Patents

Literature

30results about How to "Improve surface wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

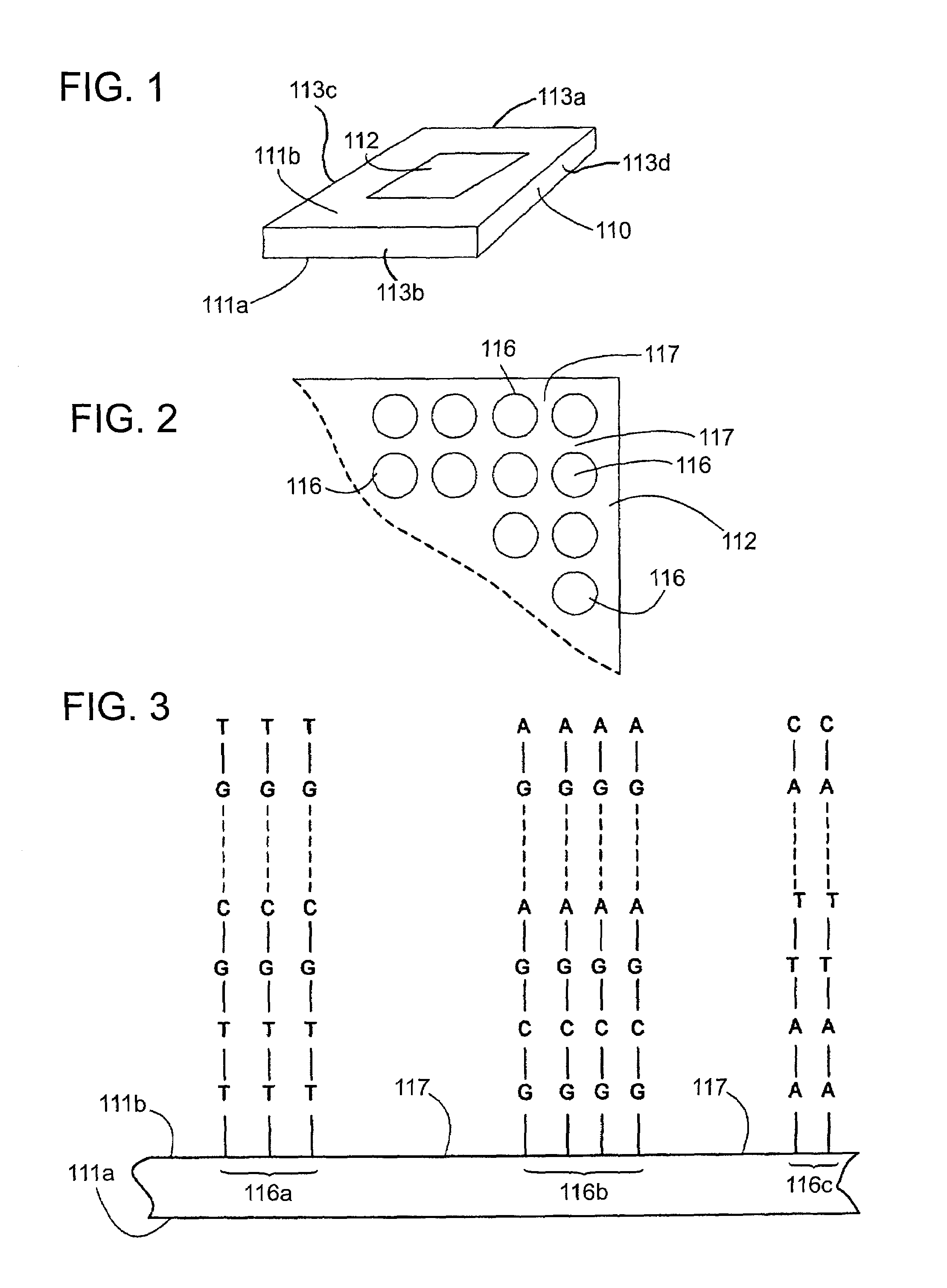

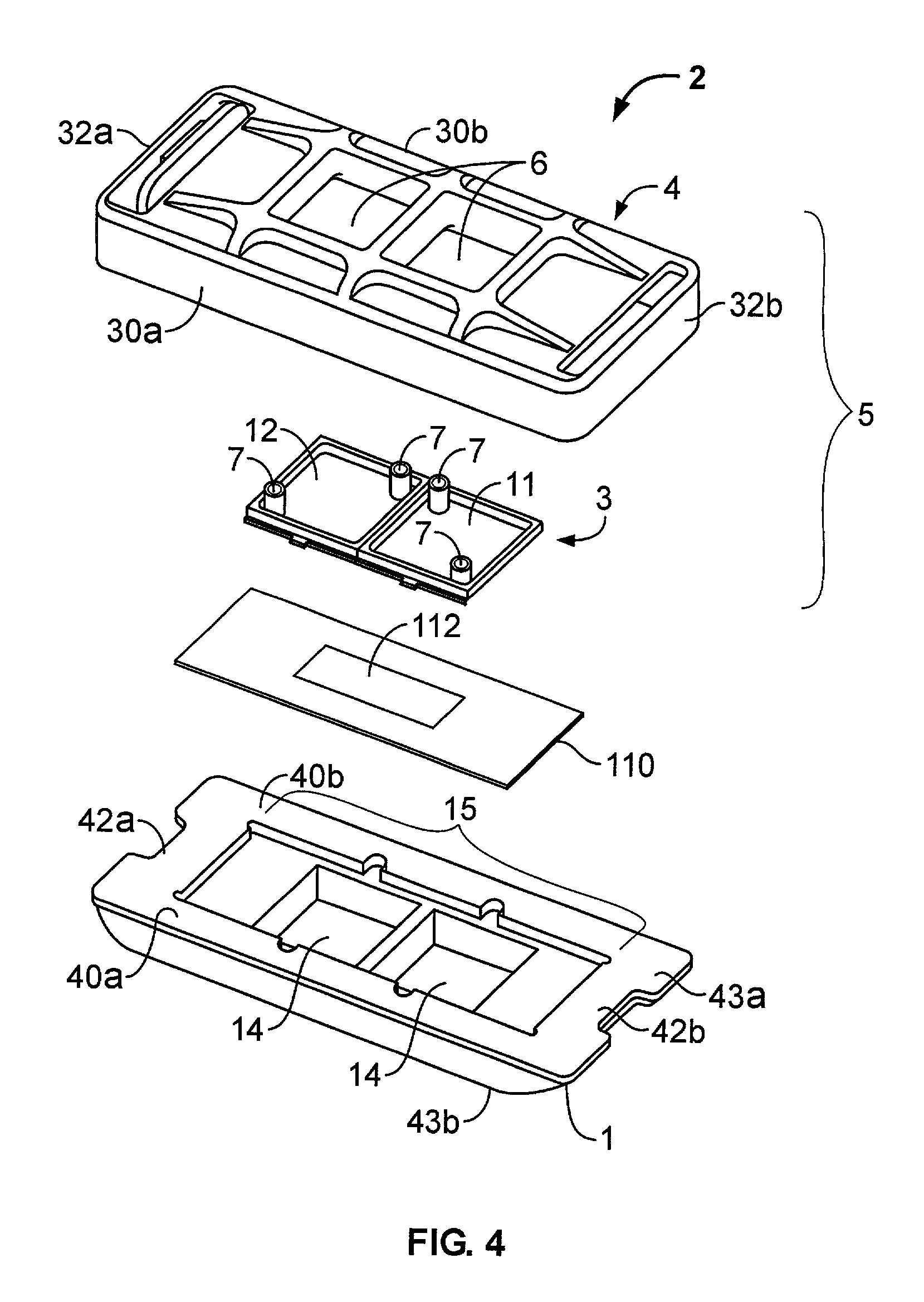

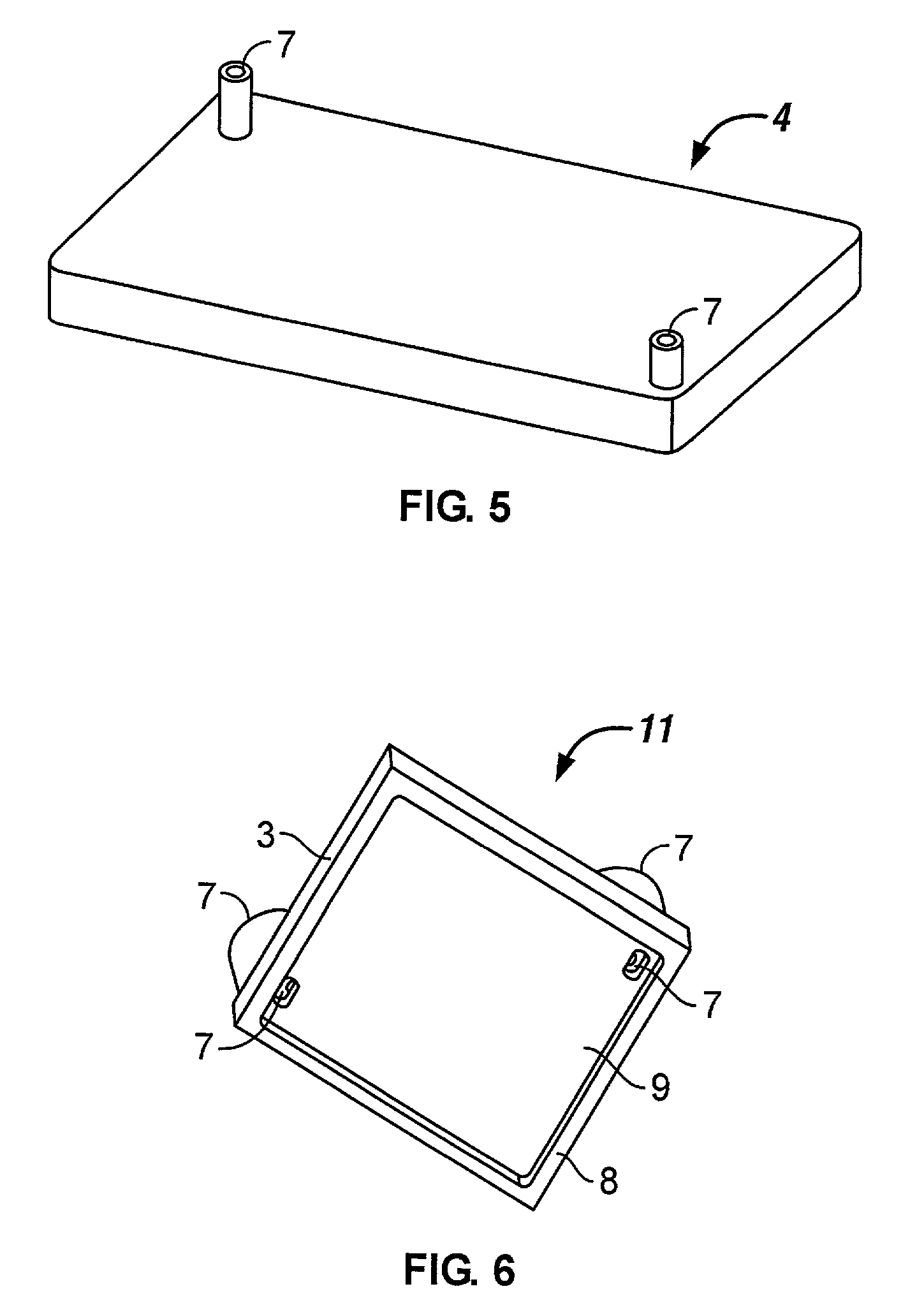

Array assay devices and methods of using the same

InactiveUS7220573B2Reduce surface tensionImprove surface wettingBioreactor/fermenter combinationsPeptide librariesBiology

Array assay devices and methods for using the same in array based assays are provided. The subject devices are characterized by having a base dimensioned to hold a substrate having at least one array, a cover dimensioned to cover the substrate and a snap-fit for holding the cover and the base together to enclose a space between the base and the cover. The subject invention also includes methods for performing an array assay. In the subject methods, a subject device is provided and a substrate having at least one array is positioned on the base. The snap-fit is engaged to hold the cover and the base together to enclose a space between the base and the cover. Next, a sample is contacted with the at least one array and an array assay is performed. The subject invention also includes kits which include the subject devices.

