Construction method of asymmetric cable crane

A technology of cable cranes and construction methods, which is applied in the direction of suspension bridges, bridge parts, erection/assembly bridges, etc., which can solve the problems of long construction period, high safety risk, and large amount of steel used for steel towers, so as to reduce the difficulty of construction , improve structural stability, and ensure the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

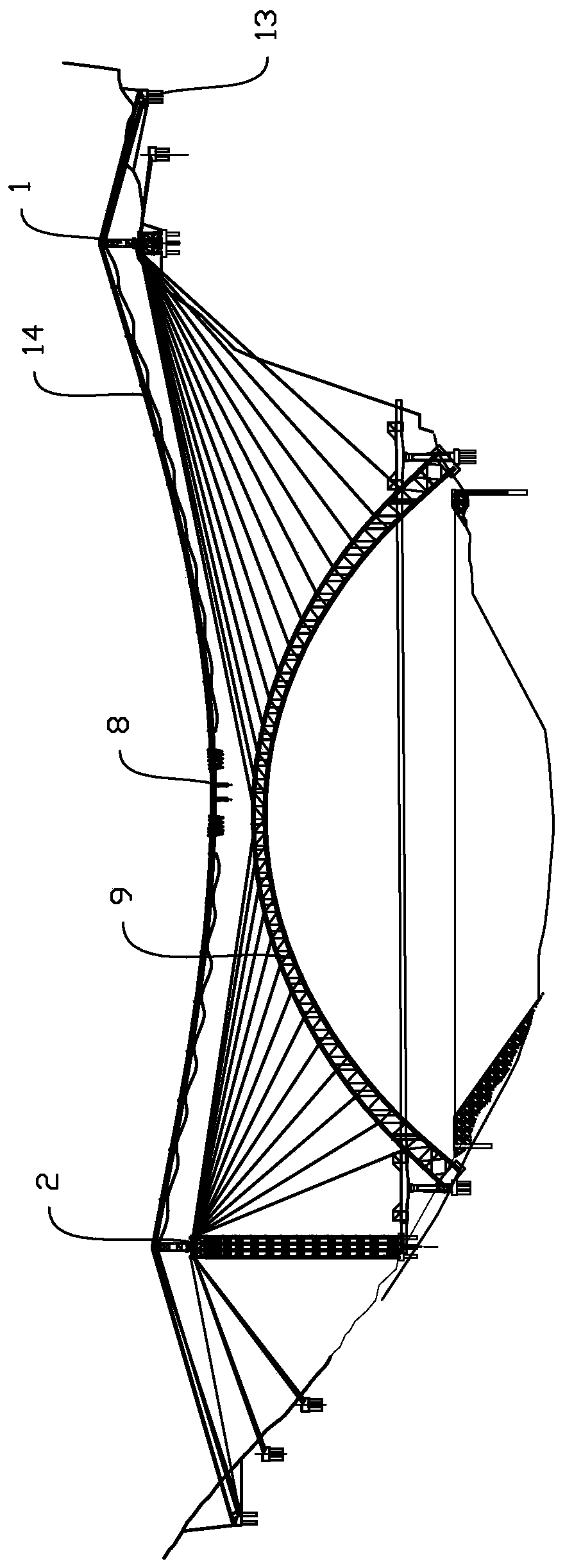

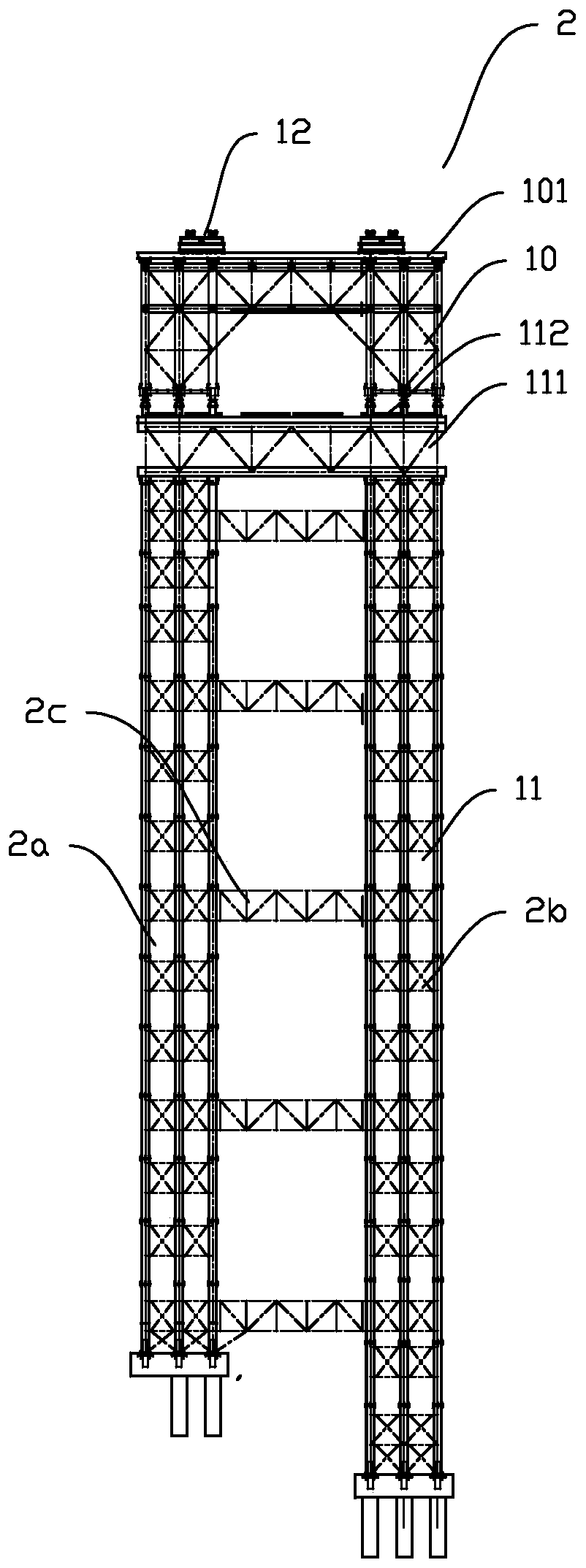

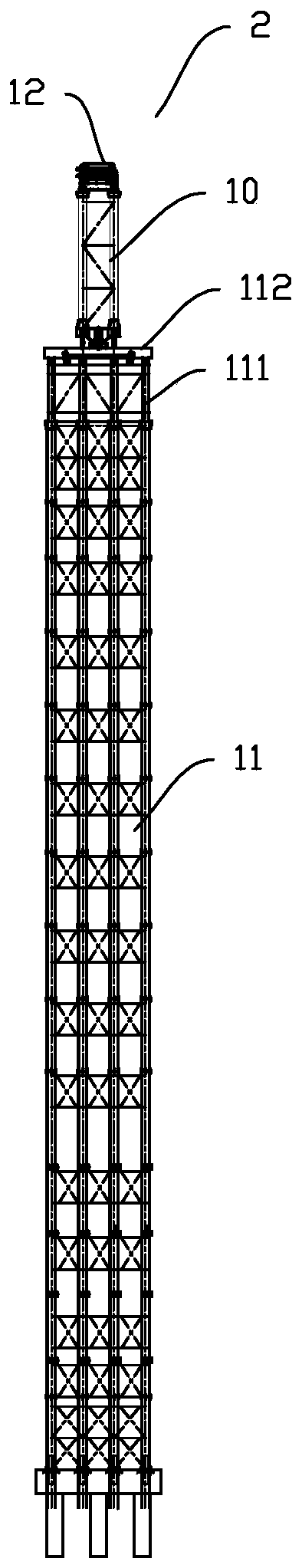

[0030] refer to Figure 1 to Figure 8 , the present invention is a kind of construction method of asymmetric cable crane, it is characterized in that, comprises the following steps:

[0031] A construction method of an asymmetrical cable crane, comprising the following steps:

[0032] 5) According to the height of the mountains on both sides of the valley, the side with high mountains is regarded as the side with large mileage, and the side with low mountains is regarded as the side with small mileage. Then the large-scale machinery and blasting equipment go up the mountain, use the blasting equipment to blast in layers and steps, then clean up and level the site, and set up slope protection;

[0033] 6) Excavate the pile foundation, construct the anchorage 13, construct the combined anchorage 131 on the mountain body on the large mileage side, and install the winch, set the conventional anchorage 13 on the mountain body on the small mileage side, set the winch, install the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com