Large water tower cylinder hydraulic slip-form vertical-transportation system and method

A vertical transportation and water tower technology, applied in the field of vertical transportation systems, can solve problems such as difficult operation, high safety hazards, large construction materials, etc., and achieve the effect of ensuring personal safety, ensuring safety and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention.

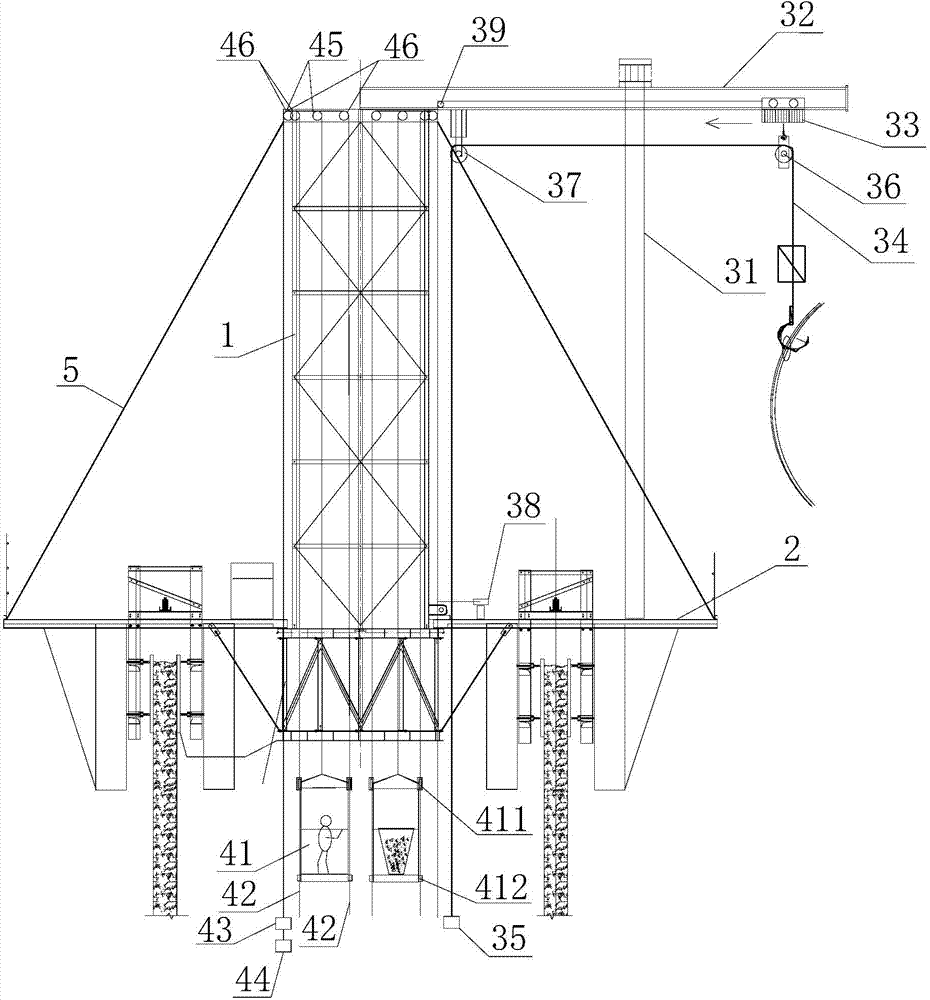

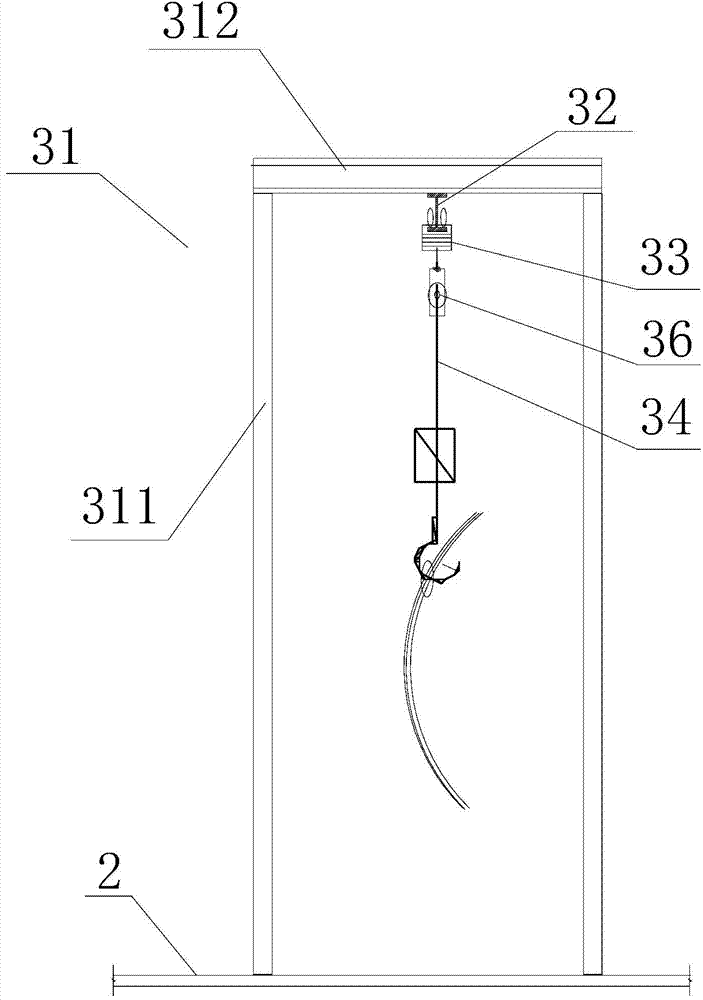

[0030] like figure 1 and figure 2 As shown, the hydraulic sliding form vertical transport system for large water tower body of the present invention includes a lifting derrick 1 and a working platform 2, and the lifting derrick 1 is fixed on the working platform 2, and also includes a lifting device outside the cylinder, a cylinder The external lifting device is used to lift heavy objects from the outside of the water tower cylinder body, such as steel and other objects; the external lifting device includes a support frame 31, a rigid slideway 32, an electric hoist 33, a load-bearing rope 34 and a driving device A35, The support frame 31 is fixed on the working platform 2, the rigid slideway 32 is horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com