Owner:AGILENT TECH INC

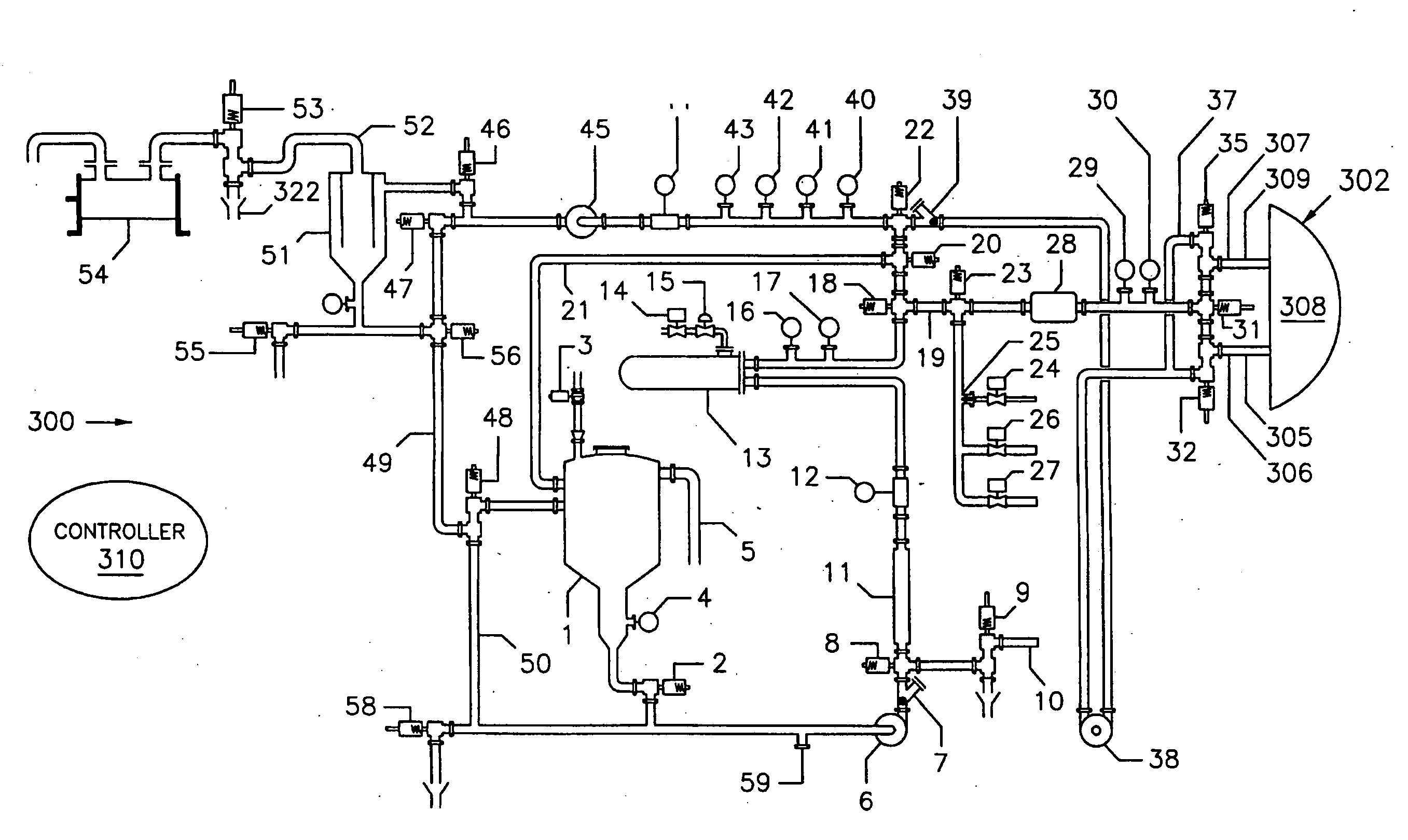

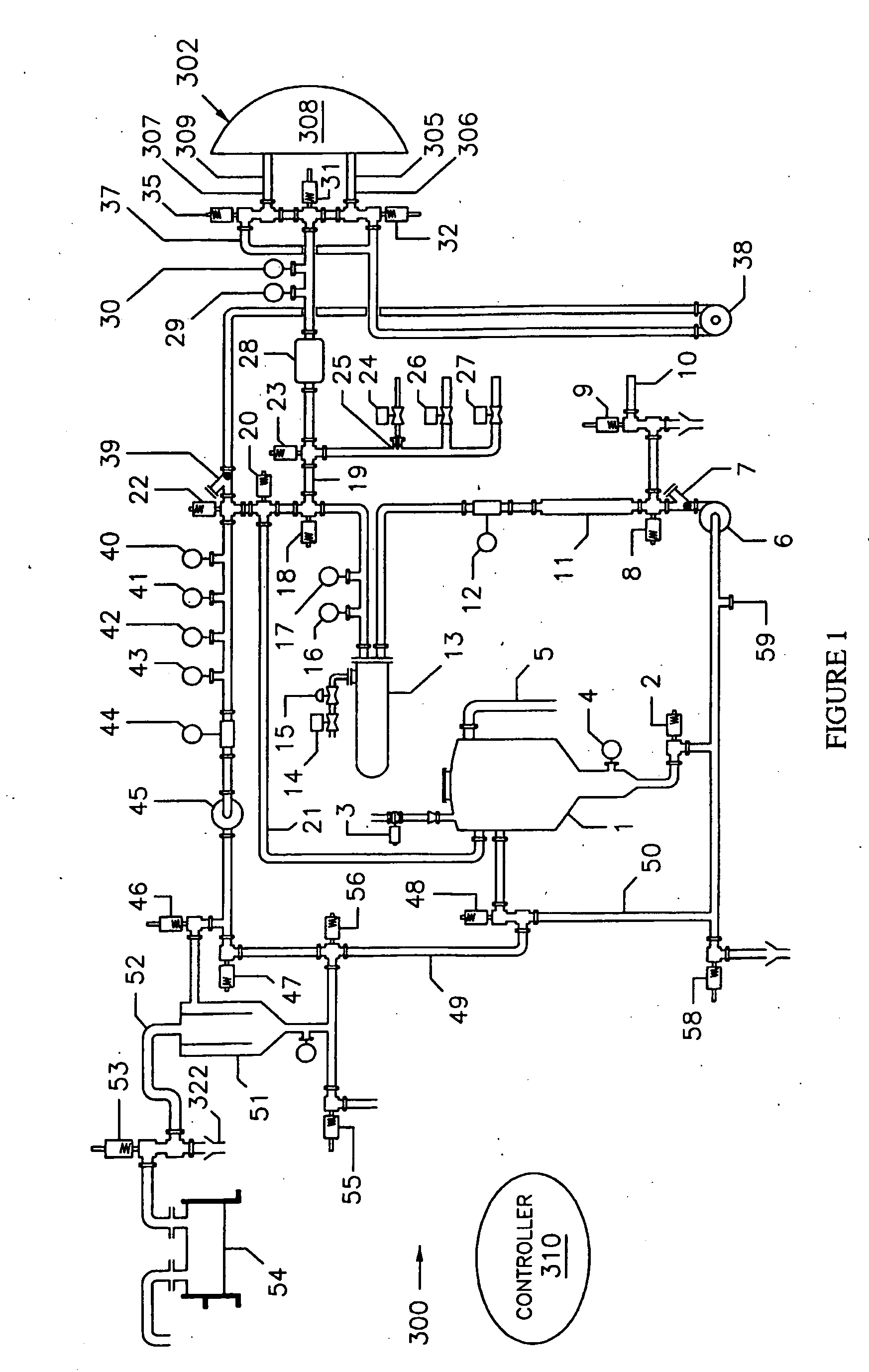

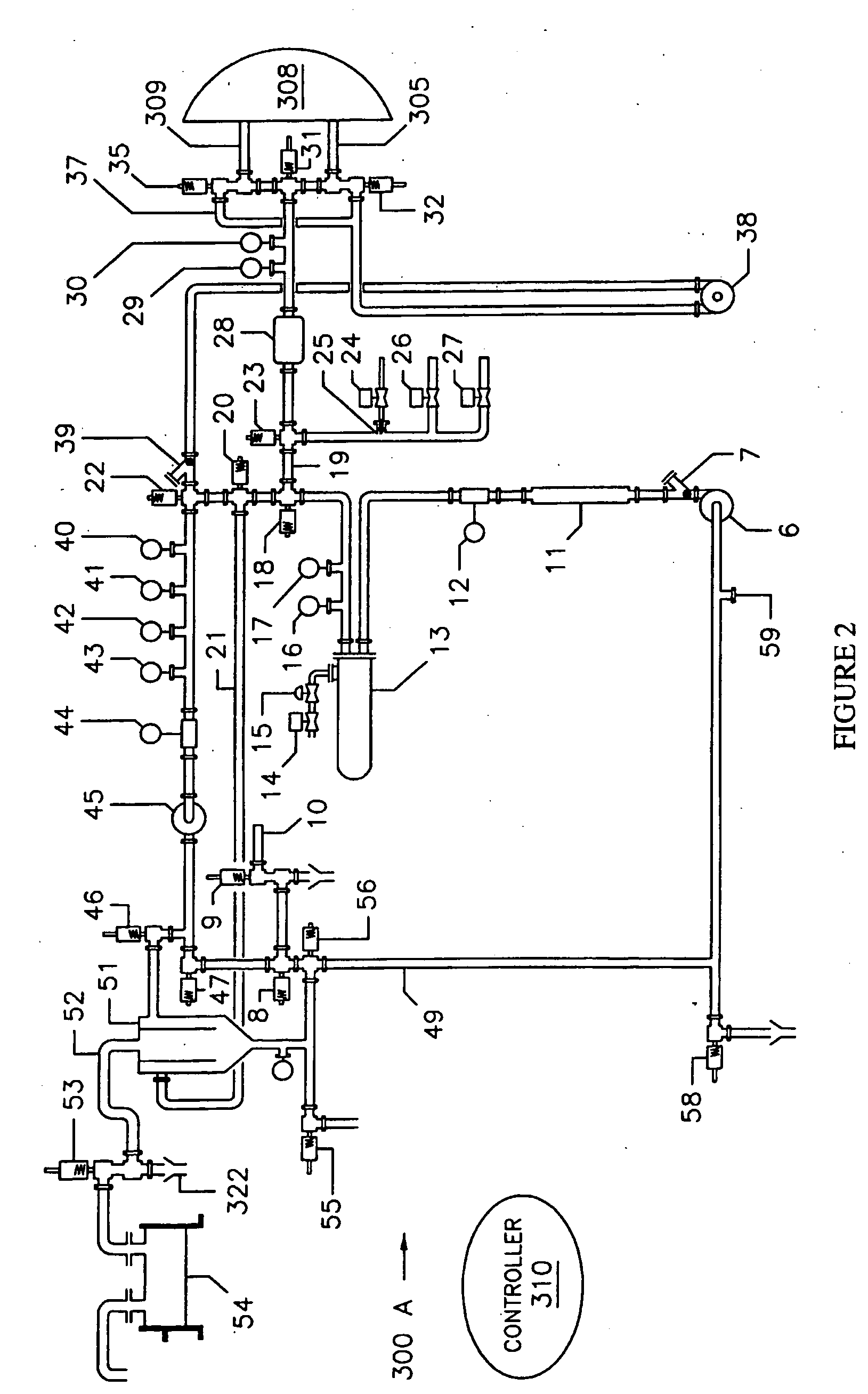

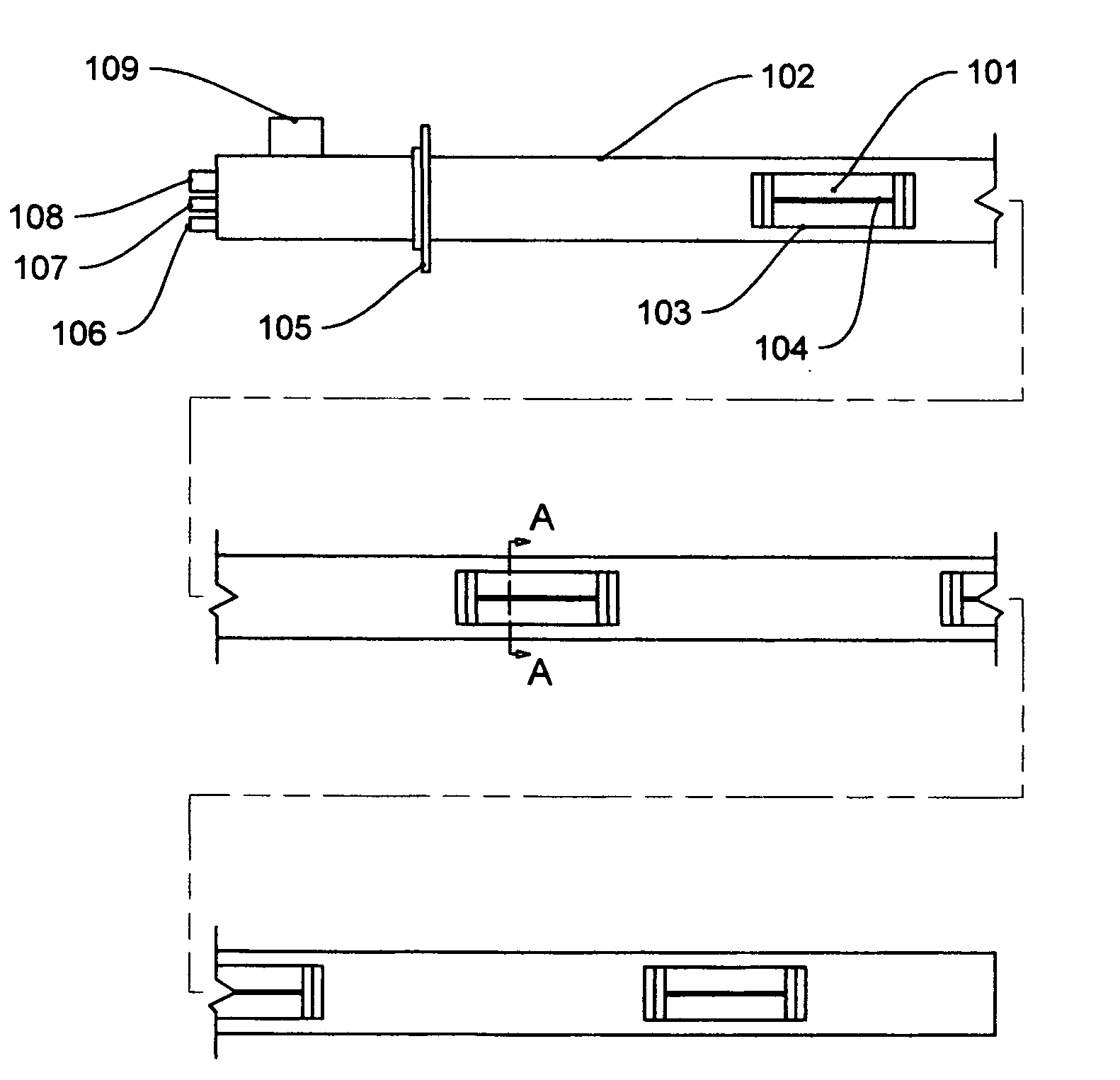

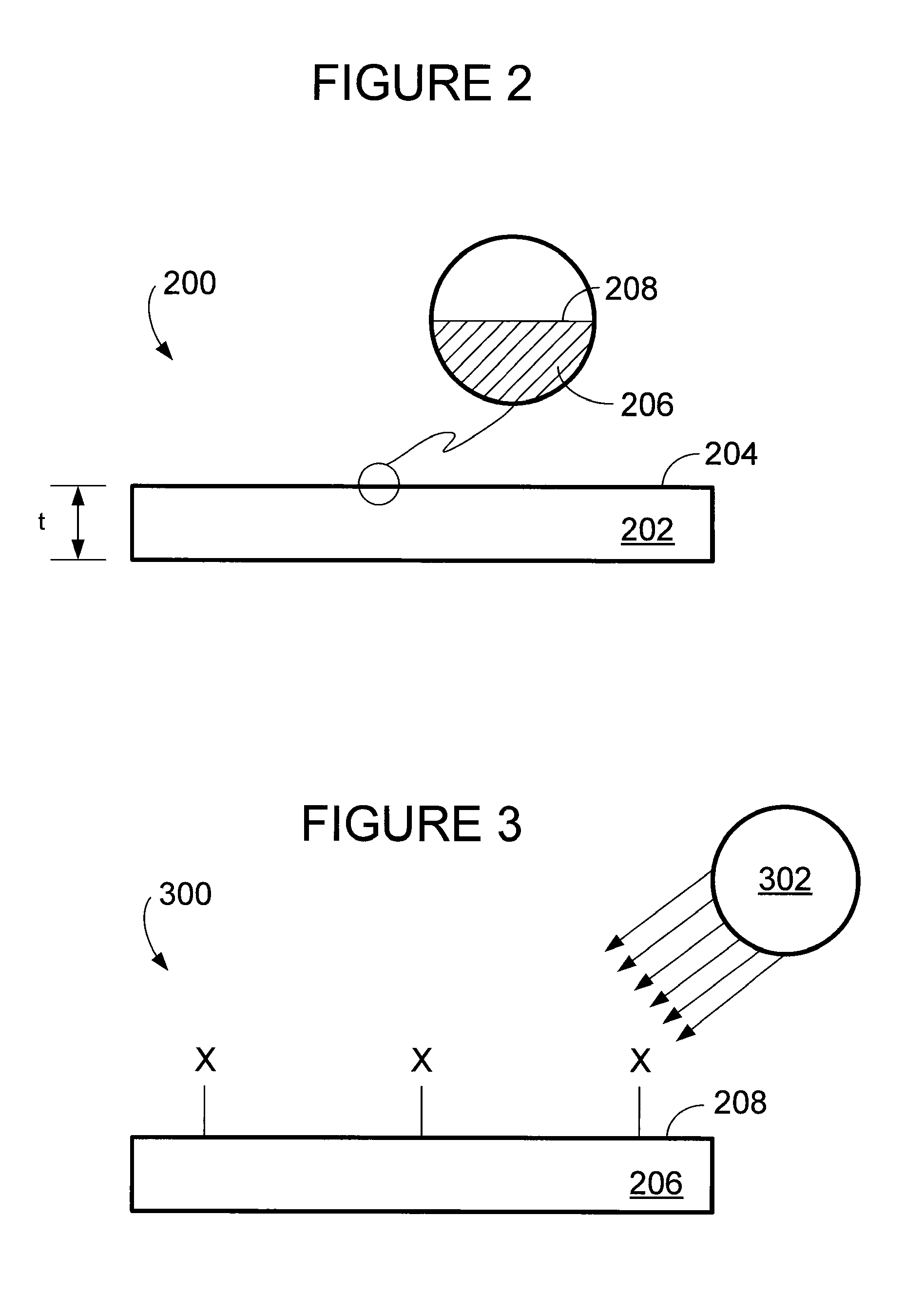

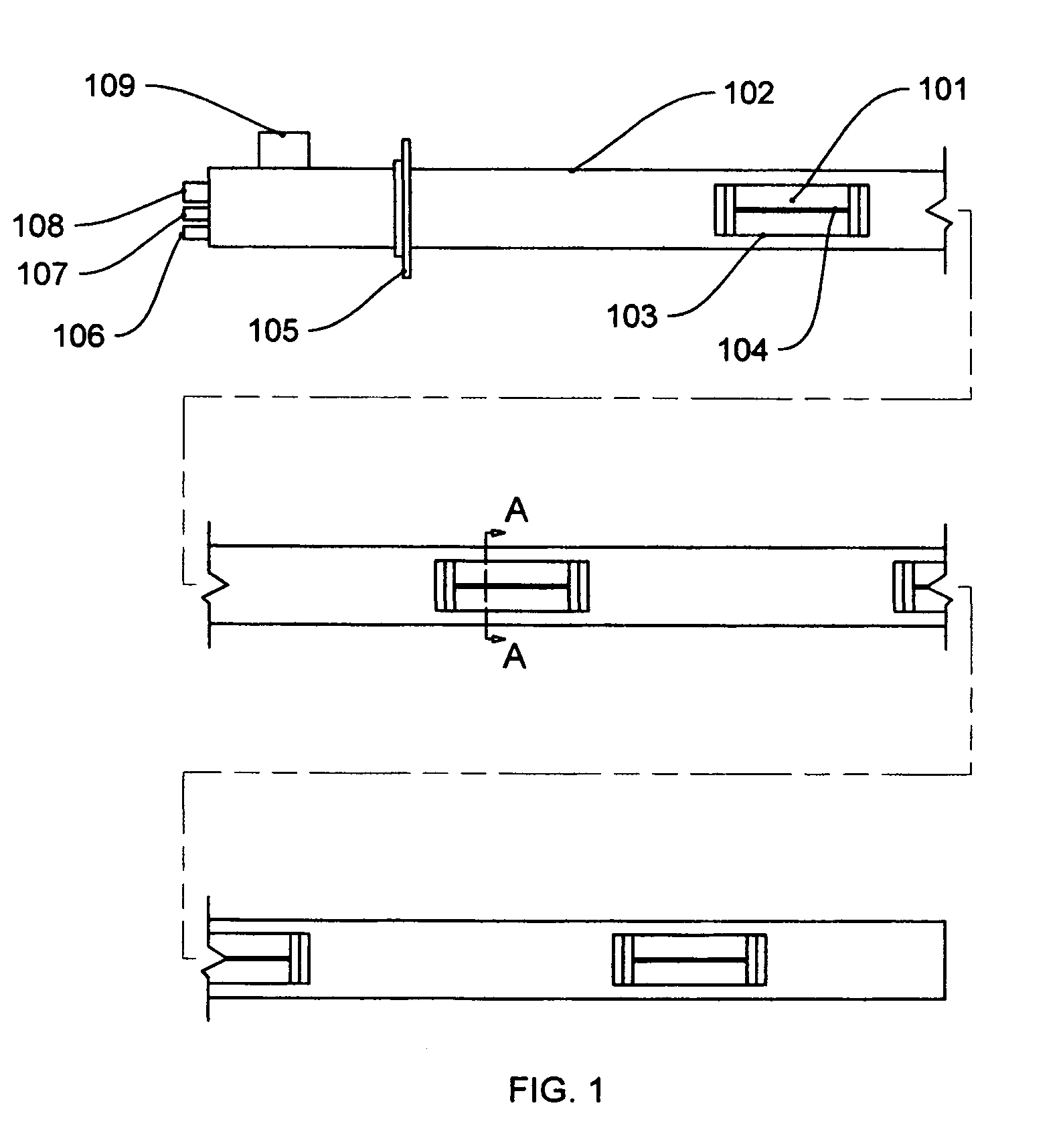

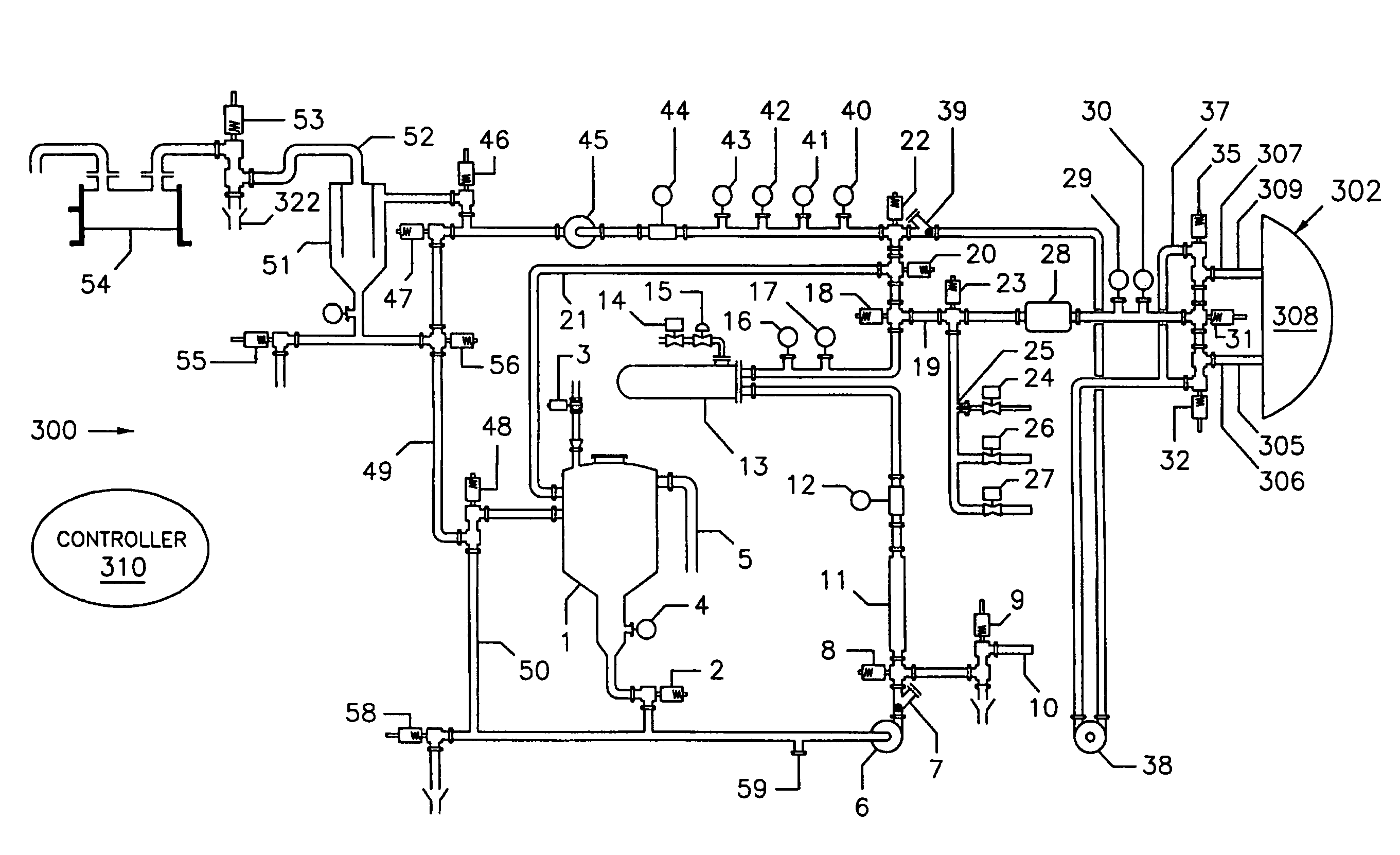

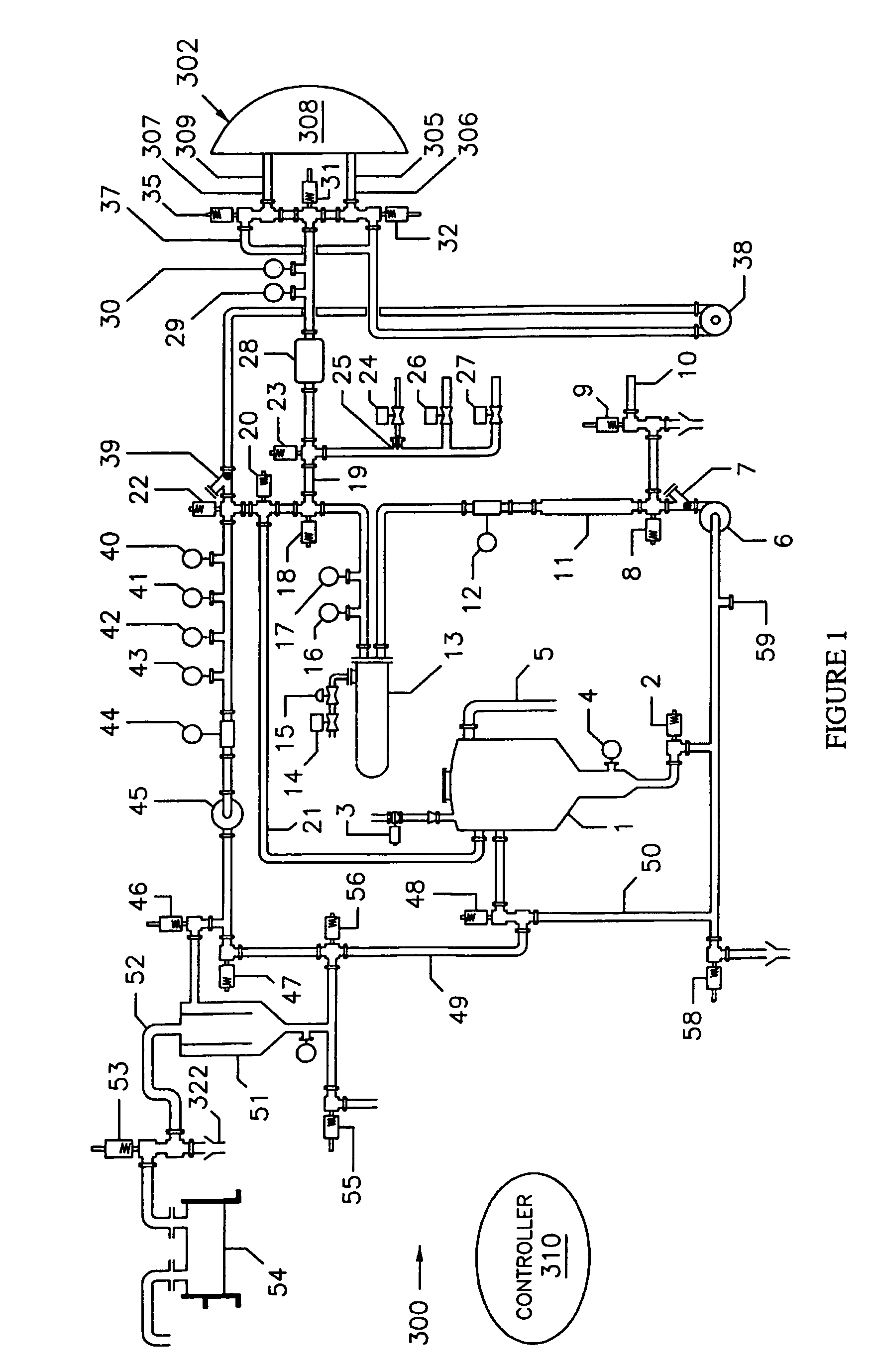

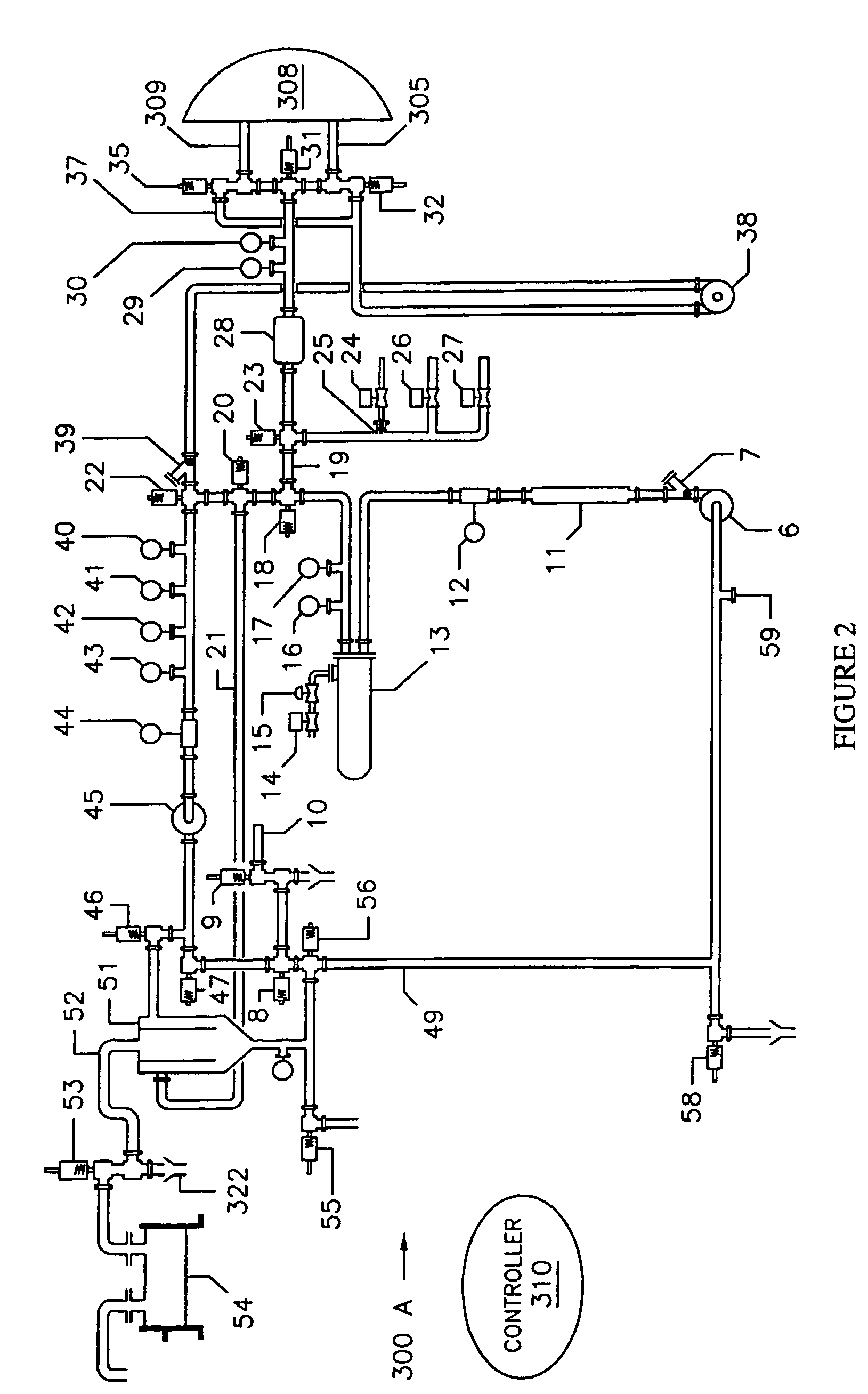

Cleaning Method and Apparatus

ActiveUS20080210262A1Improve cleaning methodsEasy to cleanHollow article cleaningSpraying apparatusInternal pressureEngineering

A method for cleaning an interior surface of a processing equipment using a treatment liquid, the processing equipment including a pipe section defining pipe section first and second ends, the pipe section defining a pipe section volume delimited by the pipe section first and second ends, the pipe section being initially at an initial internal pressure. The method includes introducing a predetermined volume of the treatment liquid, the predetermined volume being substantially smaller than the pipe section volume circulating the predetermined volume of the treatment liquid through the pipe section by simultaneously reducing an internal pressure within the pipe section at a location substantially adjacent the pipe section second end and increasing an internal pressure within the pipe section at a location substantially adjacent the pipe section first end.

Owner:LAUZON NORMAND

Methods and formulations for protection ans dust control involving bulk material

InactiveUS20100112224A1Reduce surface tensionImprove surface wettingOther chemical processesPretreated surfacesWater insolubleDust control

A novel two component system is described to apply various formulations for dust suppression and protection of bulk material. The system provides a method to apply the two formulations which result in a temporary, water insoluble, flexible, semipermeable film being formed on the surface to which the formulations are applied. The formulations used for the various applications are described.

Owner:LOTT JAMES A

Interface materials and methods of production and use thereof

InactiveUS7172711B2Minimize size of deviceImprove cooling effectSemiconductor/solid-state device detailsConductive materialHeat sinkIndium

