Sieve tube drilling process for outburst coal seam section in underground coal mine

A technology for protruding coal seams and processes, applied in the direction of drill pipes, drill pipes, casings, etc., can solve problems such as gas overrun accidents, low safety, and low efficiency, and achieve the goals of improving safety protection, saving construction materials, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

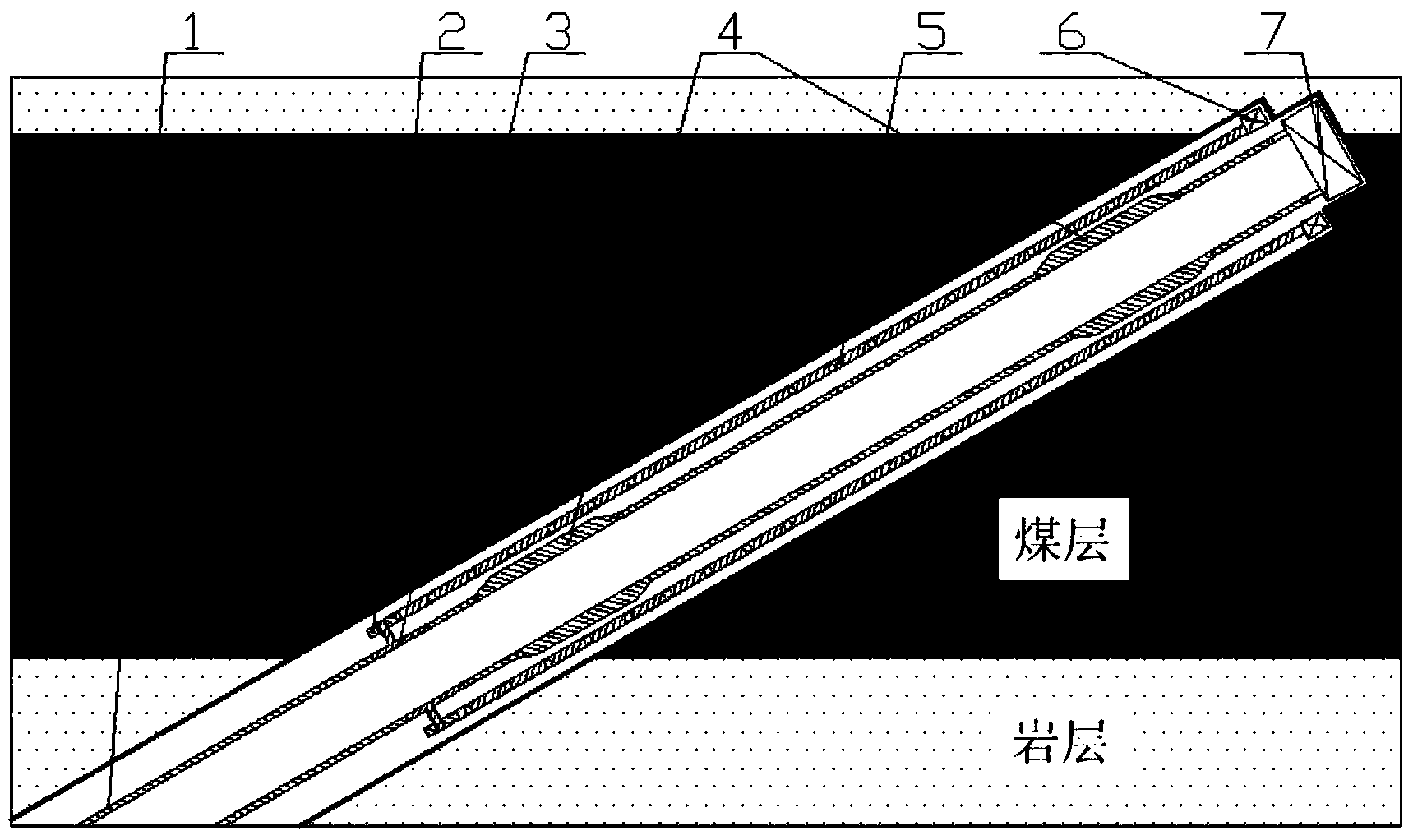

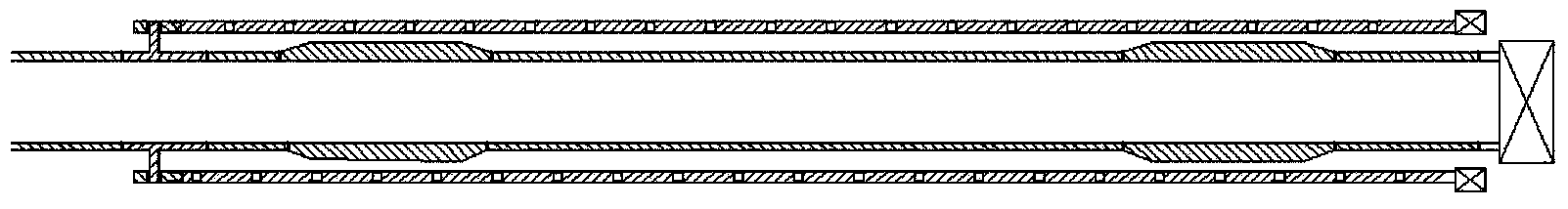

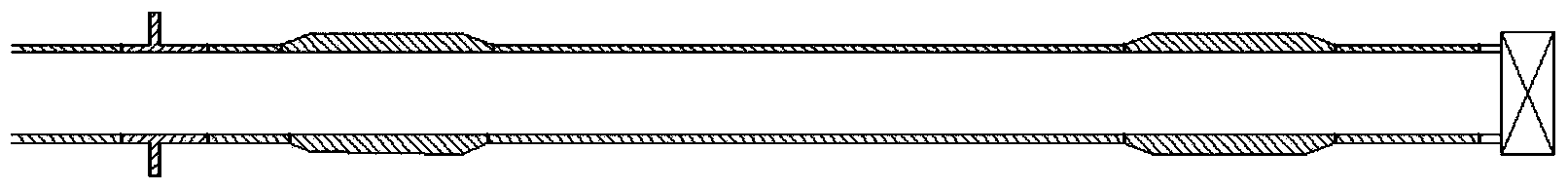

[0030] Such as figure 1 As shown, the coal mine underground outburst coal seam segment screen pipe drilling process of the present invention comprises the following steps:

[0031] Preparatory step: calculating the length of the section crossing the outburst coal seam, optionally, the length is calculated according to the required drilling depth, rock layer thickness, inclination angle, and azimuth angle of the roof or floor;

[0032] Hole opening step: After drilling to the depth of the hole through the drilling rig, install the orifice pipe and seal the hole for fixation;

[0033] Simultaneous drilling steps: After drilling to the designed hole dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com