Semi-automatic welding machine for solar panels

A solar panel and semi-automatic welding technology, which is applied to welding equipment, auxiliary devices, tin feeding devices, etc., can solve the problems of affecting popularization and use, accounting for a large proportion of manufacturing costs, and low efficiency of solar panels, so as to ensure welding efficiency and Quality, guaranteed quality and accuracy, beneficial to the effect of welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

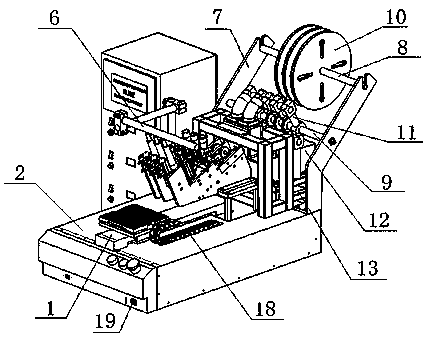

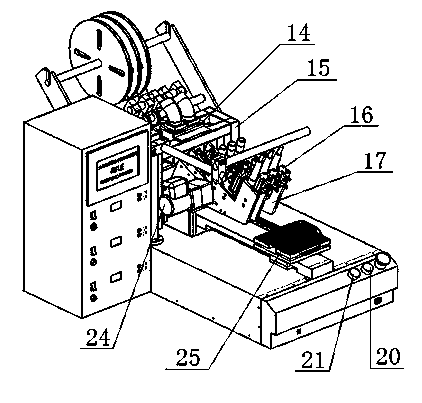

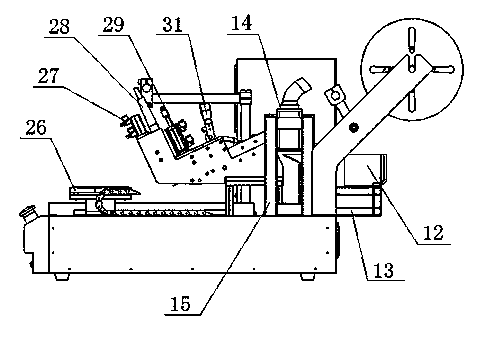

[0025] Such as Figure 1-Figure 13As shown, the solar panel semi-automatic welding machine includes a welding platform 1, a slide table 2, an electric control cabinet 3, a line rack 6, a tin tray support 7, a solder ribbon wheel 10, a solder ribbon straightening device 11, and a hanging solder box 12 , Hanging solder box bracket 13, drying device 14, drying device bracket 15, welding device 16, welding device main frame 17, drag chain 18, driving wheel stepping motor 24, lead screw stepping motor 39, ball screw 40 , workbench sliding assembly 41 and preheating device 50, electric control cabinet 3 is arranged on the outside of welding platform 1, slide table 2, line frame 6, tin plate support 7, hang solder box support 13, drying device support 15 and welding Device 16 is installed on welding platform 1 respectively, and one end of slide table 2 extends to the bottom of welding device 16, and workbench slide assembly 41 is installed on slide table 2, and support platform 53 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com