C70E cross beam constitution welding rollover table

A 1.C70E, turning table technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of mental fatigue and high physical strength of employees, and achieve obvious effects, concise structure and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

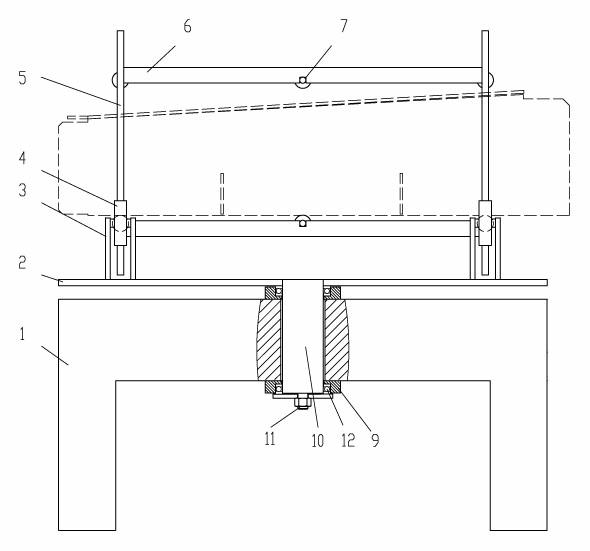

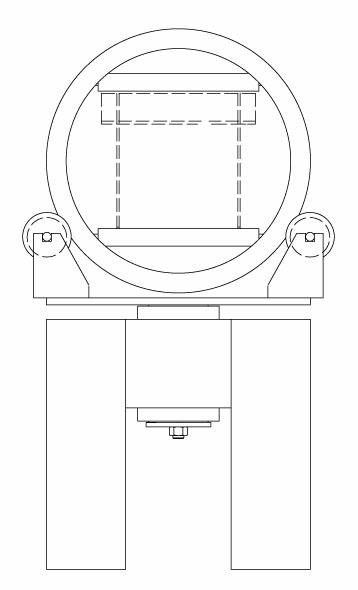

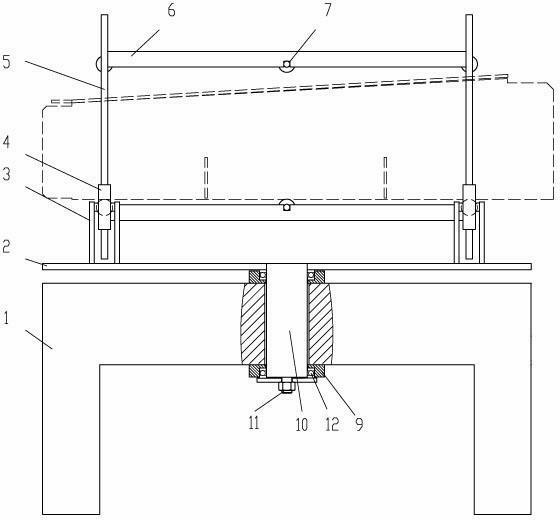

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] figure 1 or figure 2 As shown, the present invention includes a frame 1. The frame 1 supports a vertical shaft 10 that can rotate horizontally relative to the frame 1. A rotating tray 2 is fixed on the top of the vertical shaft 10. The upper surface of the rotating tray 2 supports a relatively rotating tray. 2 Rollers 4 that rotate vertically. The rollers 4 support a frame composed of C70E crossbeams that can be loaded with cards. Between them are connected by a roller shaft support 6, which is set to four, and the four roller shaft supports 6 are divided into two groups to support mutually parallel roller shafts 7 respectively.

[0017] The swivel joint between the vertical shaft 10 and the frame comprises bearings 12 .

[0018] The bearing 12 is a pressure bearing.

[0019] Through the 360-degree rotation of the rotating tray and the 360-degree vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com