Packingless fast vacuum prepressing dynamic consolidation method

A non-sealing and dynamic compaction technology, which is applied in the fields of soil protection, construction, and infrastructure engineering, can solve the problems of insufficient sealing, large loss of vacuum degree, and extended construction period, so as to save construction materials, Small loss of vacuum degree and good reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

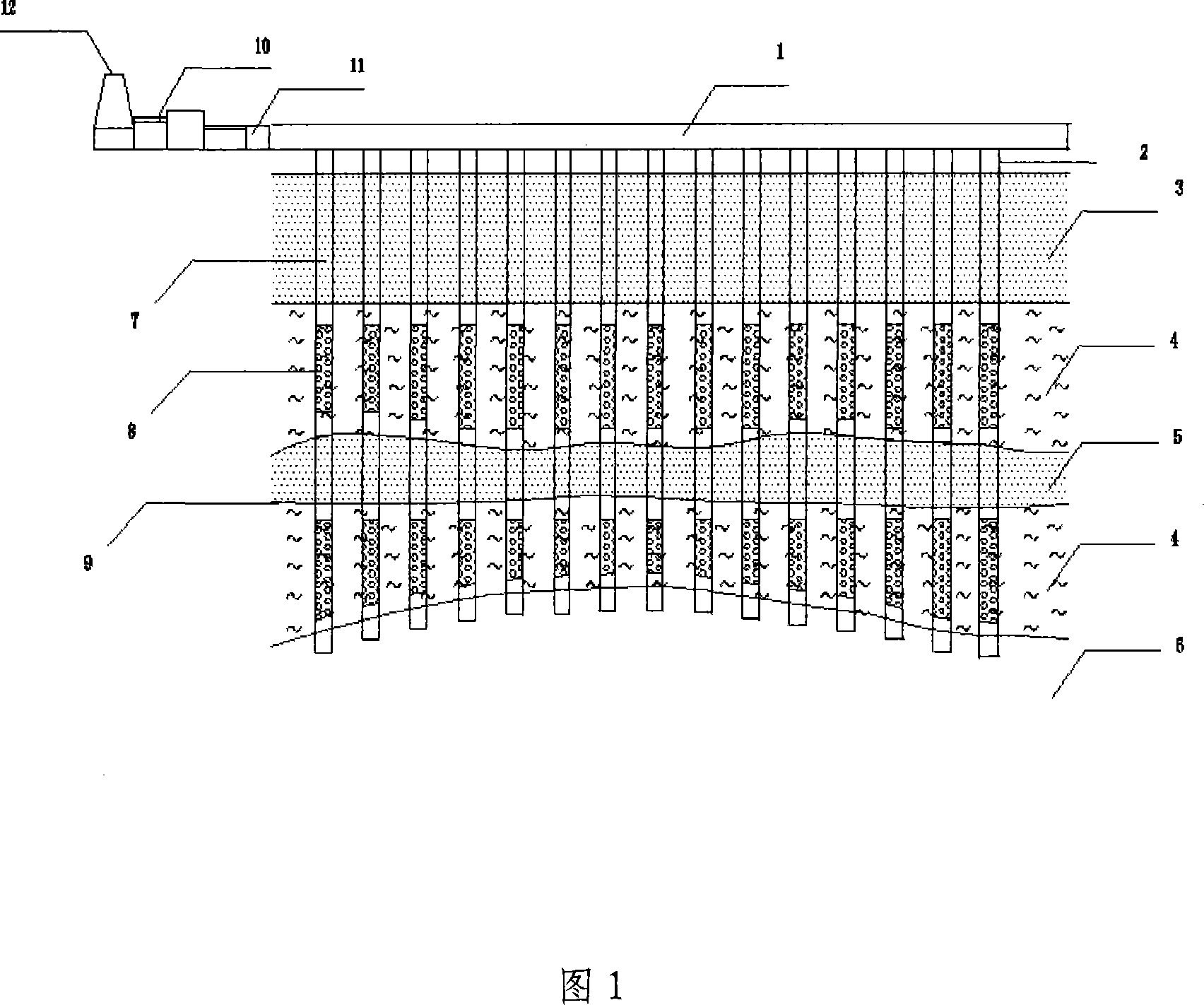

[0029] The object of the present invention is achieved in that the non-sealed fast vacuum preloading dynamic compaction method of the present invention comprises the following steps:

