Welding method of CO2 gas shielded welding for solid welding wire with diameter of phi 1.6

A technology of gas shielded welding and welding methods, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of unguaranteed welding quality, unadaptable welding parameters, difficult operation, etc., so as to ensure welding efficiency and welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

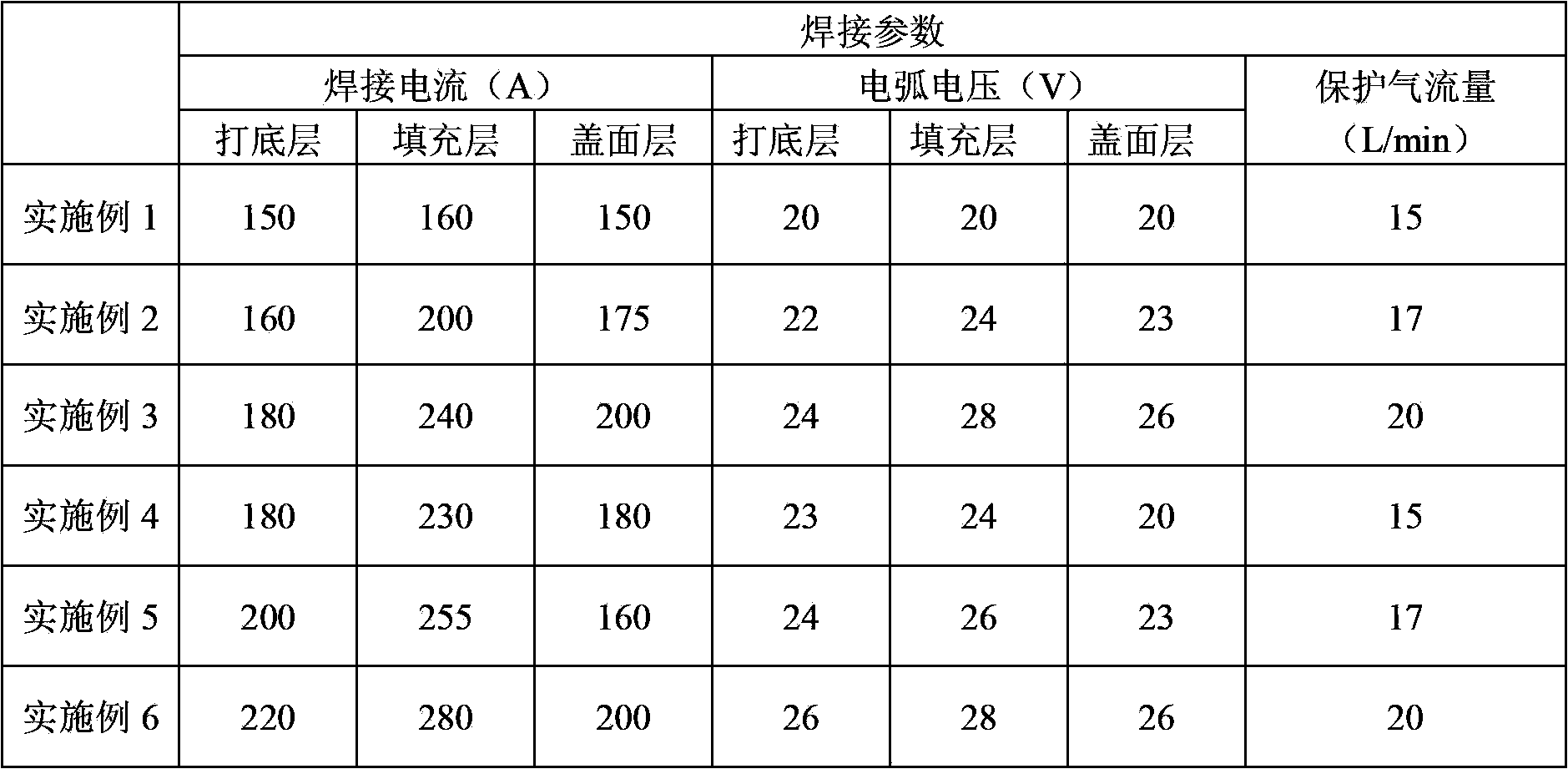

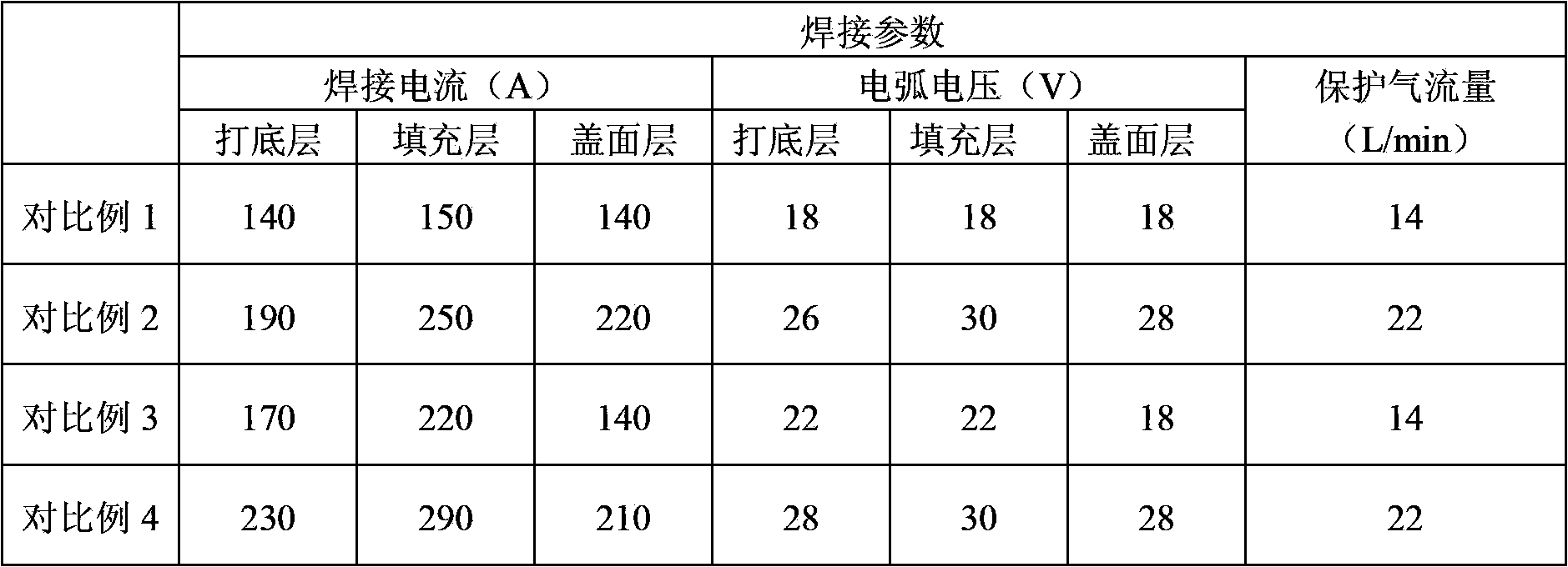