An interface material comprising a resin mixture and at least one solder material is herein described. The resin material may comprise any suitable resin material, but it is preferred that the resin material be silicone-based comprising one or more compounds such as vinyl silicone, vinyl Q resin, hydride functional siloxane and platinum-vinylsiloxane. The solder material may comprise any suitable solder material, such as indium, silver, copper, aluminum and alloys thereof, silver coated copper, and silver coated aluminum, but it is preferred that the solder material comprise indium or indium-based compounds and / or alloys. The interface material, or polymer solder, has the capability of enhancing heat dissipation in high power semiconductor devices and maintains stable thermal performance. The interface material may be formulated by mixing the components together to produce a paste which may be applied by dispensing methods to any particular surface and cured at room temperature or elevated temperature. It can be also formulated as a highly compliant, cured, tacky elastomeric film or sheet for other interface applications where it can be preapplied, for example on heat sinks, or in any other interface situations.

Owner:HONEYWELL INT INC

Interface materials and methods of production and use thereof

InactiveUS20080044670A1Improve cooling effectImprove thermal performanceLayered productsSemiconductor/solid-state device detailsElastomerIndium

An interface material comprising a resin mixture and at least one solder material is herein described. The resin material may comprise any suitable resin material, but it is preferred that the resin material be silicone-based comprising one or more compounds such as vinyl silicone, vinyl Q resin, hydride functional siloxane and platinum-vinylsiloxane. The solder material may comprise any suitable solder material, such as indium, silver, copper, aluminum and alloys thereof, silver coated copper, and silver coated aluminum, but it is preferred that the solder material comprise indium or indium-based compounds and / or alloys. The interface material, or polymer solder, has the capability of enhancing heat dissipation in high power semiconductor devices and maintains stable thermal performance. The interface material may be formulated by mixing the components together to produce a paste which may be applied by dispensing methods to any particular surface and cured at room temperature or elevated temperature. It can be also formulated as a highly compliant, cured, tacky elastomeric film or sheet for other interface applications where it can be preapplied, for example on heat sinks, or in any other interface situations.