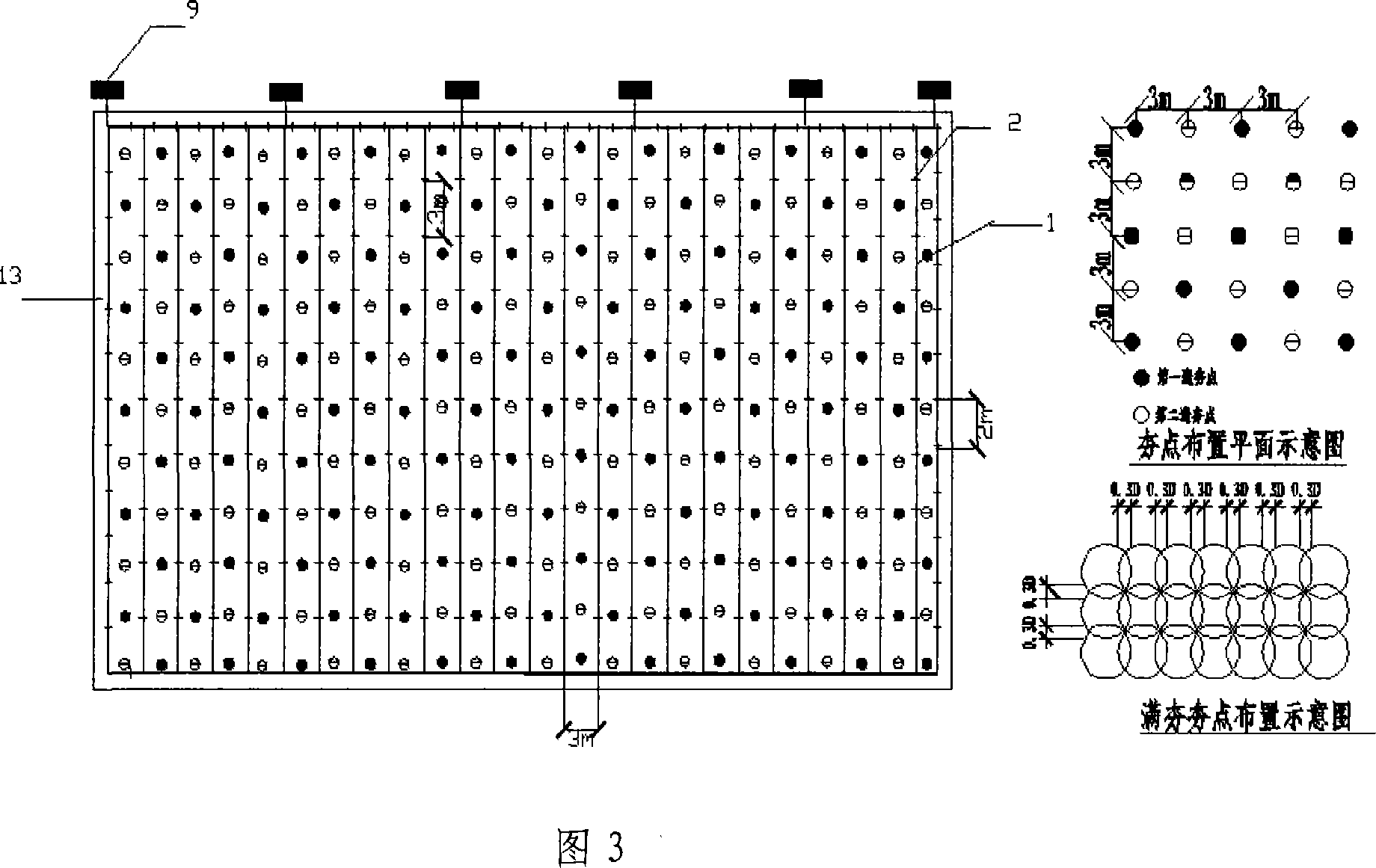

[0030] 1) Determine the stratum condition according to the site investigation data, and arrange the filter holes according to the stratum condition;

