Anti-collision robot welding gun

A technology of robot and robot arm, which is applied in the direction of welding rod characteristics, protective support device, electrode support device, etc., can solve the problems of workpiece welding torch damage, welding wire blockage, welding torch collision, etc., to ensure welding efficiency and prolong use. Lifespan, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

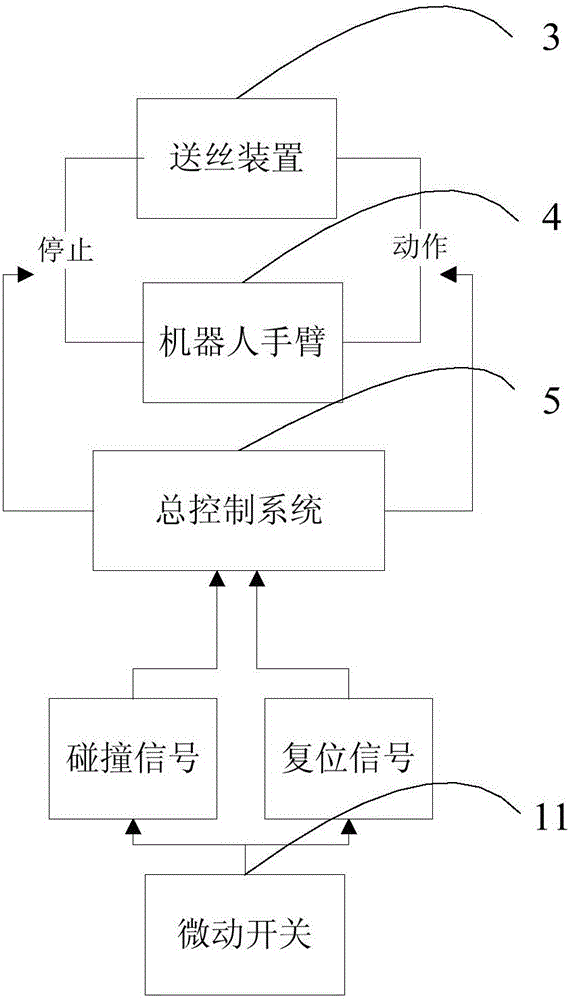

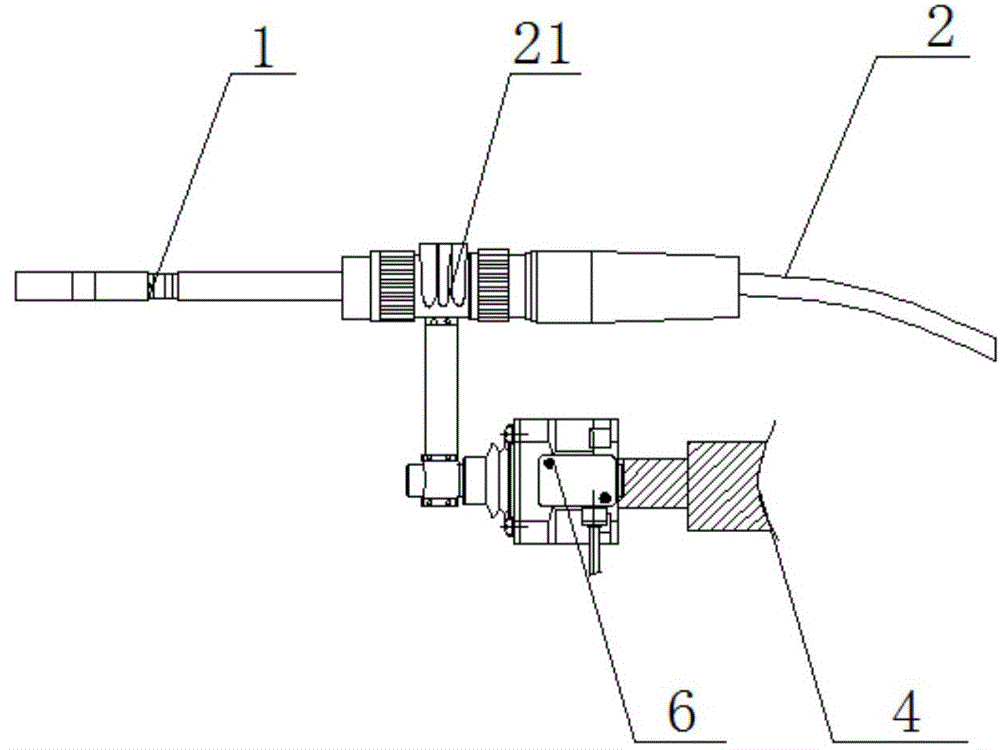

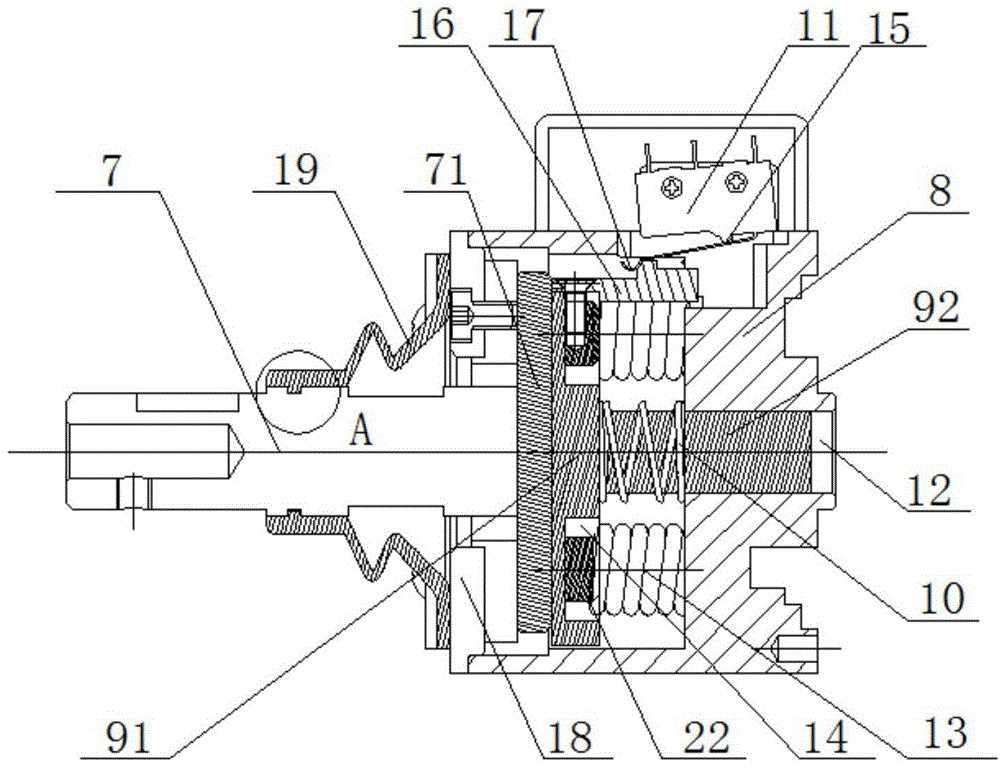

[0026] This embodiment provides a kind of anti-collision robot welding torch, such as figure 1 and figure 2 As shown, it includes a welding torch body 1, a wire feeding device 3 arranged at the rear end of the welding torch body 1 and connected by a cable 2, a robot arm 4 for controlling the action of the welding torch body 1, and a general control system 5. The wire feeding device 3 and The robot arms 4 are all connected with the total control system 5, and also include an anti-collision sensor 6, and the anti-collision sensor 6 is arranged between the welding torch body 1 and the robot arm 4. Specifically, the anti-collision sensor 6 is fixedly arranged on The robot arm 4 terminal, the front end of the anti-collision sensor 6 is connected with the welding torch body 1 through the claw 21, the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com