Ocean engineering module structure welding method based on VR technology

A marine engineering and modular structure technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor safety, inconvenient welding, and complicated welding environment, so as to reduce difficulty, improve welding efficiency, Get rid of highly dependent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

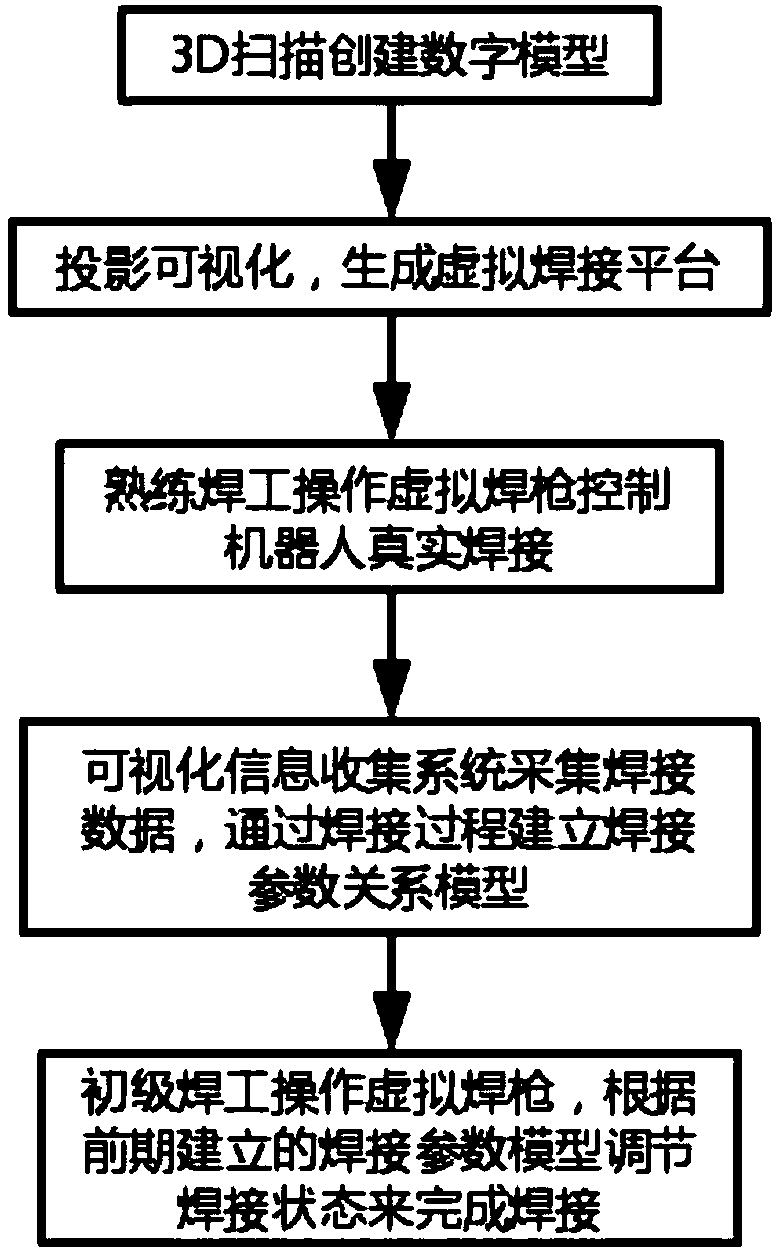

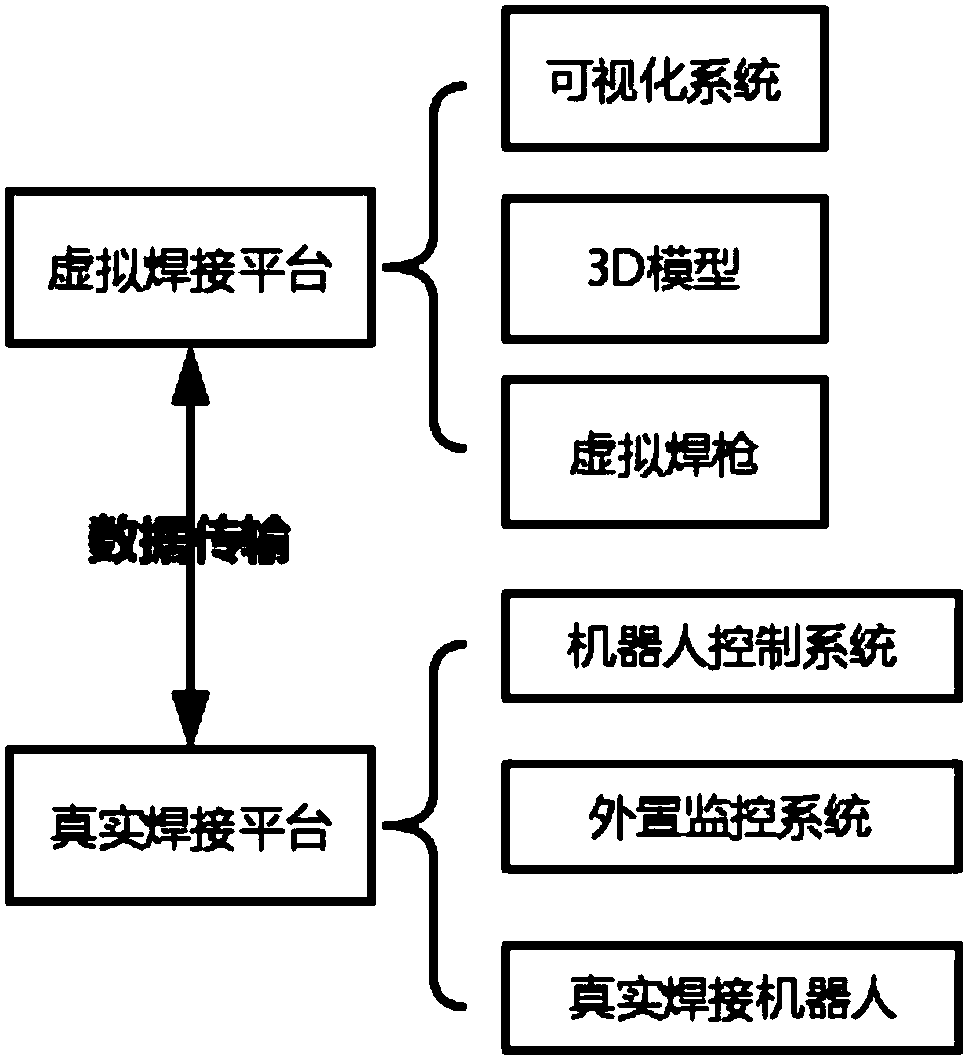

[0017] as attached figure 1 A kind of ocean engineering module structure welding method based on VR technology of the present invention shown, comprises the following steps:

[0018] (1) Create a digital model of the real welding workpiece through 3D scanning, and use the obtained digital model of the welding workpiece to process the workpiece model, so that the shape and size of the workpiece model are consistent with the real welding workpiece, thereby obtaining the 3D physical model of the workpiece;

[0019] (2) Use the camera to capture the real welding process, keep the 3D physical model consistent with the position of the real welding workpiece, and then use the projector to project the molten pool image captured by the camera on the surface of the 3D physical model in real time. Consistent, to visualize the molten pool image informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com