Owner:NGUYEN MY

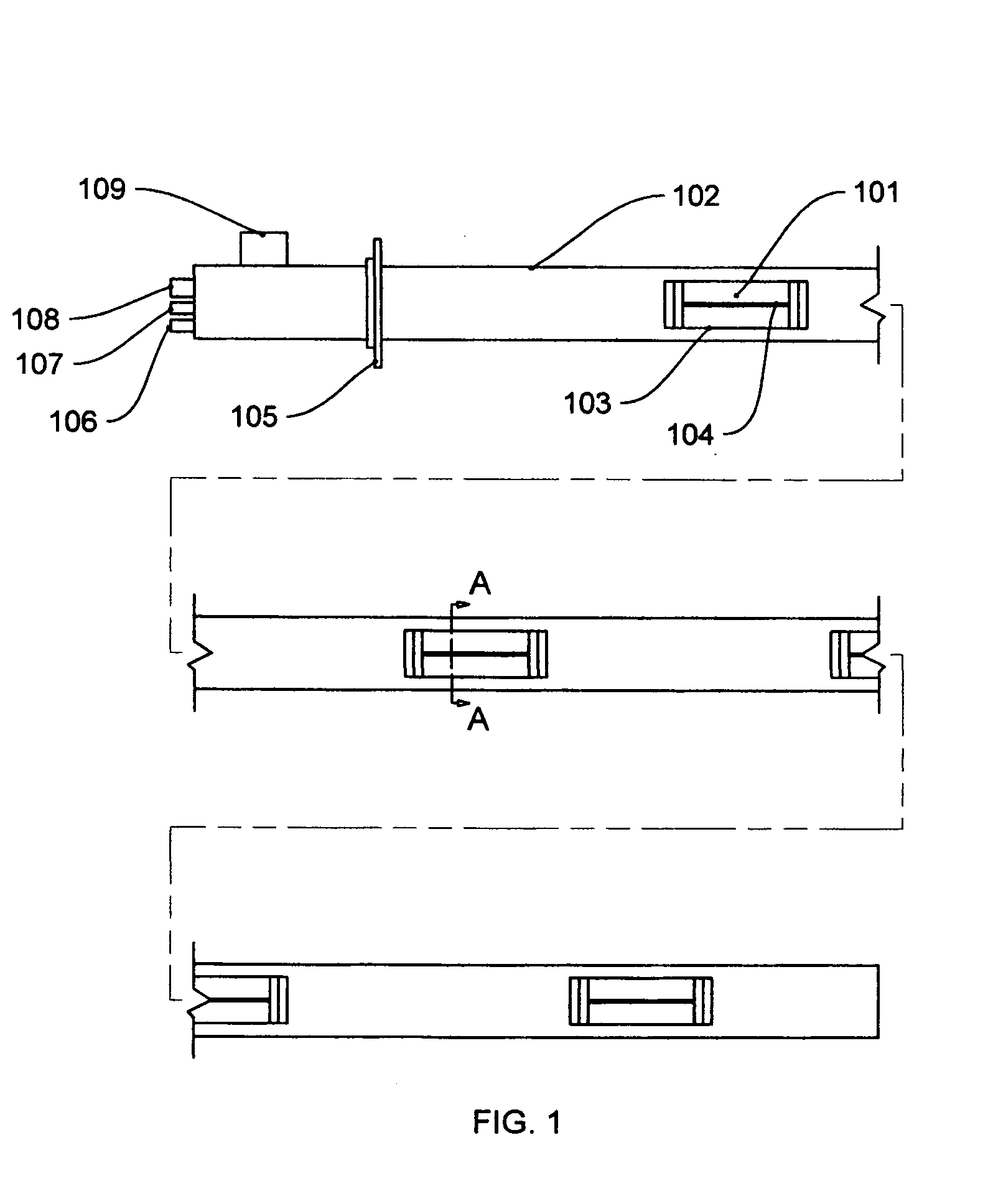

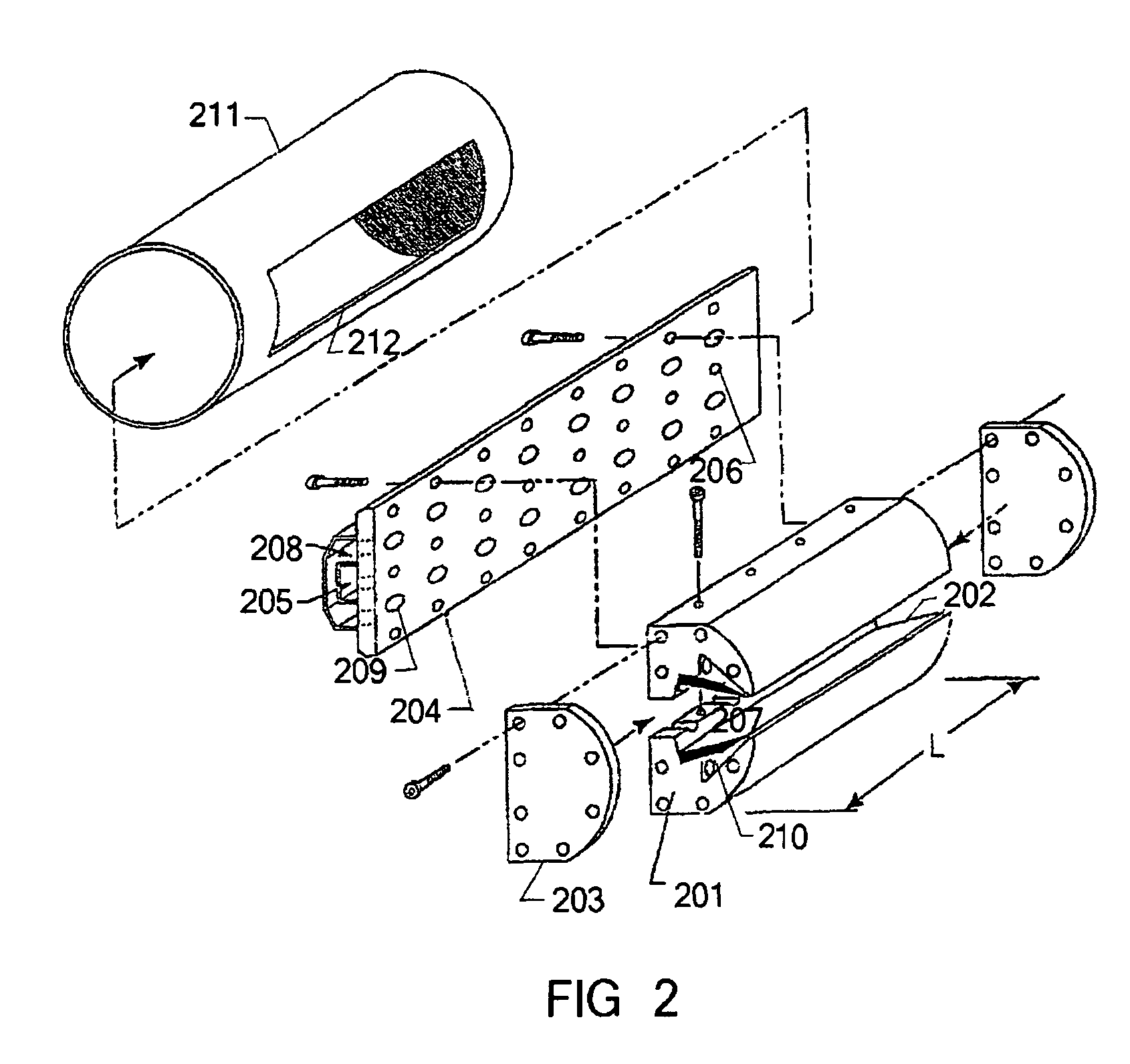

Joining the mixing and variable gas atomizing of reactive chemicals in flue gas cleaning systems for removal of sulfur oxides, nitrogen oxides and mercury

InactiveUS20100068111A1Short reaction timeIncreased time requirementCombination devicesGas treatmentAmount of substanceFossil fuel

Diverse methods of utilization and the corresponding, related modifications, of linear type, Variable Gas Atomization (VGA) nozzles and lances are described. Therein is joined the mixing and gas atomization of chemicals that react to form active products that further react with harmful flue gas constituents of combustion so as to enable their effective collection. One version combines, in a lance assembly of nozzles, the injection of reactants, in the form of finely divided dry solids conveyed in a carrier air stream, and the fine atomization of water, aqueous solutions or slurries. Atomization of such streams is employed to effectively wet the surfaces of the dry particles and, thereby, promote the rapid sorption of gaseous constituents of flue gas being treated. Another version simultaneously mixes and atomizes reacting chemicals to produce, and release into the flue gas stream, strongly oxidizing, transient, species of their reaction products. The simultaneous atomization and chemical reaction enables the effective capture of targeted flue gas constituents. An accompanying flue gas duct modification is described providing means for cost effective, high-performance system operation of linear VGA nozzle-lance arrays, as components of the various subject flue gas cleaning processes. The combination of linear VGA nozzle-lances and, as needed, flue gas duct enhancement, is intended to provide an economical and technically practicable means of retrofitting existing fossil fueled boilers of a wide range of capacities to meet future emission limits for SO2, SO3, NOx and mercury.

