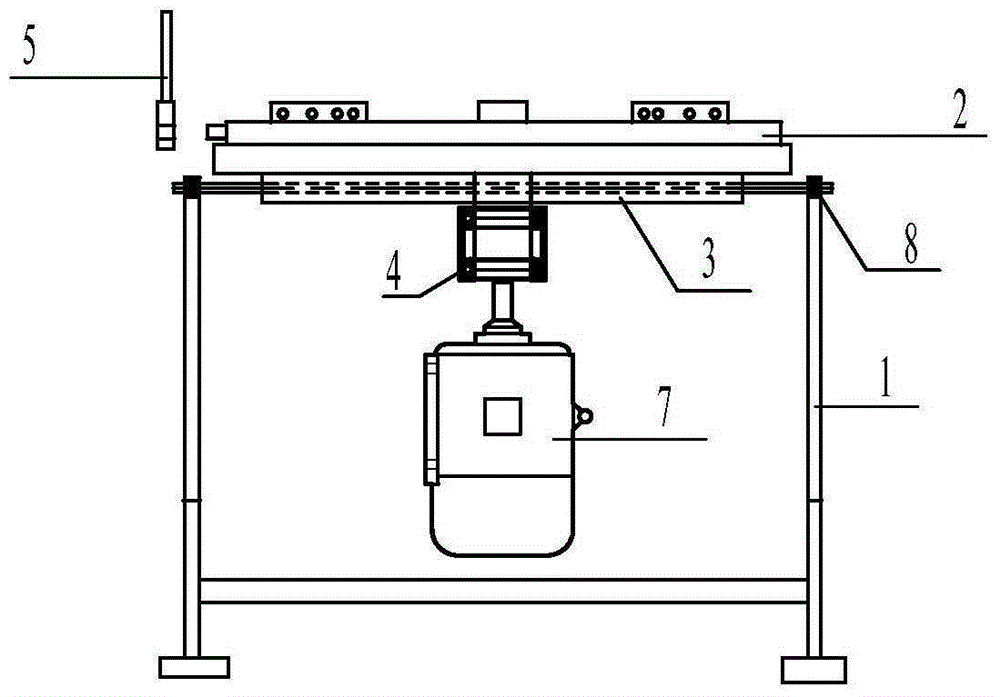

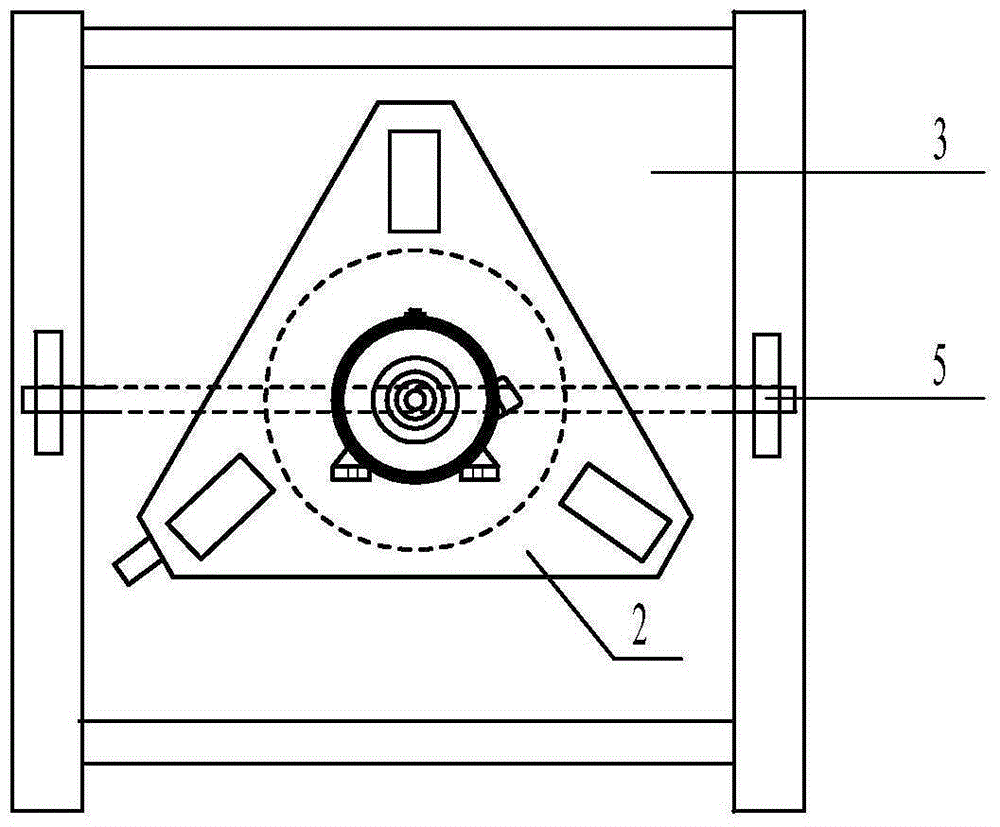

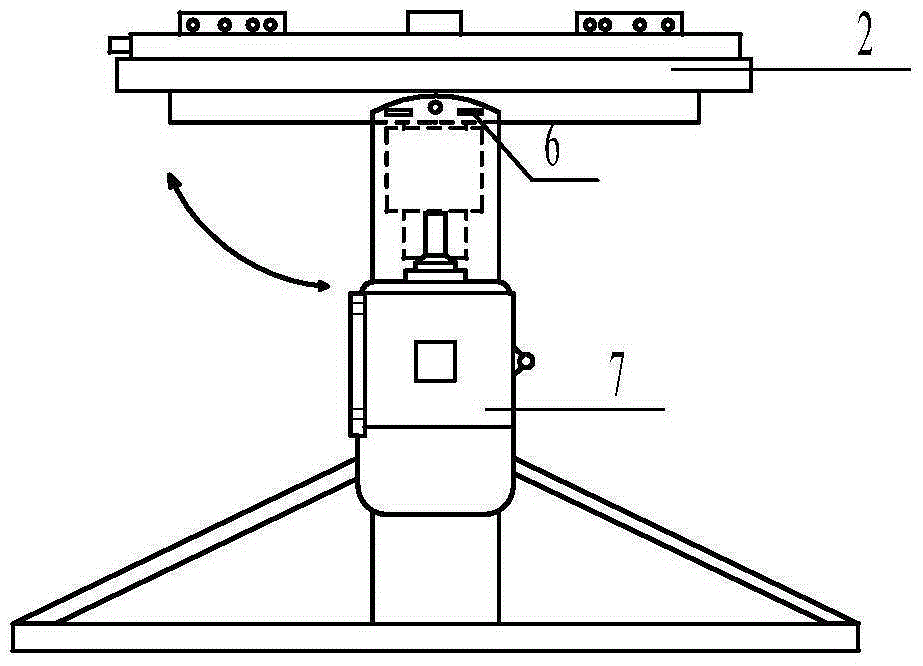

[0018] A rotatable welding positioner, the body is provided with a support frame 1, a rotatable chuck 3 is installed on the top of the support frame 1 through a rotating bearing 8, and a positioning pin 6 is provided at the top of the side of the support frame 1, and the rotatable chuck 3 A concave hole is provided at the corresponding position; the rotatable chuck 3 is provided with a coaxial three-jaw chuck 2, and the side of the three-jaw chuck 2 is symmetrically provided with a rotating handle 5, and the three-jaw chuck 2 The bottom of the motor is connected with the frequency converter and the three-phase motor 7 through the motor bearing 4.

[0019] The bottom of the support frame 1 is provided with a universal wheel, and the side of the universal wheel is provided with a fixing device. The device can be freely moved and fixed during use.

[0020] The support frame 1 and the rotatable chuck 3 are 25# channel steel. Channel steel has good welding, riveting performance a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com