Laying method of metal mesh false roof

A laying method and metal mesh technology, which are applied in mining equipment, earthwork drilling, temporary shielding, etc., can solve the problems of cumbersome steps, inability to guarantee safety, low operation efficiency, etc., so as to simplify the construction process and shorten the harvesting time. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

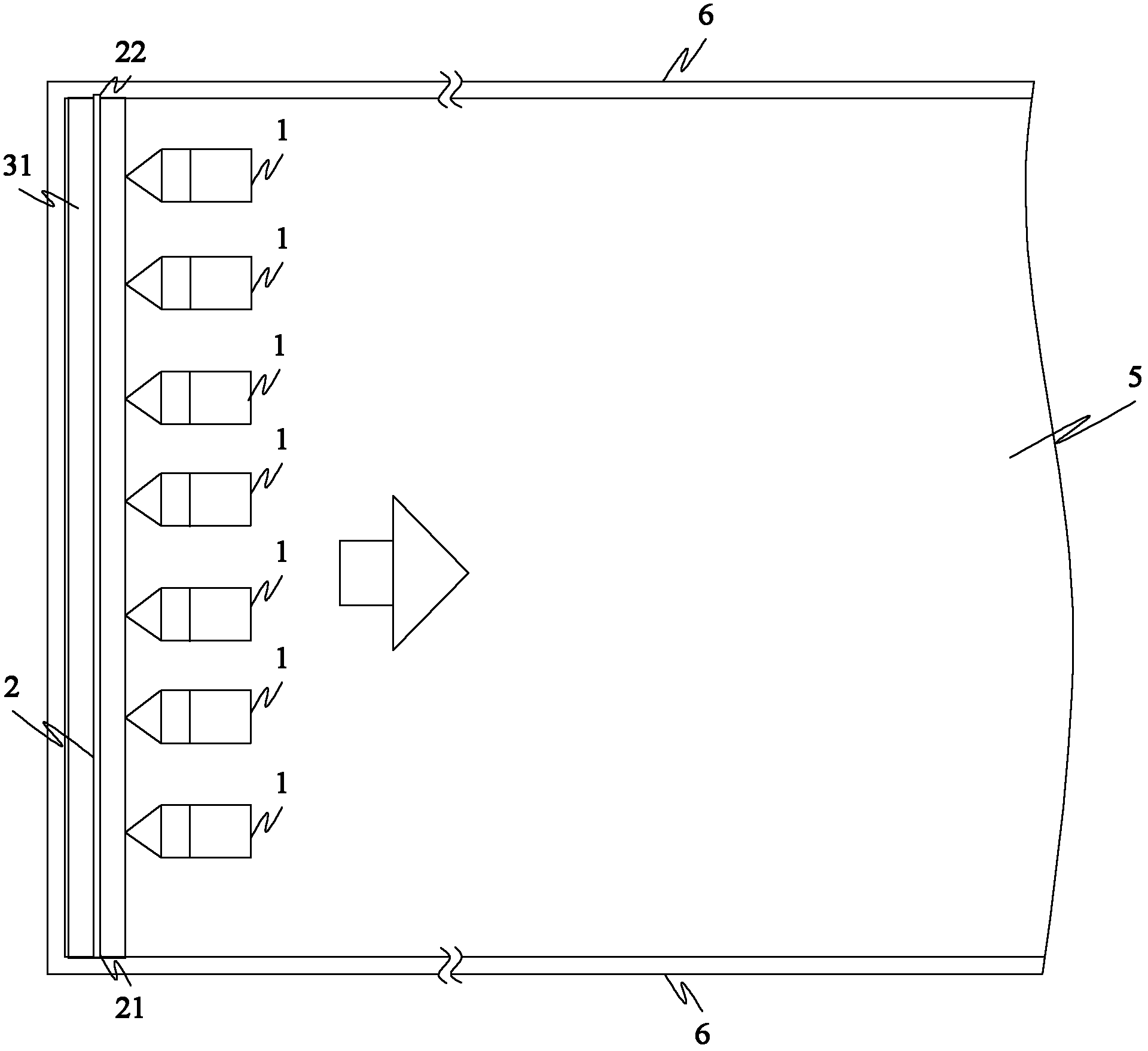

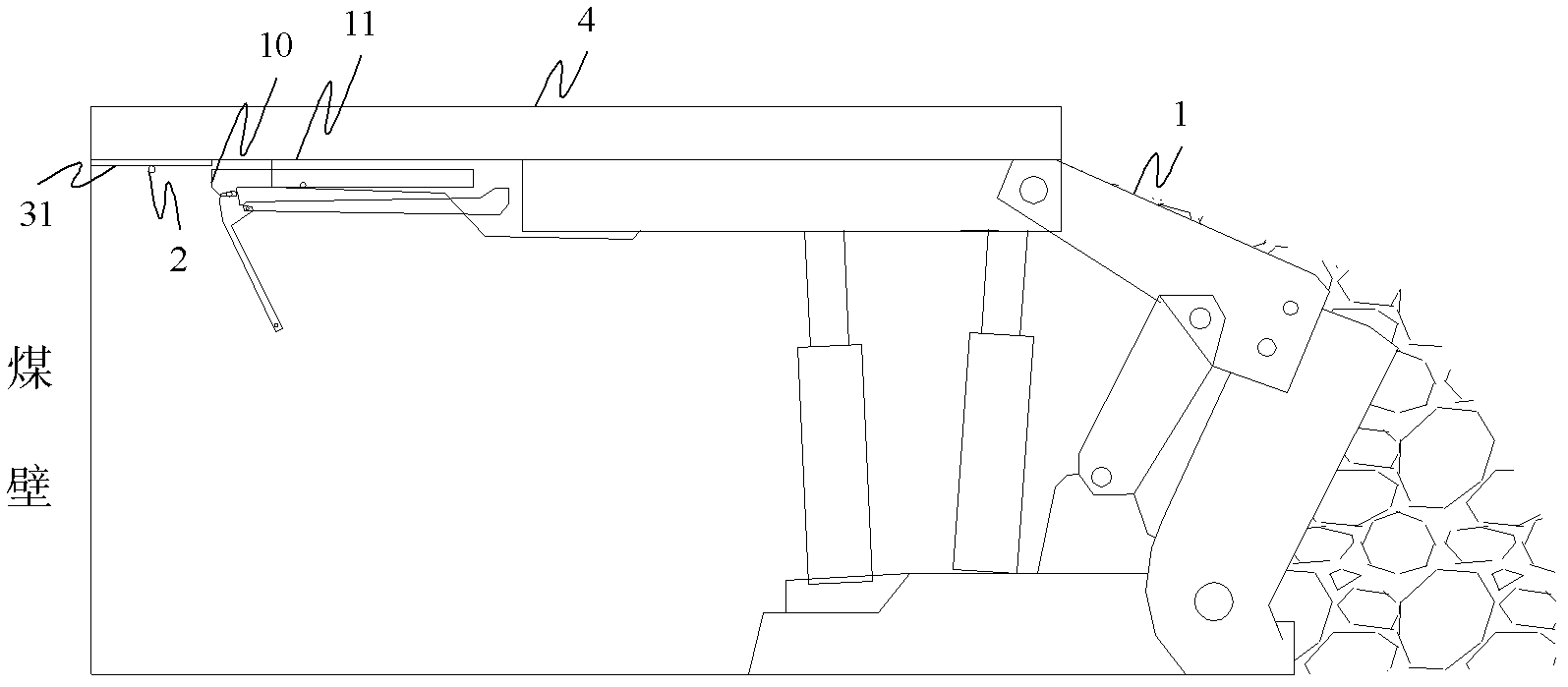

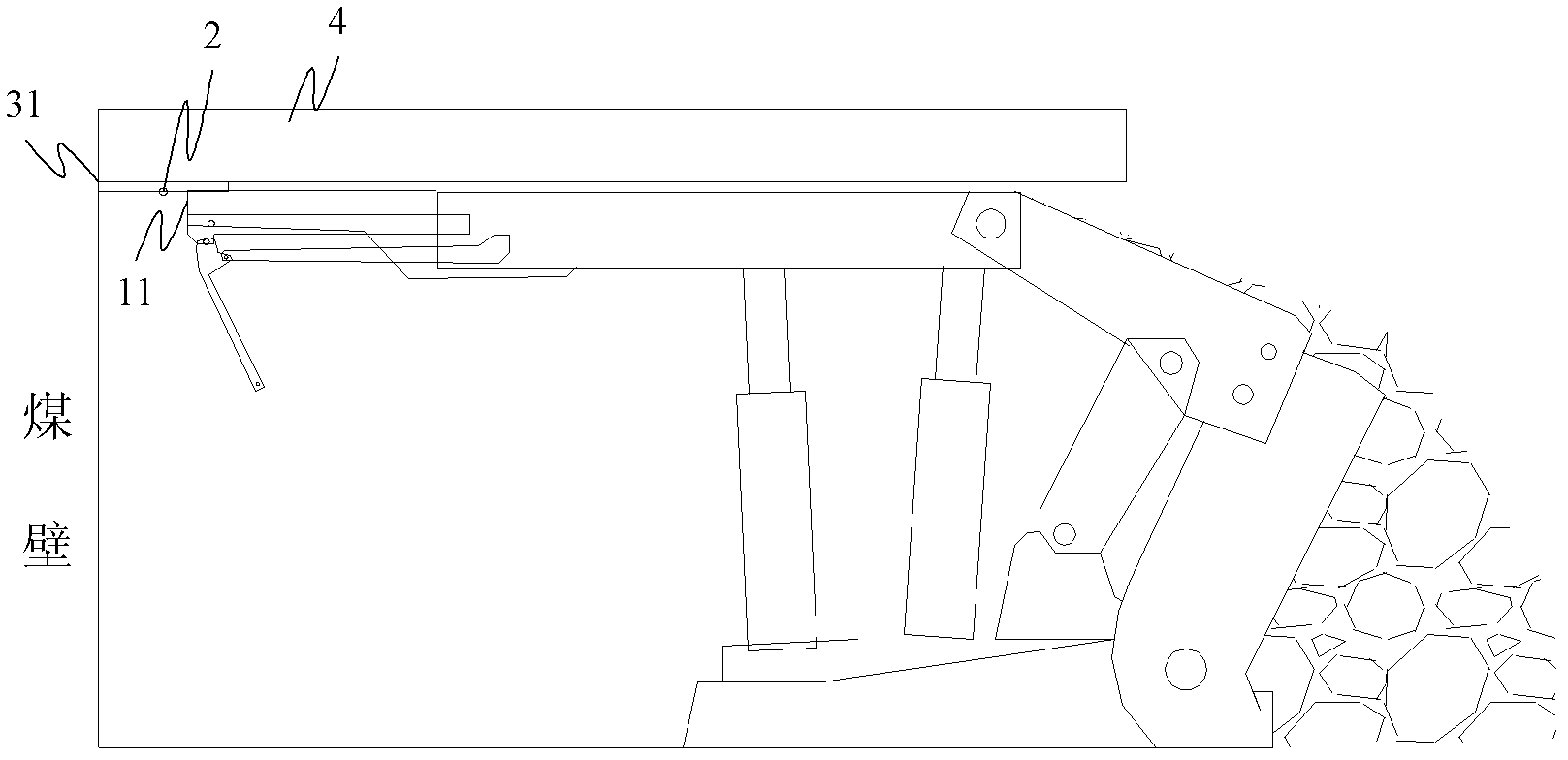

[0019] Such as Figure 1-4 As shown, the present invention provides a kind of laying method of metal mesh false roof, comprises the following steps:

[0020] Step 1, such as figure 1 , figure 2 As shown, the fully-mechanized mining face to be laid with protective metal mesh is basically the same as the current environment and facilities, that is, a plurality of hydraulic supports 1 are arranged at intervals along the width direction of the top wall of the fully-mechanized mining face 5, and the top of the hydraulic support 1 The upper end of the beam 11 supports the top wall 4 of the fully mechanized mining face, and a plurality of supporting beams (not shown in the figure) are arranged along the top walls of the roadway 6 on both sides of the fully mechanized mining face 5 . When laying the metal mesh, firstly, one end 21 of the steel wire rope 2 is fixed on one side of the fully mechanized mining face 5, and one end 21 of the steel wire rope 2 can be fixed on a support be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com