Owner:WALSH JR WILLIAM ARTHUR

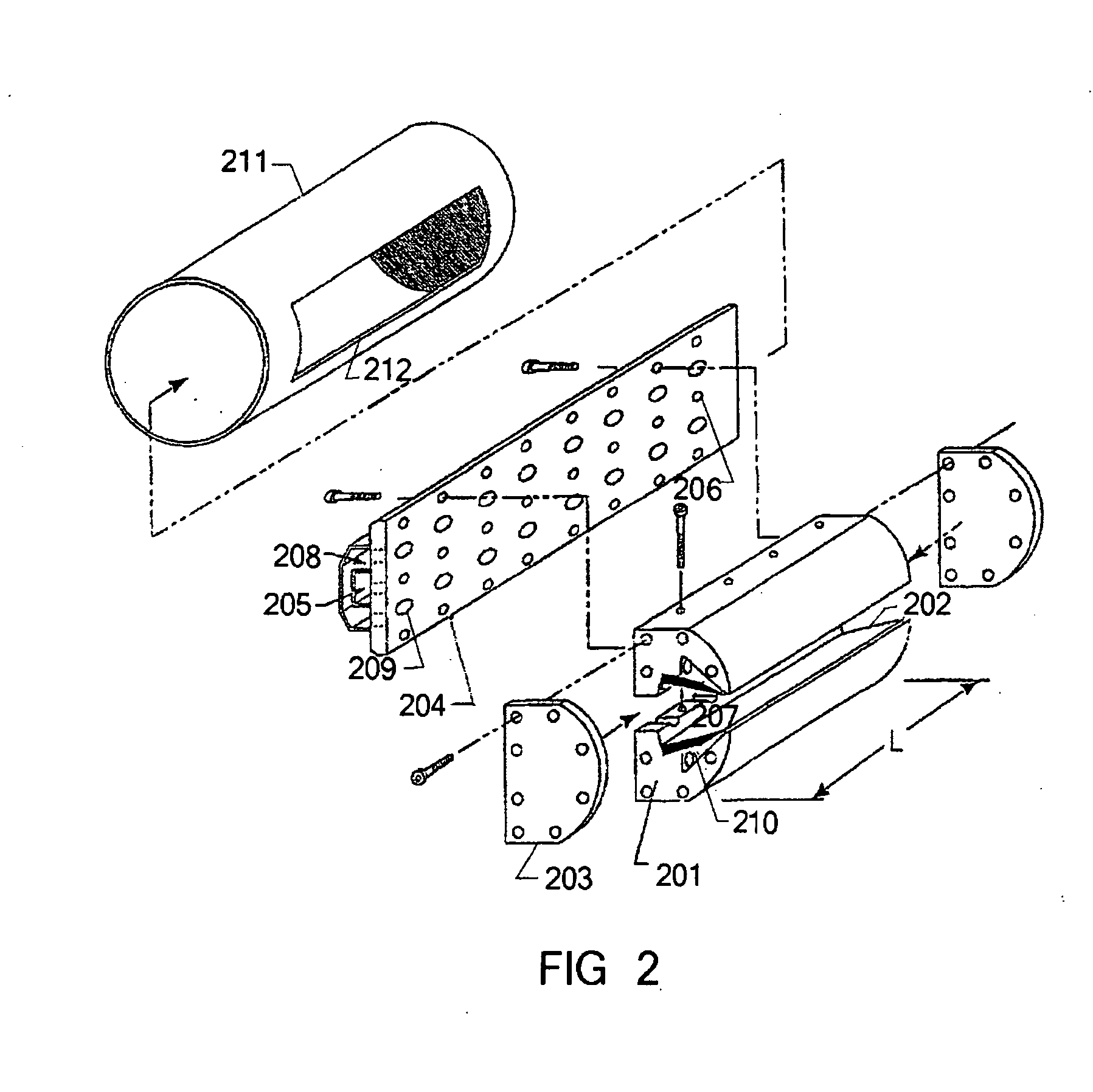

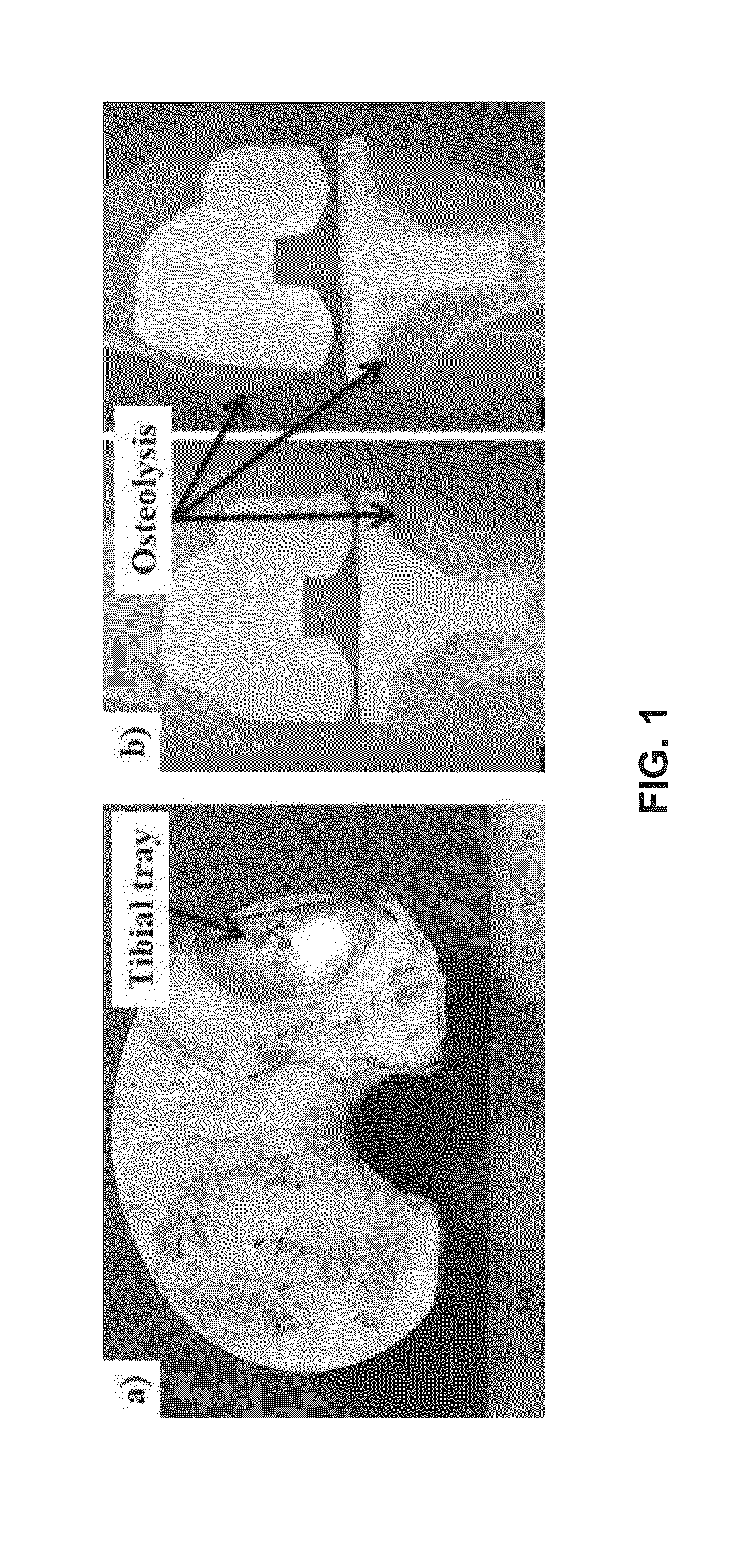

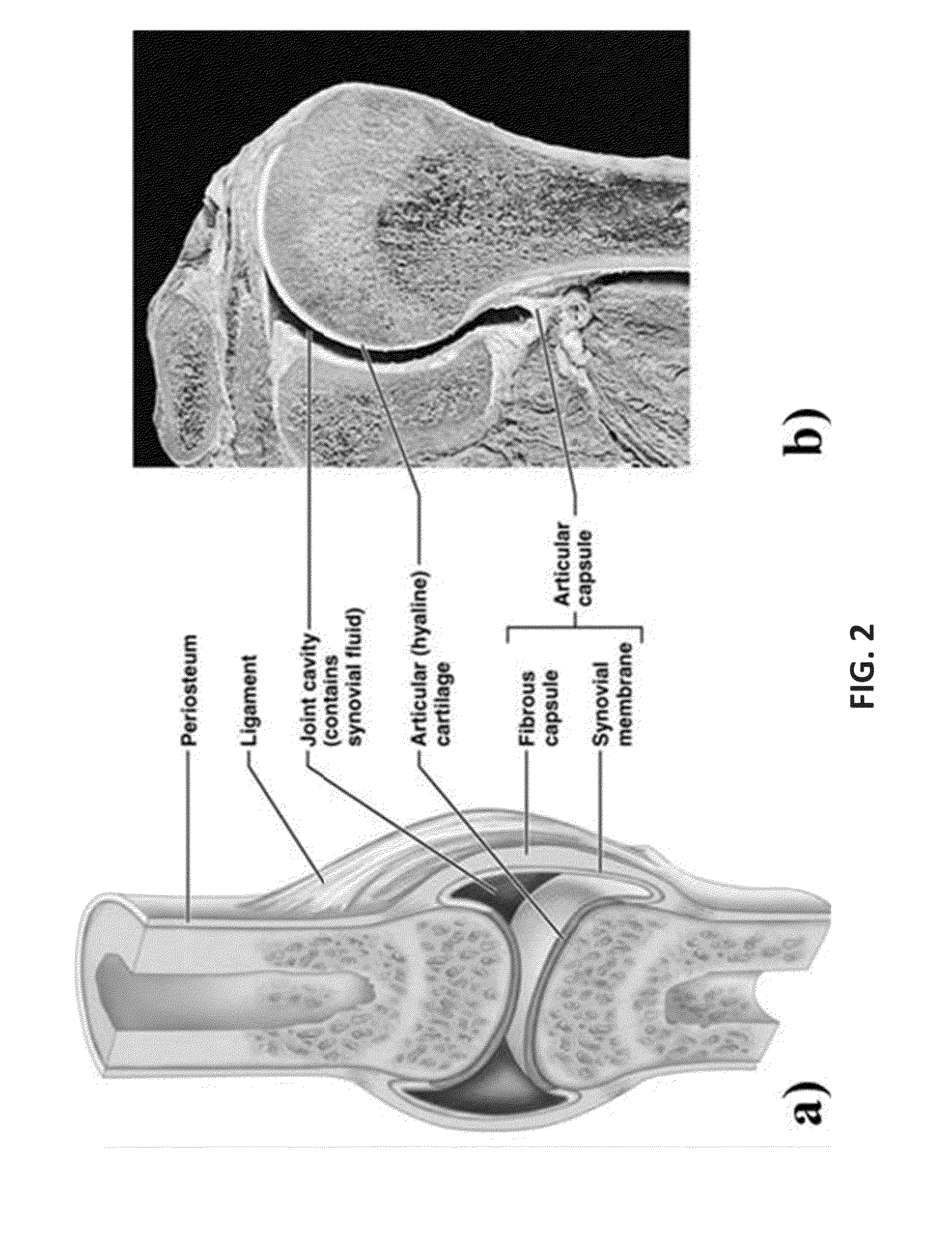

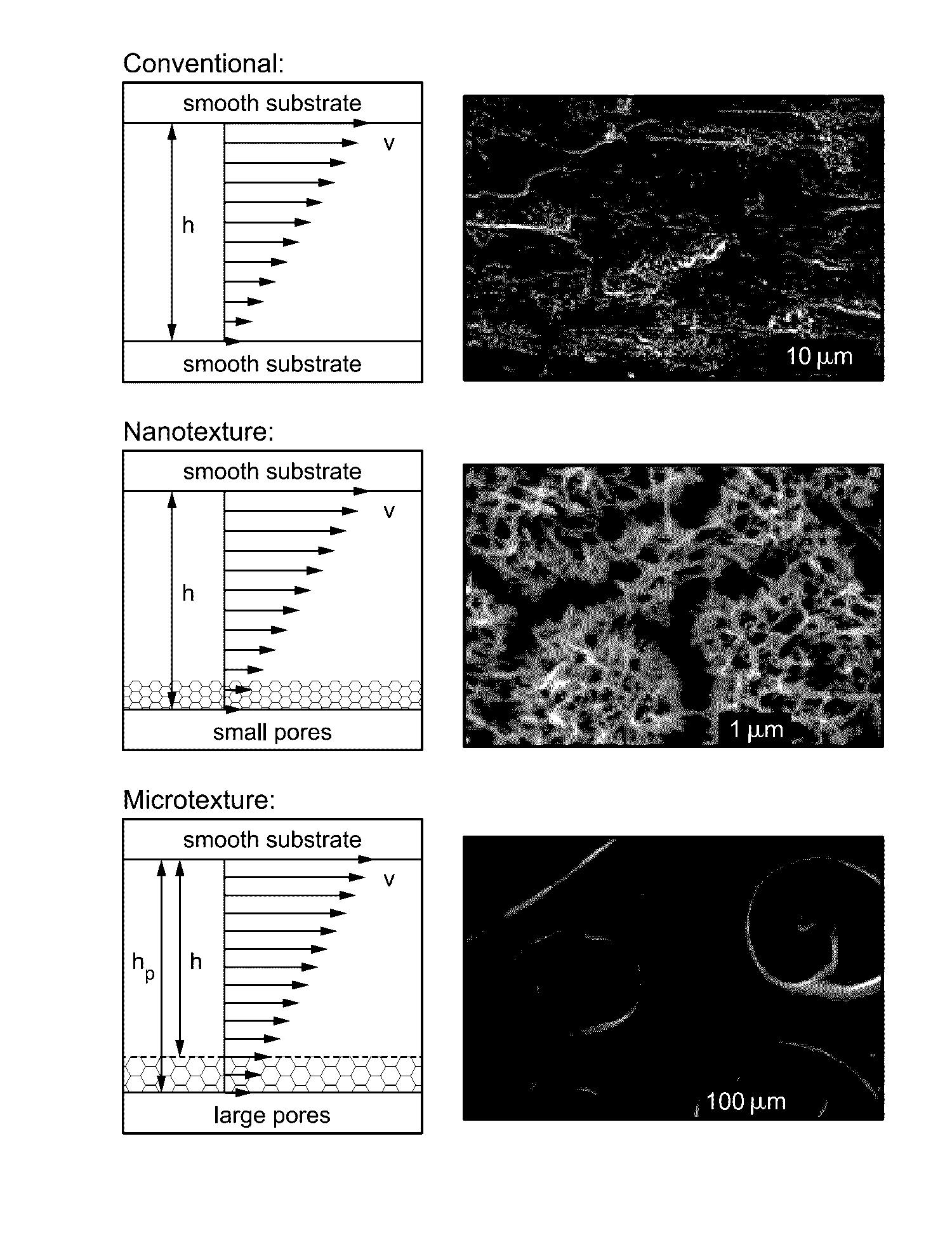

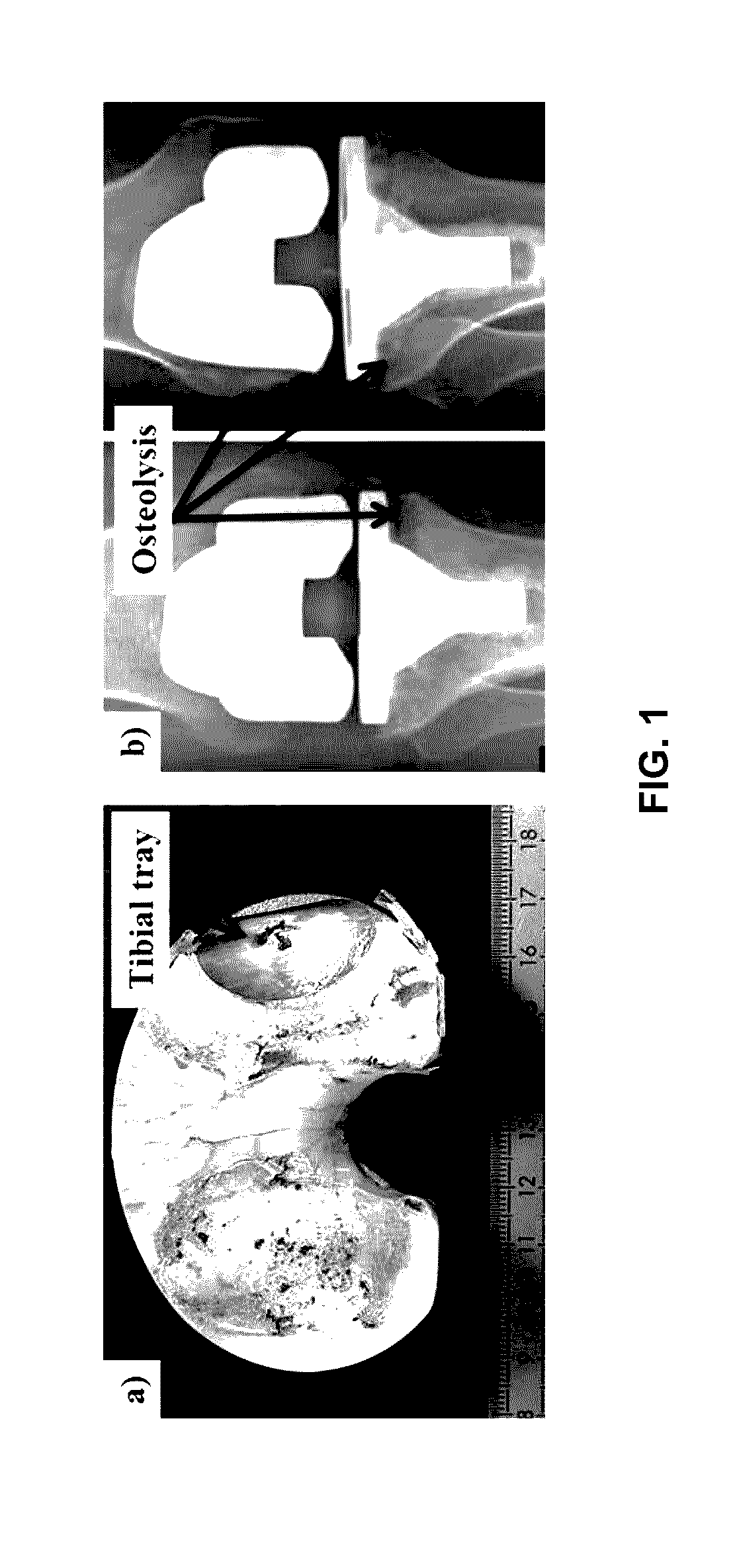

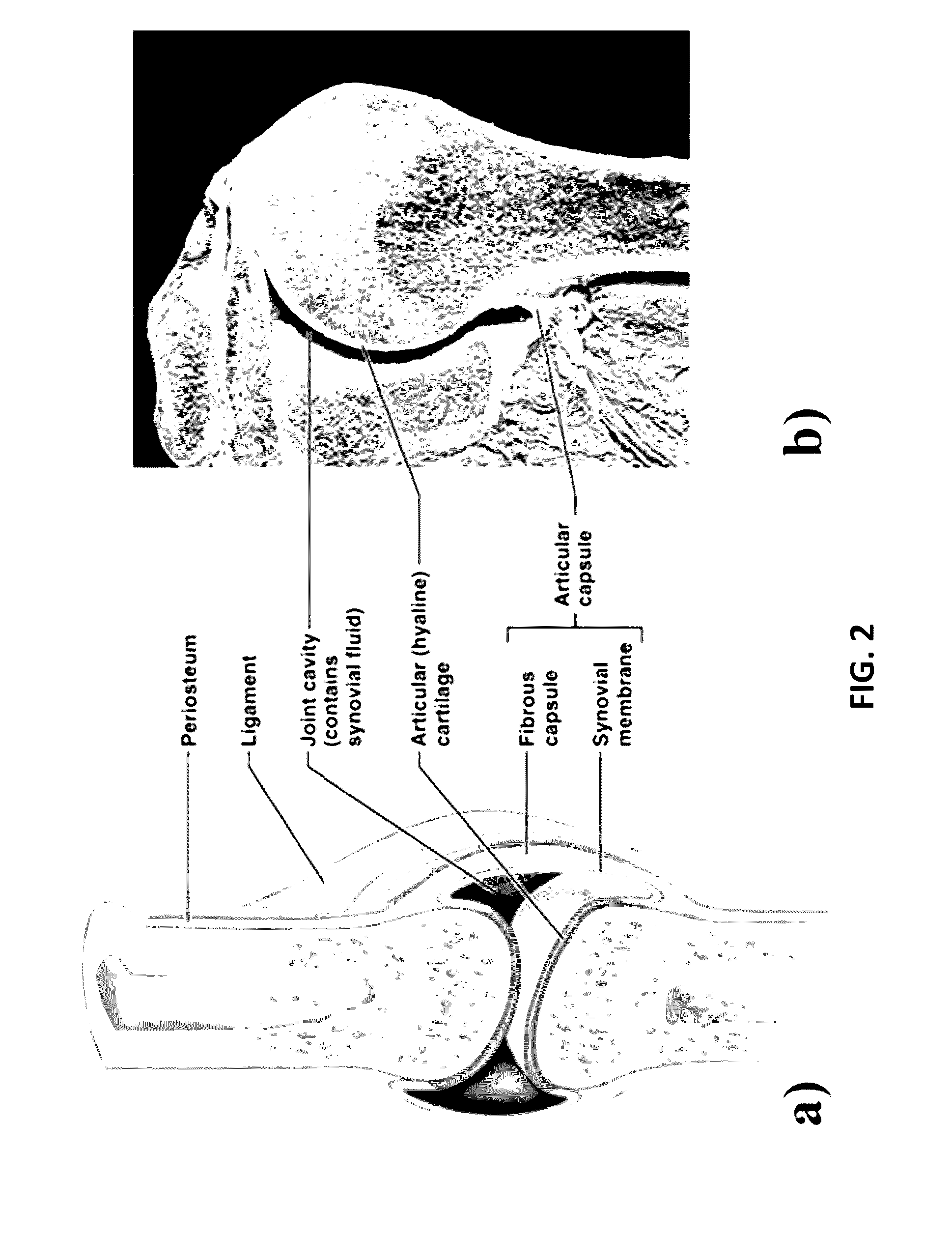

Orthopaedic Joints Providing Enhanced Lubricity

ActiveUS20150066152A1Increase surface lubricityWear minimizationJoint implantsProsthesisProsthetic joint component

The present disclosure provides, among other things, prosthetic joint components having textured surface(s) for improving lubrication and increasing the useful life of the prosthetic joint components. The textured surface includes solid features configured to stably contain a biological fluid or a synthetic biological fluid therebetween or therewithin for a non-zero residence time.

