Welding tool for electric cabinets

A technology for welding tooling and electrical boxes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low failure maintenance rate and failure of electrical boxes to meet requirements, achieve high quality, and ensure welding efficiency. , to ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Those skilled in the art will be more aware of the above and other objects, advantages and features of the present invention according to the following detailed description of specific embodiments of the present invention in conjunction with the accompanying drawings.

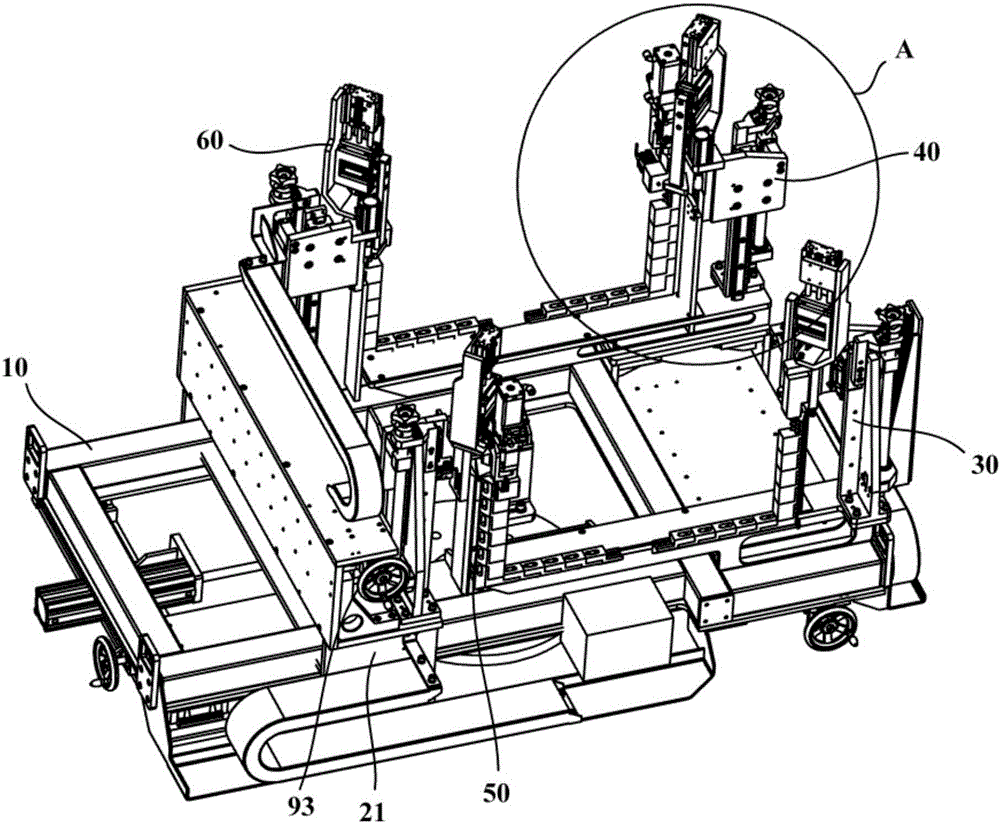

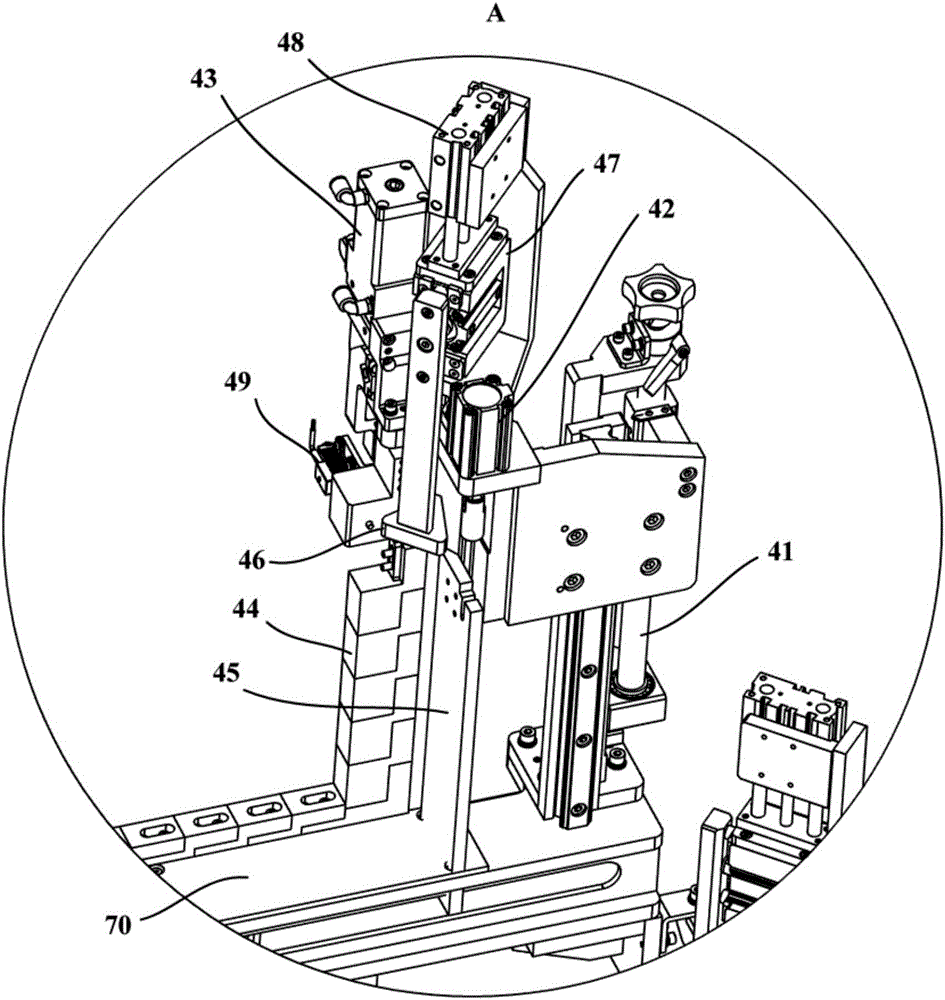

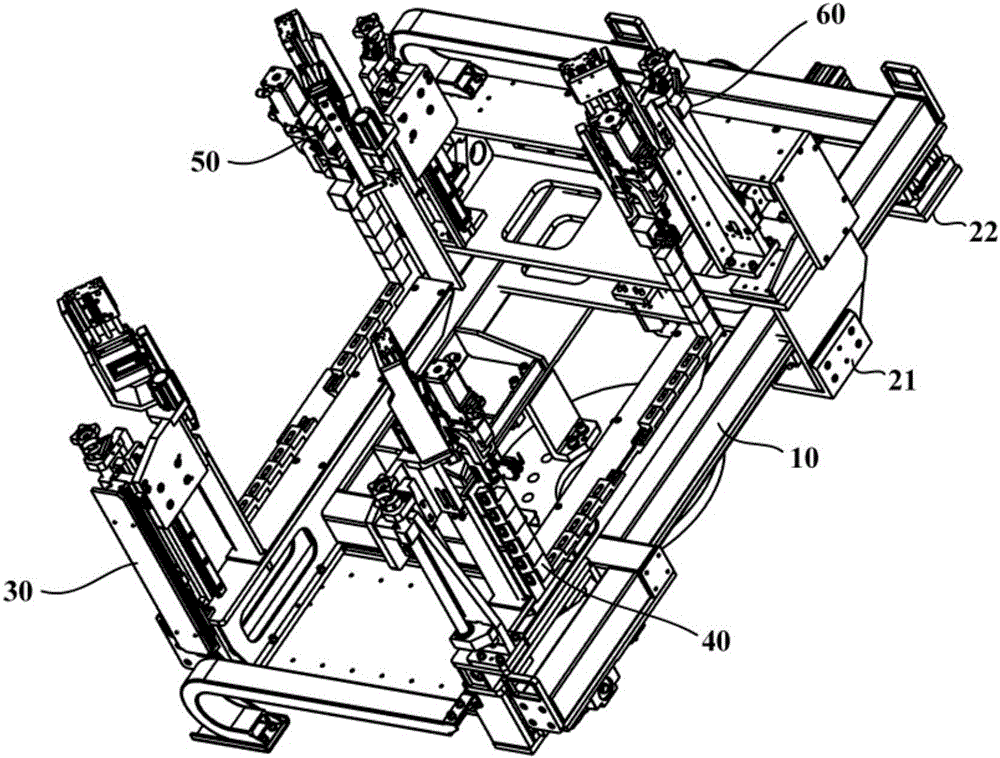

[0043] figure 1 is a schematic structural diagram of a welding tool 200 according to an embodiment of the present invention. Such as figure 1 shown and refer to Figure 2 to Figure 5 , the embodiment of the present invention provides a welding tool 200 for an electrical box 100, which may include a tool bracket 10, a first slide assembly 21, a first clamping device 30, a second clamping device 40, a third clamping device 50 and a fourth clamping device 60 .

[0044] In this embodiment, the tool bracket 10 is used to form the basis of the welding tool 200 and is used to be installed on a positioner so that the robot can weld the electrical box 100 clamped by the welding tool 200 . The tooling bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com