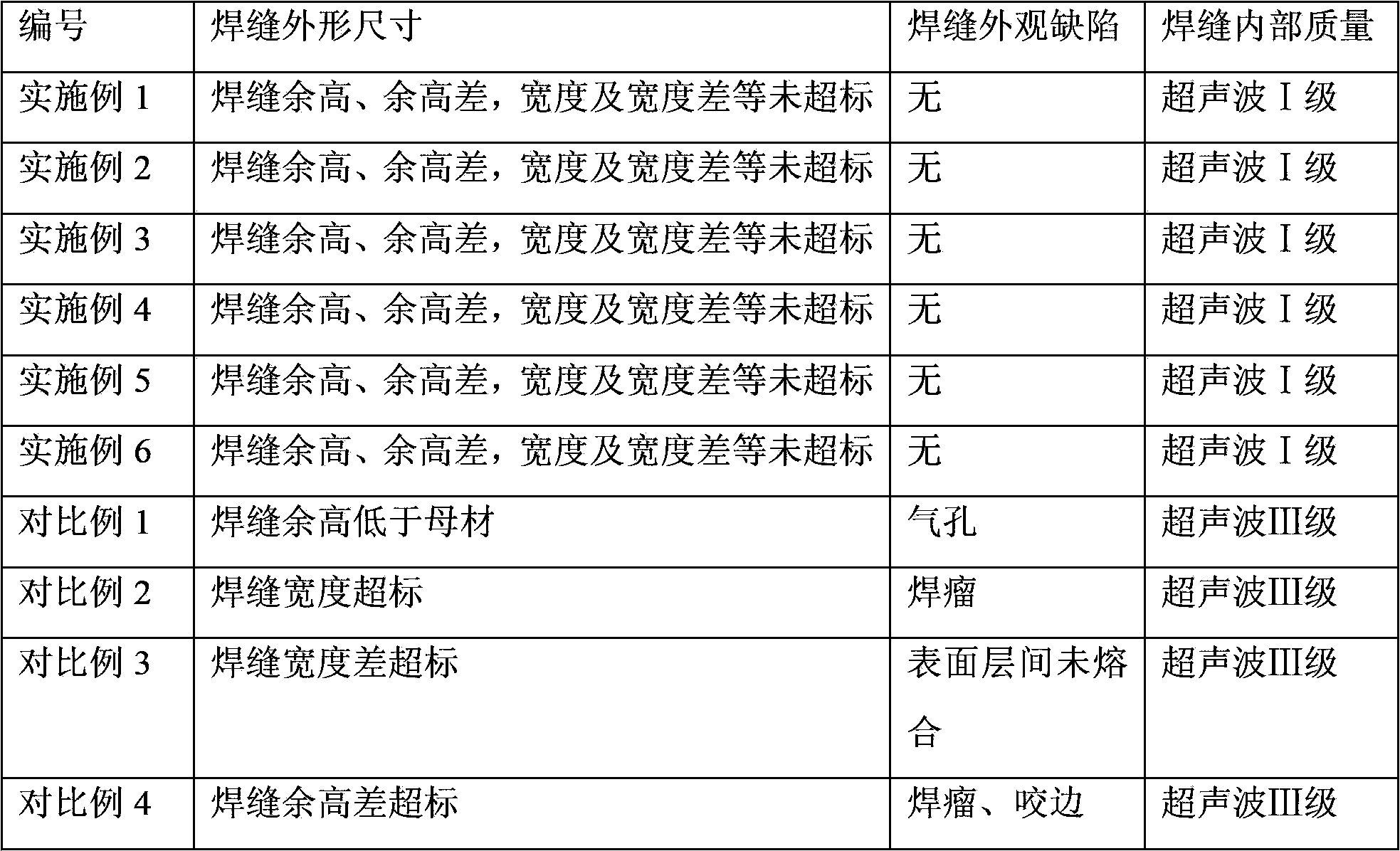

[0032] Use Φ1.6 solid core wire for CO 2 Gas shielded welding, the workpiece to be welded is a Q345B plate with a thickness of 40mm, the welding equipment is NB-630, and the welding wire grade is H08Mn2SiA. The welding process sequentially includes a welding primer layer, a welding filling layer and a welding capping layer. In Examples 1-3, the welding method of vertical welding is adopted, X-shaped grooves (double-sided gaps) are set up, the gaps reserved between the welding workpieces are 3mm, 4mm, and 5mm, and the number of welding layers is 6 layers (3 layers on one side) ); In the embodiment 4-6, the welding method of horizontal welding is adopted, and a K-shaped groove is set up. 14 (7 on one side) and 16 (8 on one side), the number of welding layers is 6 (3 on one side); see Table 1 for the selection of welding current, arc voltage and shielding gas flow during welding.

[0033] Table 1

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com