Owner:MASSACHUSETTS INST OF TECH

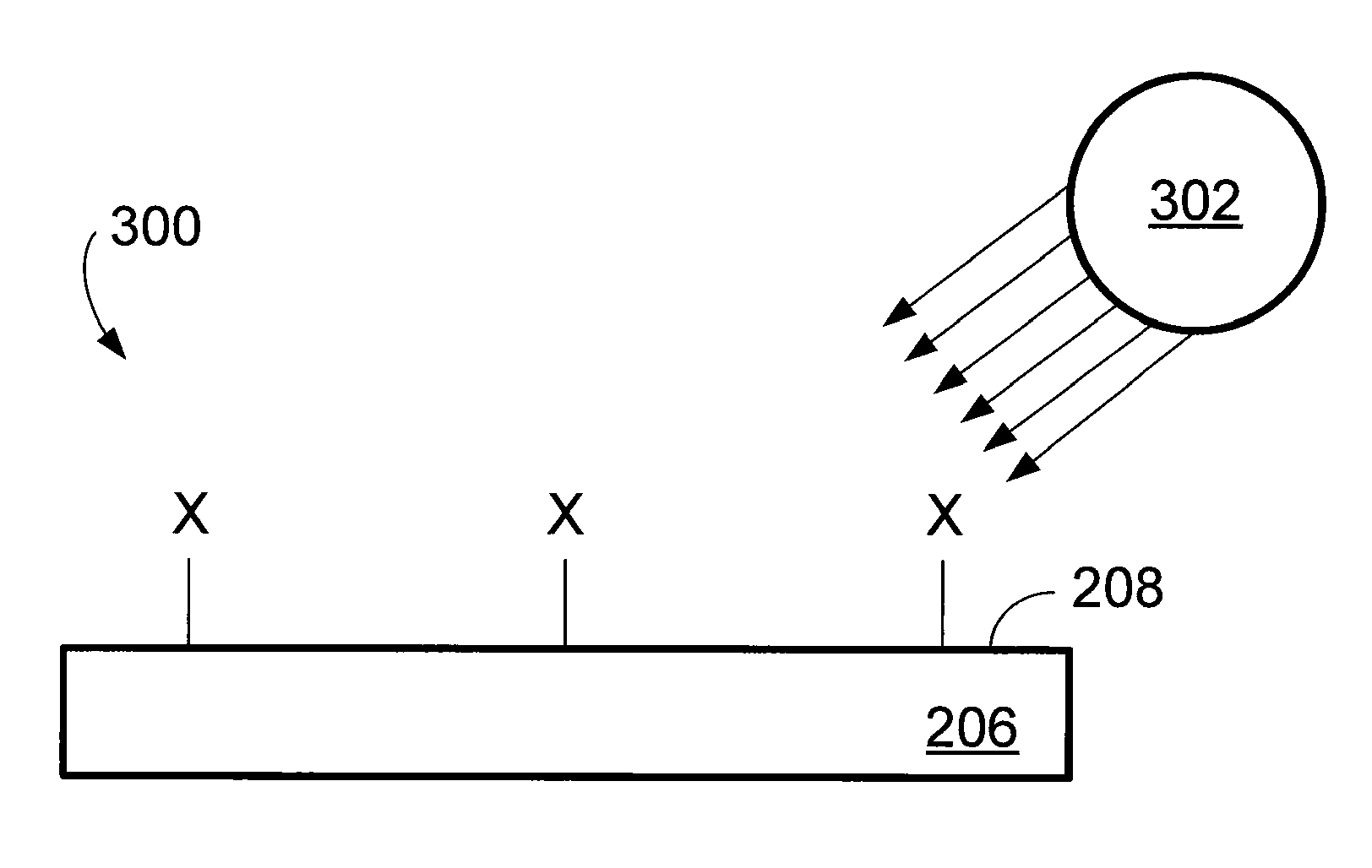

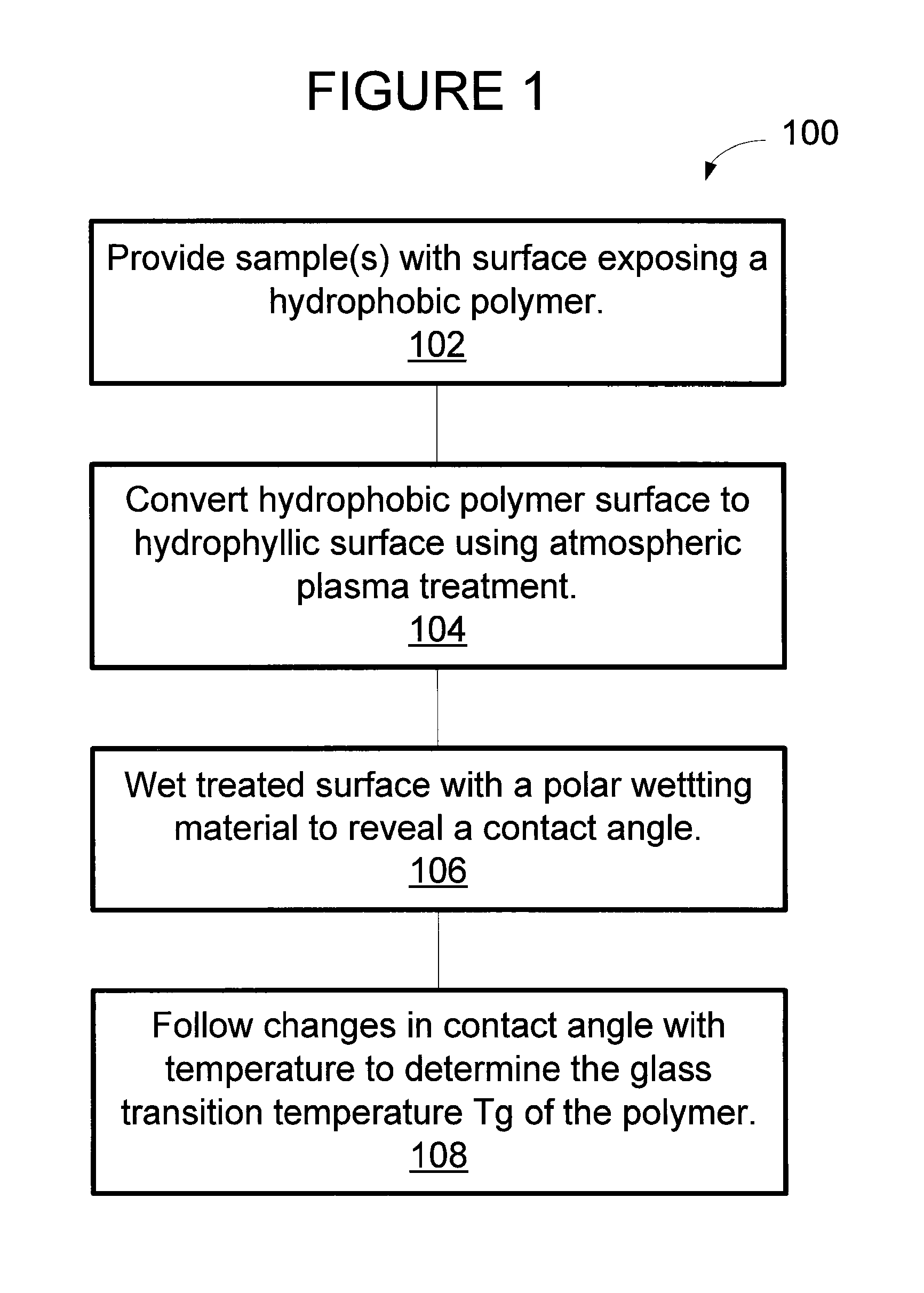

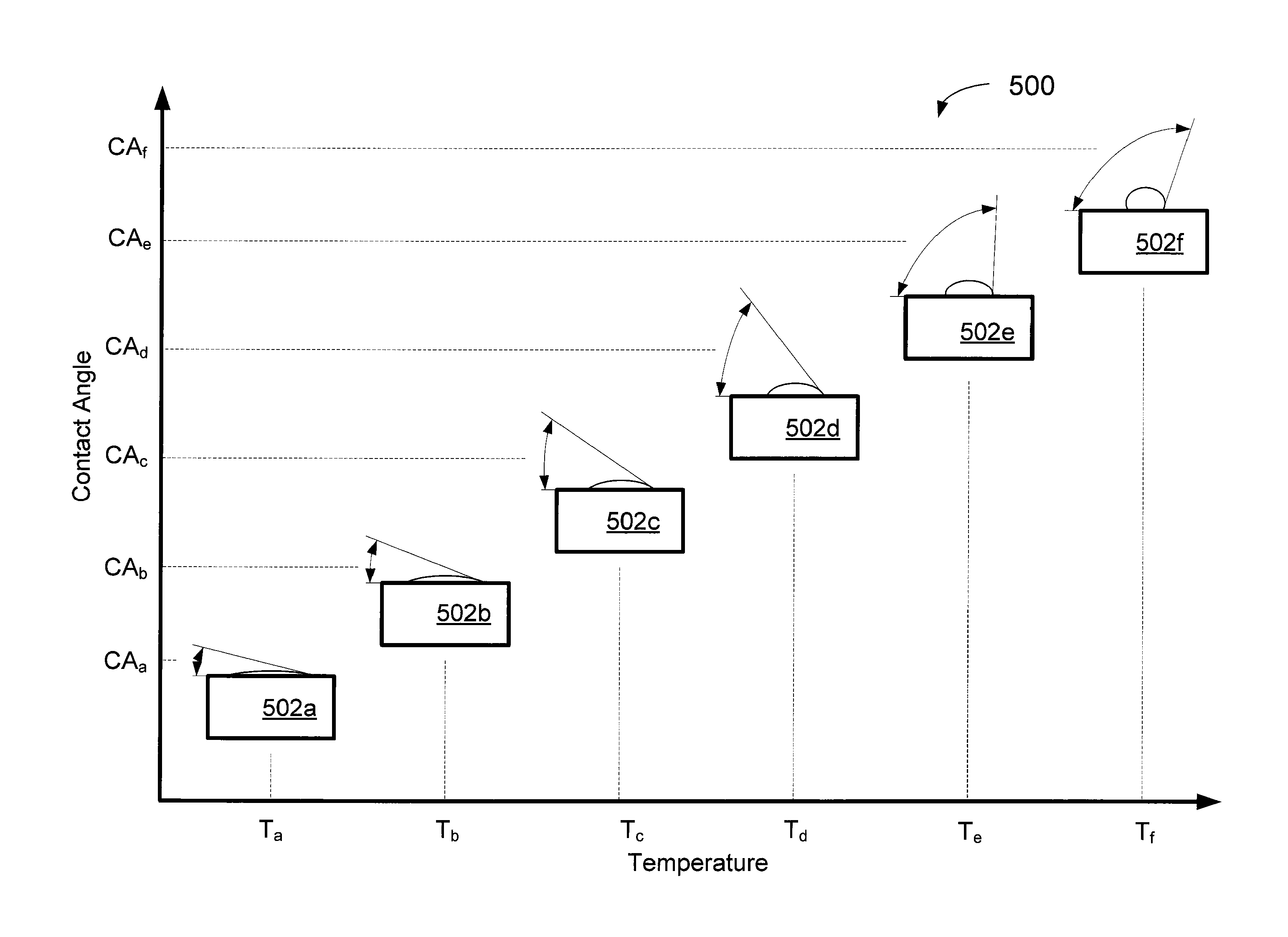

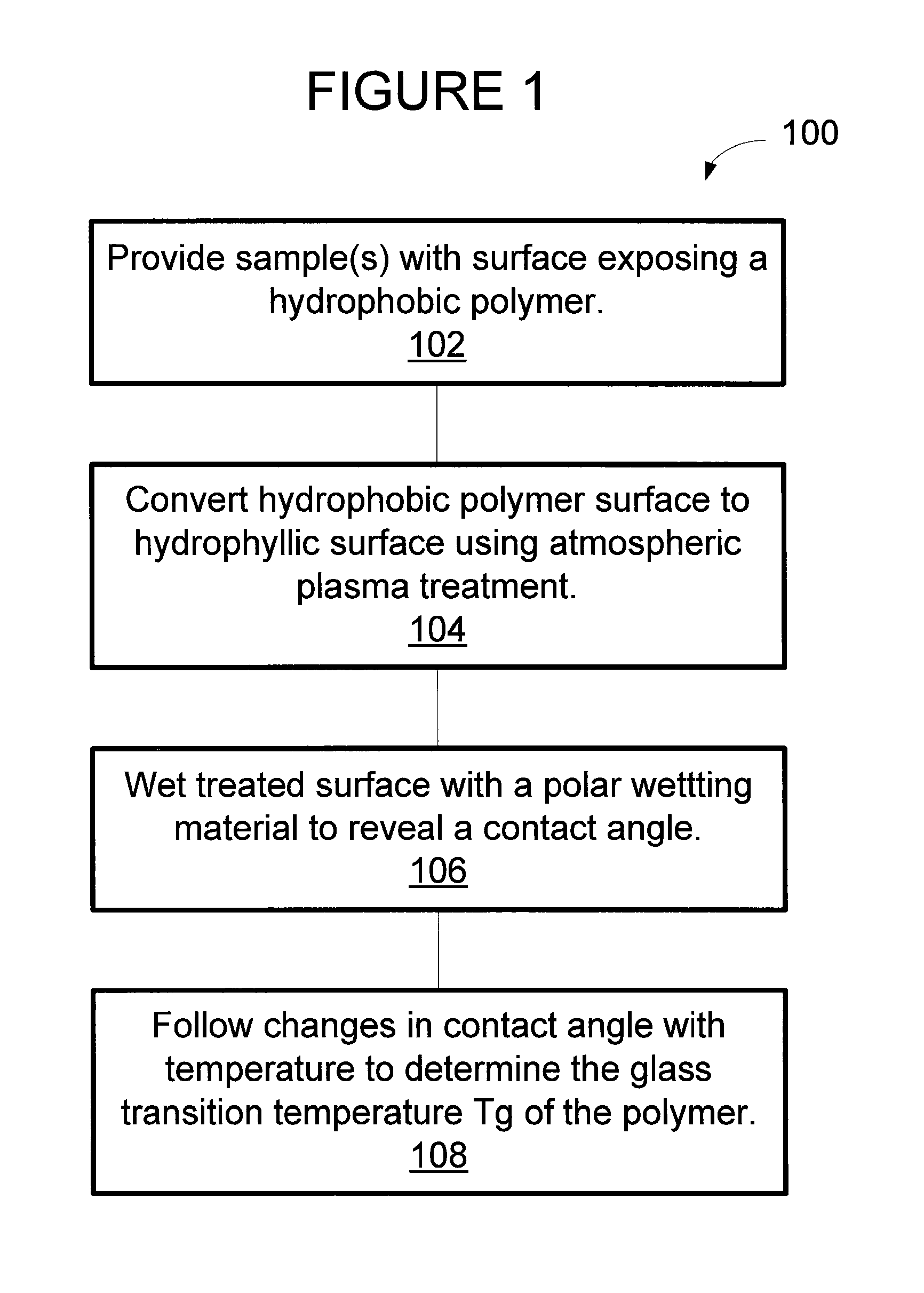

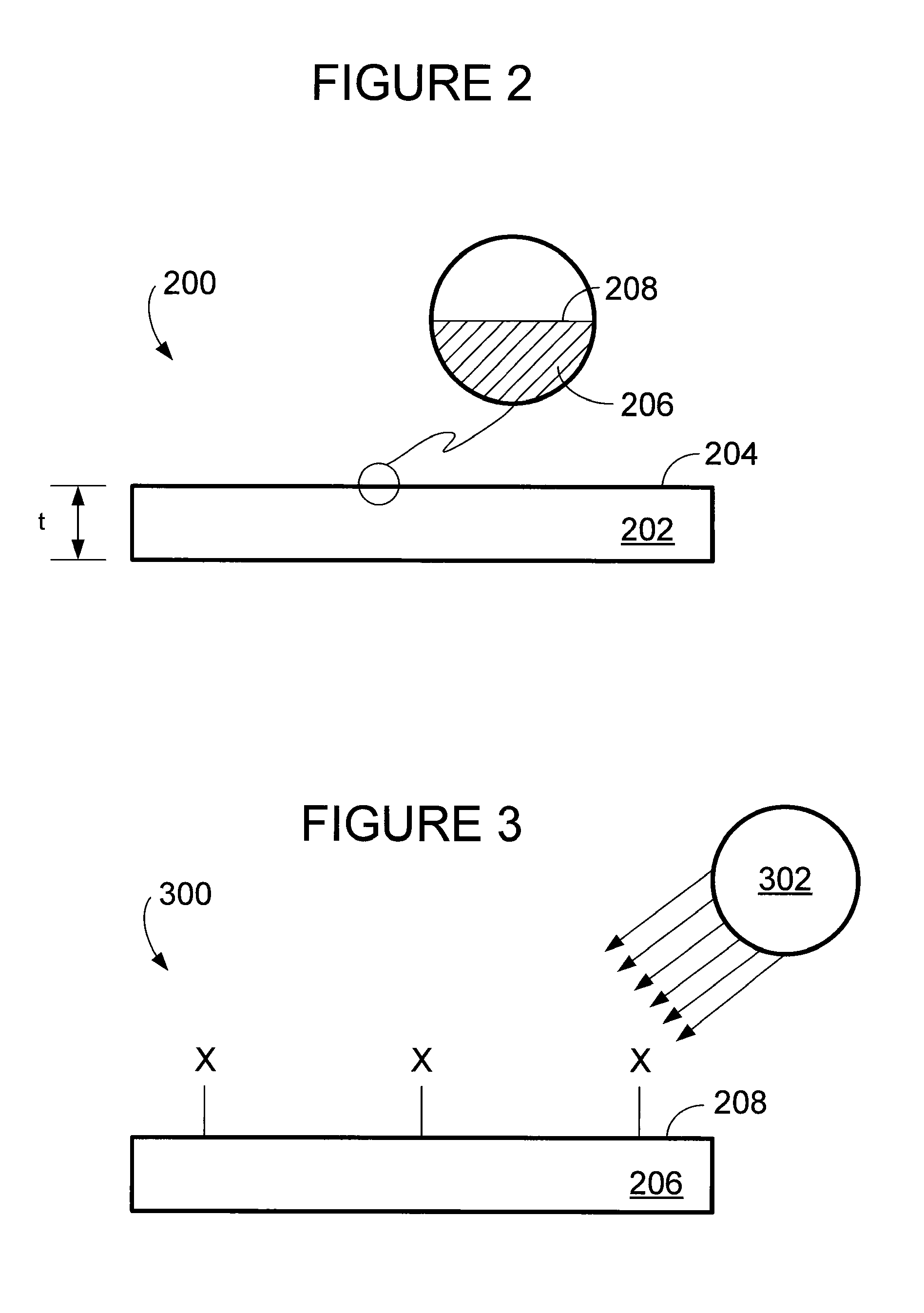

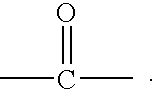

System and mehtod for measuring glass transition temperature

ActiveUS20120307860A1Improve wetting propertiesAccurate assessmentSurface/boundary effectInvestigating phase/state changeVitrificationHydrophobic polymer

A system and method for measuring a glass transition temperature of a hydrophobic polymer having a surface tagged with an atmospheric plasma.

