Three-way connector and laser electric-arc composite welding torch

A three-way connection and connector technology, used in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of difficult adjustment of synergy effect, difficult to guarantee welding efficiency and quality, etc., to achieve good synergy effect and ensure welding efficiency. and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to deeply understand the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

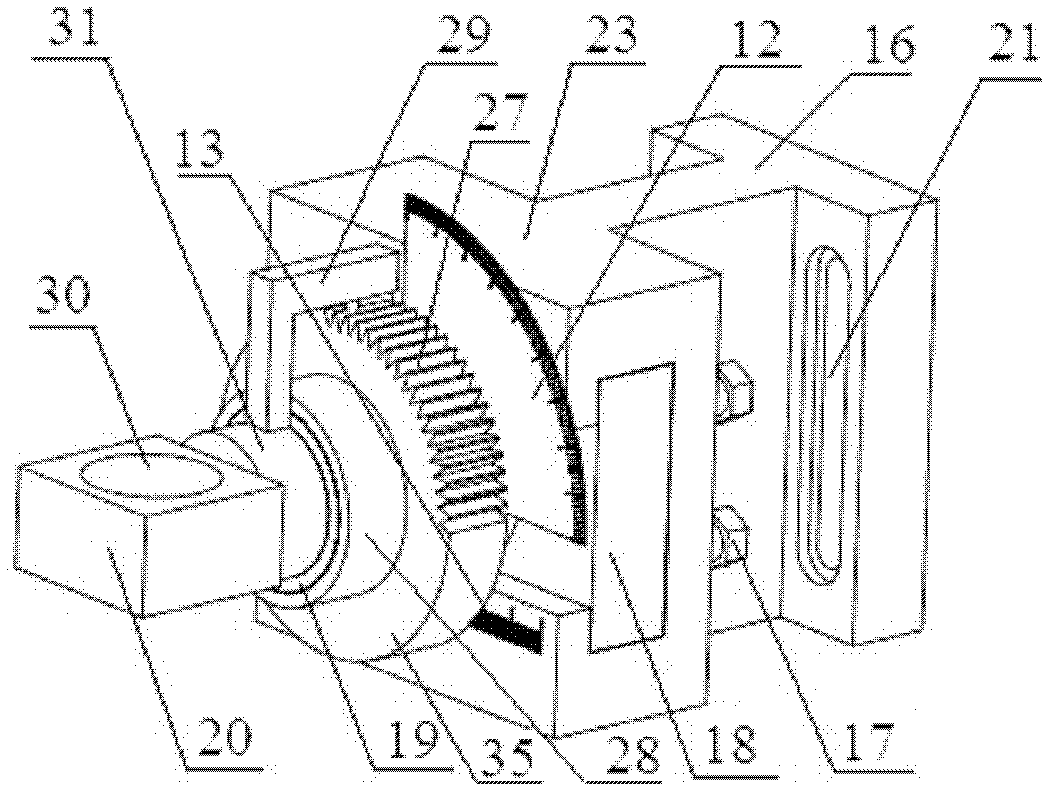

[0034] See attached figure 1 ~ attached Figure 4 , The three-way connector provided by the present invention includes an adjustment component I, an adjustment component II and an adjustment component III.

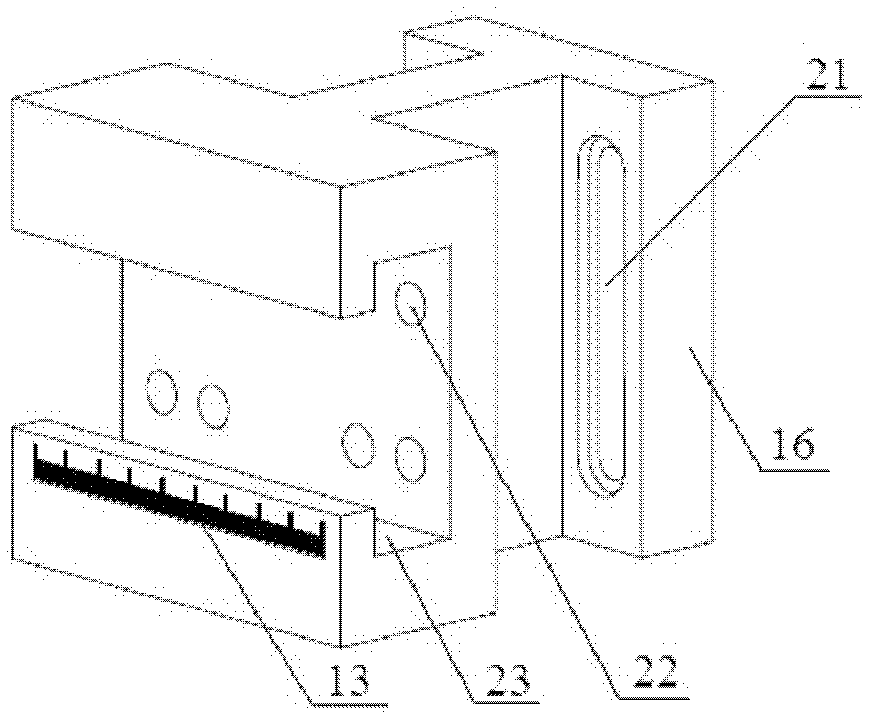

[0035] See attached figure 2 , the 1st adjusting member comprises longitudinal adjustment block 16 and transverse chute 23, and the both sides of longitudinal adjustment block 16 offer longitudinal adjustment groove 21 respectively, and transverse chute 23 is connected with longitudinal adjustment block 16, and longitudinal adjustment block 16 passes through longitudinal adjustment groove 21 external connections.

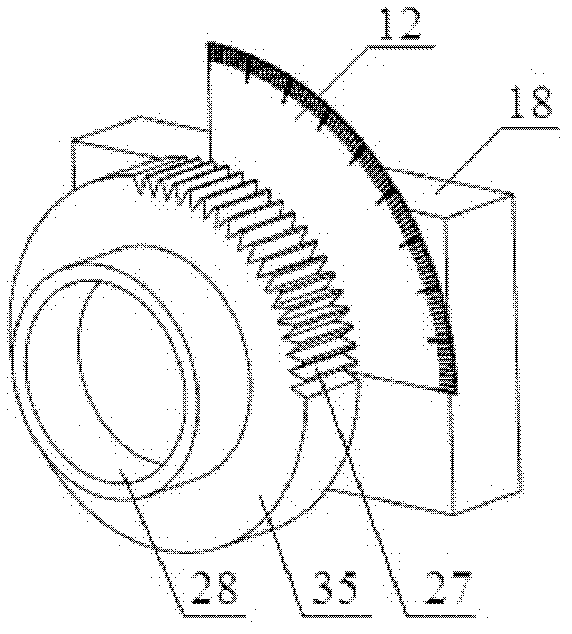

[0036] See attached image 3 , the II adjustment component includes a horizontal slider 18, a bearing hole 28 and a rotation adjustment ring 35, the bearing hole 28 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com