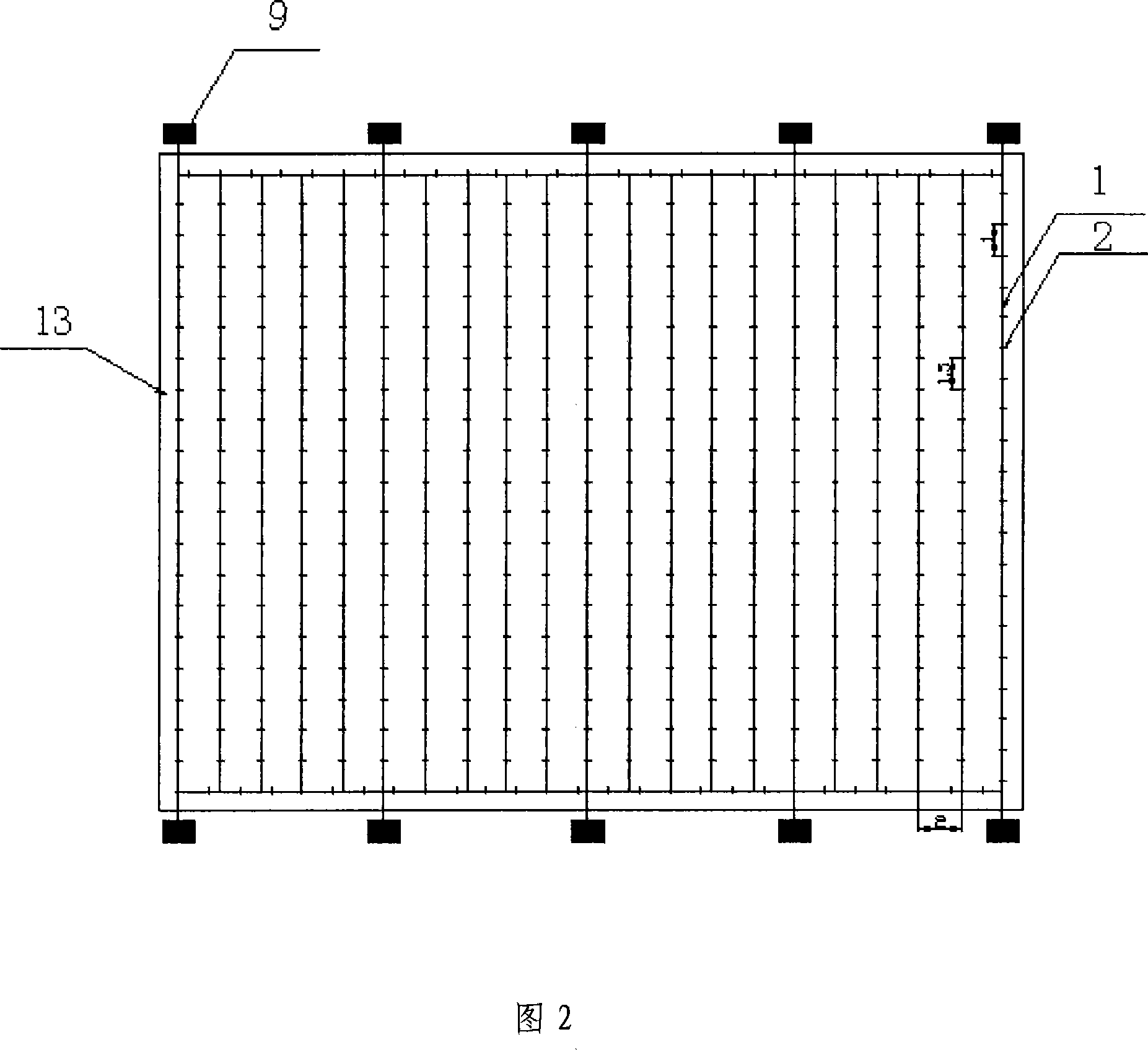

[0031] 2) Insert the filter tube 2 into the ground according to the designed depth, and the upper end of the filter tube 2 exposed to the soil layer is directly connected to the main pipe 1, and the main pipe 1 is directly connected to the vacuuming equipment 12 for vacuum preloading construction; the vacuuming equipment is a vacuum pump.

[0032] 3) Evacuate with vacuum equipment 12, under the action of internal and external pressure difference, the water in the weak cohesive soil layer is sucked into the filter pipe 2, rises along the filter pipe, and is discharged through the main pipe 1 until the design requirements are met.

[0033] After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com