Owner:THE AEROSPACE CORPORATION

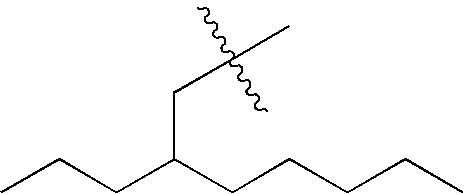

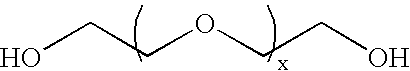

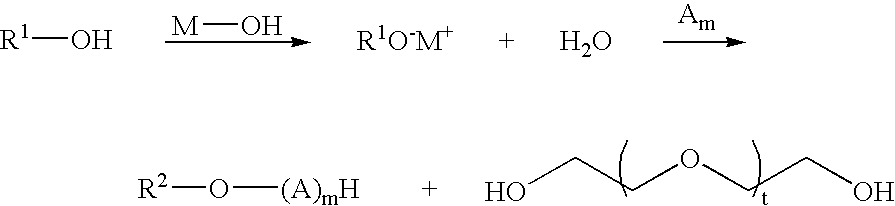

Surfactant composition and method of forming

InactiveUS7504373B2Reduce surface tensionImprove performanceBiocideOrganic detergent compounding agentsActive agentPhysical chemistry

A surfactant composition includes a first surfactant, a second surfactant, and a polyalkylene glycol. The first surfactant is of the general formula R1—O—(A)mH, wherein R1 is an aliphatic hydrocarbon having 10 carbon atoms, A is an alkyleneoxy group having from 2 to 5 carbon atoms, and m is a positive number. The second surfactant is of the general formula R2—O—(B)nH, wherein R2 is an aliphatic hydrocarbon having from 12 to 14 carbon atoms, B is an alkyleneoxy group having from 2 to 5 carbon atoms, and n is a positive number. The polyalkylene glycol is present in the surfactant composition in an amount of from 3 to 20 parts by weight per 100 parts by weight of the surfactant composition.

Owner:BASF CORP

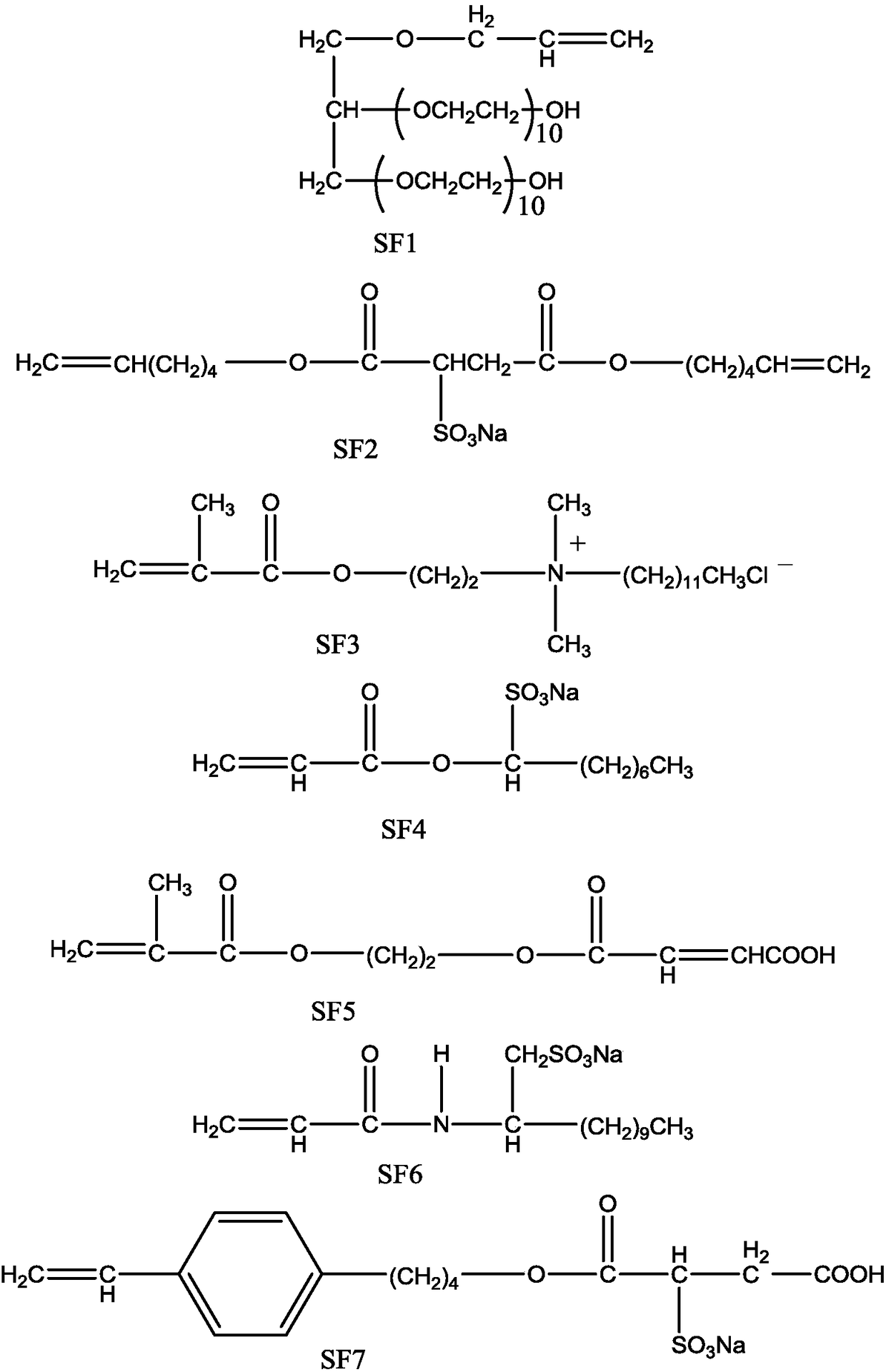

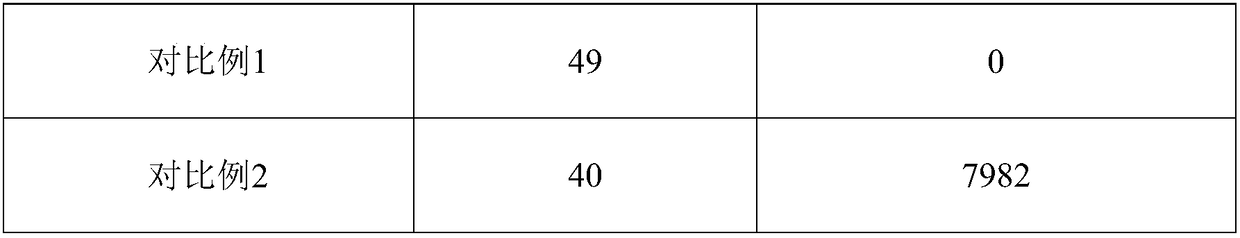

Polymerizable surfactant containing acrylic acid water-absorbent resin as well as preparation method and application thereof

The invention provides polymerizable surfactant containing acrylic acid water-absorbent resin as well as a preparation method and an application thereof. The polymerizable surfactant contains hydrophilic and lipophilic groups as well as polymerizable carbon-carbon double bond, and thus can reduce the solution interfacial tension to stabilize bubbles before acrylic acid polymerization, and is helpful in preparing hydrogel with a porous structure; and moreover, the polymerizable surfactant can participate in the polymerization after the reaction begins and is embedded in the surface of the hydrogel network structure, so as to improve the surface hydrophilcity of the water-absorbent resin and increase the liquid absorbing rate of the product. Moreover, compared with a common surfactant, the polymerizable surfactant is not left in the resin product in a free form, thereby being safer, healthier and more environment-friendly. The added amount is 0.01-3wt% of the acrylic acid, the rate of absorbing normal saline by the obtained acrylic acid water-absorbent resin is not lower than 40s, and the residual amount of the polymerizable surfactant is not higher than 300ppm.

Owner:WANHUA CHEM GRP

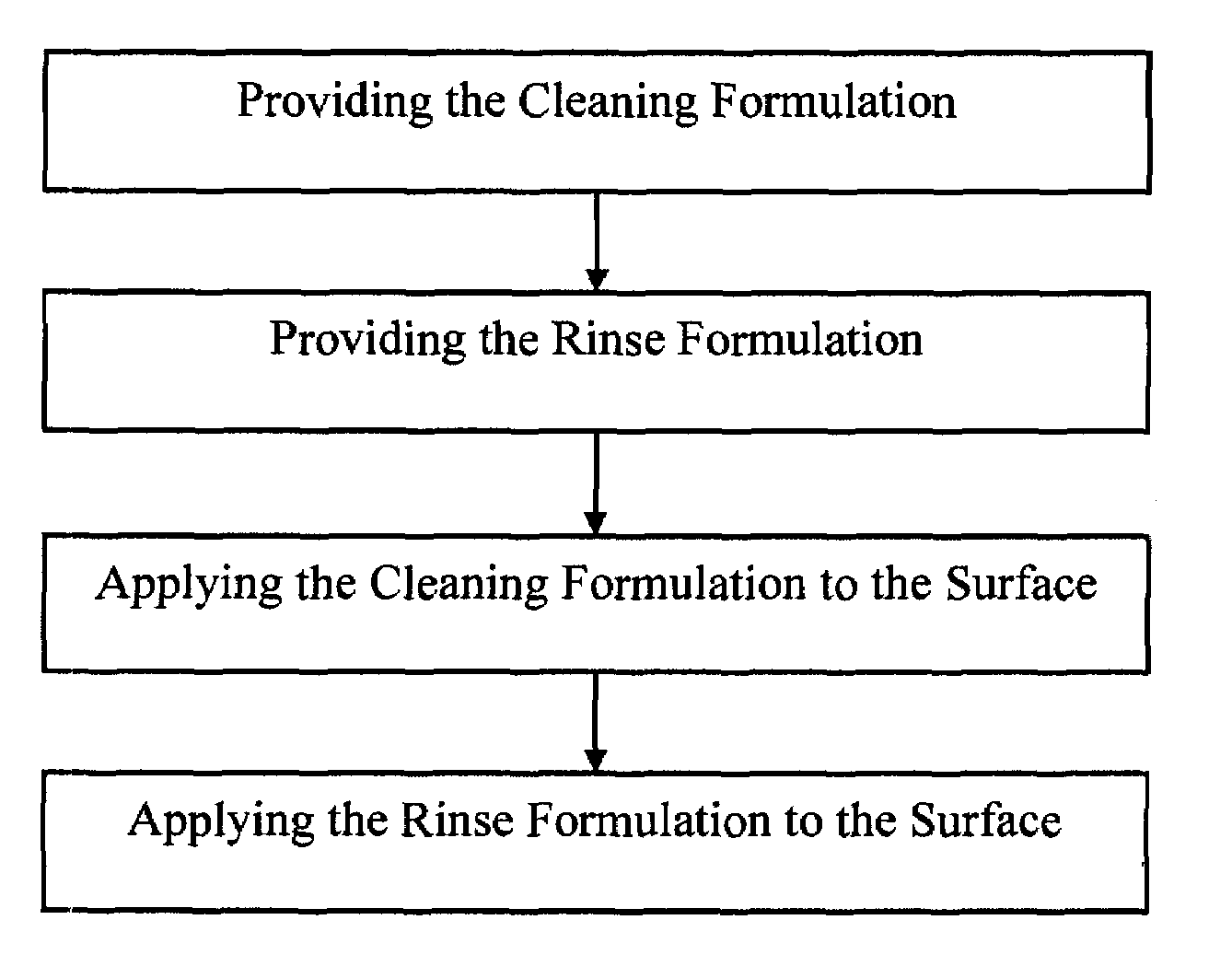

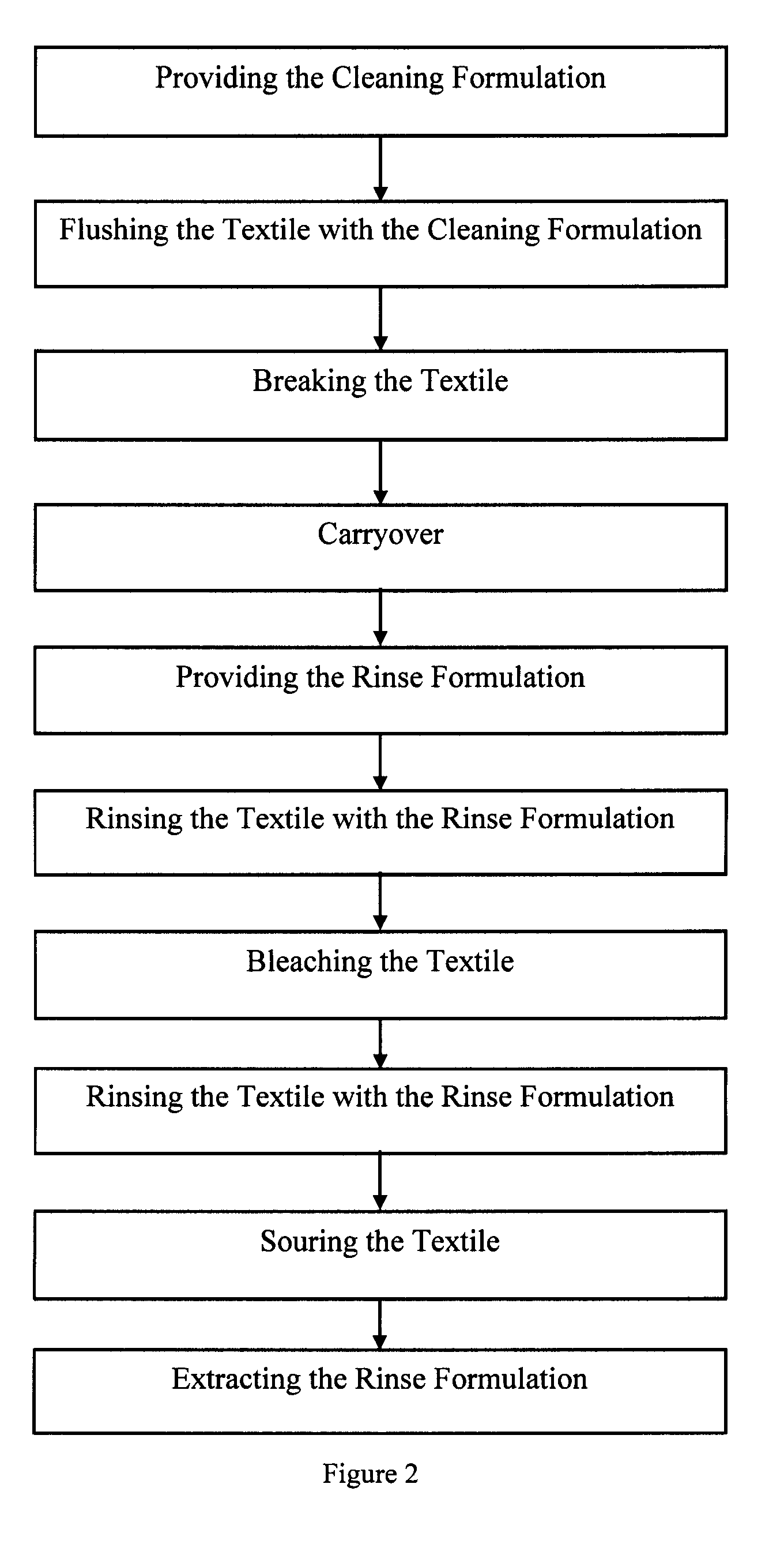

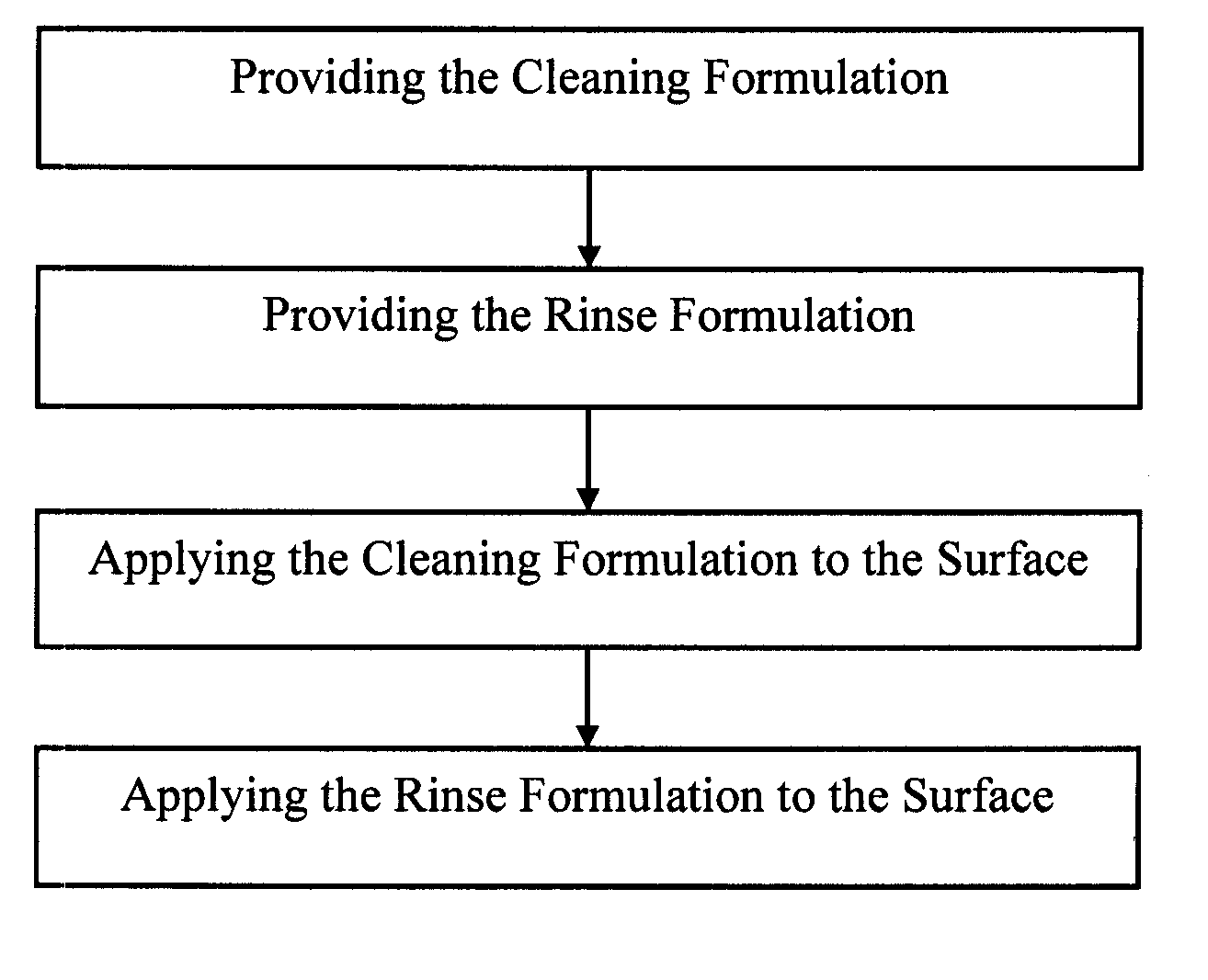

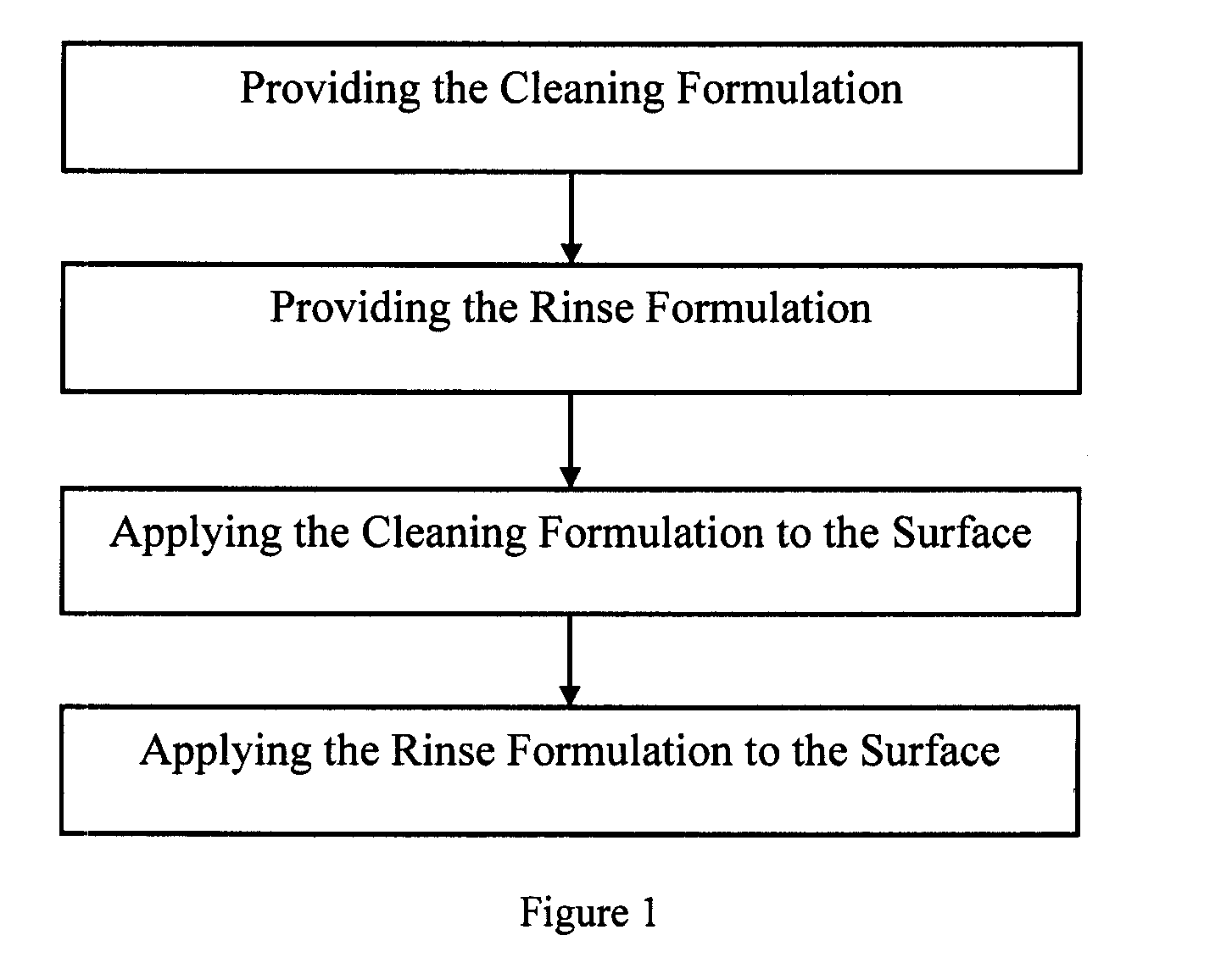

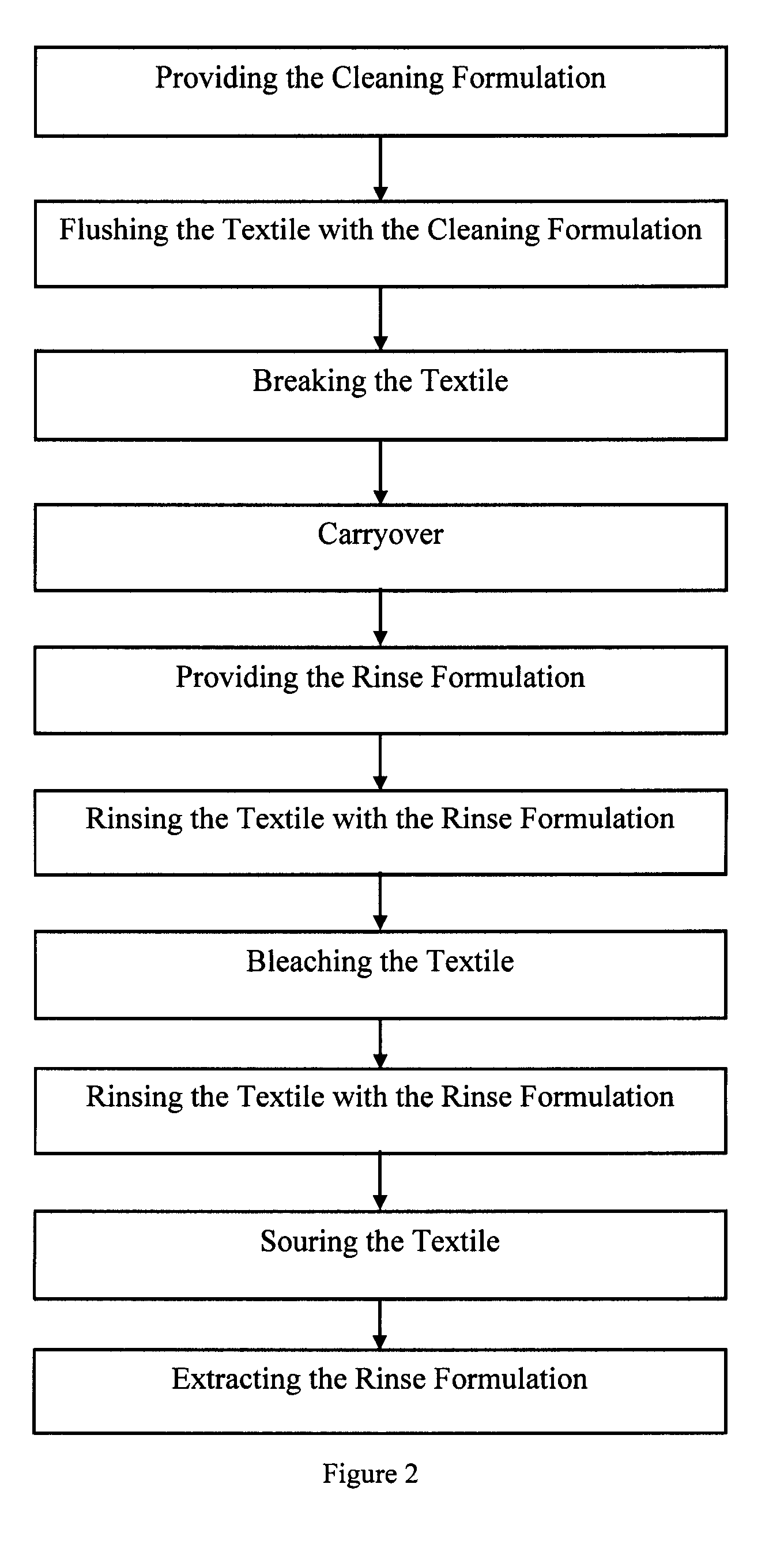

Method of washing a surface with a surfactant composition

ActiveUS7503333B2Efficient washingQuantity minimizationBiocideOrganic detergent compounding agentsAlkoxy groupActive agent

A method of washing a surface includes the step of providing a cleaning formulation including a surfactant composition including a first surfactant, a second surfactant, and a polyalkylene glycol. The first surfactant has the general formula: R1—O-(A)mH. R1 is an aliphatic hydrocarbon having from 8 to 11 carbon atoms, A is an alkyleneoxy group having from 2 to 5 carbon atoms, and m is a positive number. The second surfactant has the general formula: R2—O-(B)nH. R2 is an aliphatic hydrocarbon having from 12 to 14 carbon atoms, B is an alkyleneoxy group having from 2 to 5 carbon atoms, and n is a positive number. The polyalkylene glycol is present in an amount of from 3 to 20 parts by weight. The method also includes providing a rinse formulation, applying the cleaning formulation to the surface, and applying the rinse formulation to the surface.

Owner:BASF SE

Joining the mixing and variable gas atomizing of reactive chemicals in flue gas cleaning systems for removal of sulfur oxides, nitrogen oxides and mercury

InactiveUS7731100B2Affordable retrofit and new installation costQuick wetCombination devicesGas treatmentChemical reactionSlurry

Diverse methods of utilization and the corresponding, related modifications, of linear type, Variable Gas Atomization (VGA) nozzles and lances are described. Therein is joined the mixing and gas atomization of chemicals that react to form active products that further react with harmful flue gas constituents of combustion so as to enable their effective collection. One version combines, in a lance assembly of nozzles, the injection of reactants, in the form of finely divided dry solids conveyed in a carrier air stream, and the fine atomization of water, aqueous solutions or slurries. Atomization of such streams is employed to effectively wet the surfaces of the dry particles and, thereby, promote the rapid sorption of gaseous constituents of flue gas being treated. Another version simultaneously mixes and atomizes reacting chemicals to produce, and release into the flue gas stream, strongly oxidizing, transient, species of their reaction products. The simultaneous atomization and chemical reaction enables the effective capture of targeted flue gas constituents.

Owner:WALSH JR WILLIAM ARTHUR

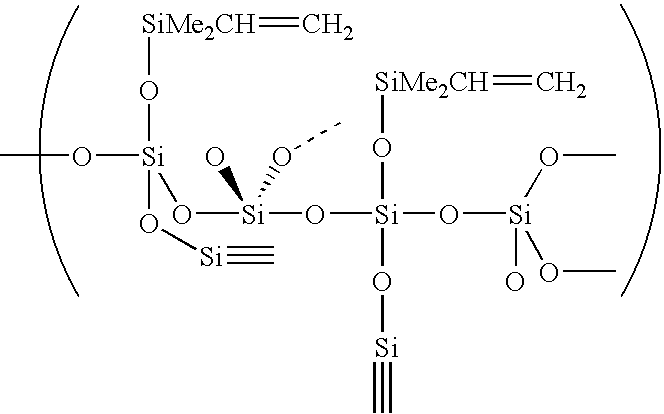

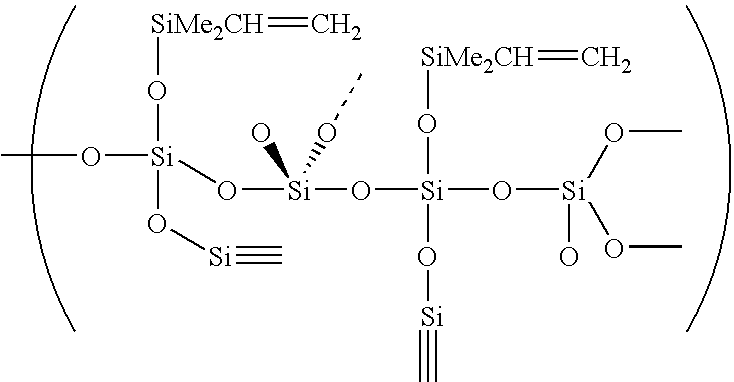

Block polyorganosiloxane block organomer polymers and release agents

InactiveUS20030232948A1Promote wettingImprove surface wettingPretreated surfacesElectrographic process apparatusPolymer scienceOrganic polymer

A polyorganosiloxane block hydrocarbyl block polymer having utility as a release agent in toner fusing systems. The polymer has one or more polar linkages, with each such linkage bonding a polyorganosiloxane block and a hydrocarbyl block, and also including a polar functionality.

Owner:HEIDELBERG DIGITAL +1

System and method for measuring glass transition temperature

ActiveUS8858070B2Improve wetting propertiesAccurate assessmentInvestigating phase/state changeSurface tension analysisVitrificationHydrophobic polymer

Owner:THE AEROSPACE CORPORATION

Block polyorganosiloxane block organomer polymers and release agents

InactiveUS6894137B2Promote wettingImprove surface wettingPretreated surfacesElectrographic process apparatusPolymer scienceOrganic polymer

A polyorganosiloxane block hydrocarbyl block polymer having utility as a release agent in toner fusing systems. The polymer has one or more polar linkages, with each such linkage bonding a polyorganosiloxane block and a hydrocarbyl block, and also including a polar functionality.

Owner:HEIDELBERG DIGITAL +1

Method of washing a surface

ActiveUS20080103083A1Efficient washingQuantity minimizationBiocideOrganic detergent compounding agentsAliphatic hydrocarbonSURFACTANT BLEND

A method of washing a surface includes the step of providing a cleaning formulation including a surfactant composition including a first surfactant, a second surfactant, and a polyalkylene glycol. The first surfactant has the general formula: R1—O-(A)mH. R1 is an aliphatic hydrocarbon having from 8 to 11 carbon atoms, A is an alkyleneoxy group having from 2 to 5 carbon atoms, and m is a positive number. The second surfactant has the general formula: R2—O—(B)nH. R2 is an aliphatic hydrocarbon having from 12 to 14 carbon atoms, B is an alkyleneoxy group having from 2 to 5 carbon atoms, and n is a positive number. The polyalkylene glycol is present in an amount of from 3 to 20 parts by weight. The method also includes providing a rinse formulation, applying the cleaning formulation to the surface, and applying the rinse formulation to the surface.

Owner:BASF AG

Cleaning method and apparatus

ActiveUS8377222B2Improve surface wettingExtension of timeSpraying apparatusHollow article cleaningInternal pressureCleaning methods

A method for cleaning an interior surface of a processing equipment using a treatment liquid, the processing equipment including a pipe section defining pipe section first and second ends, the pipe section defining a pipe section volume delimited by the pipe section first and second ends, the pipe section being initially at an initial internal pressure. The method includes introducing a predetermined volume of the treatment liquid, the predetermined volume being substantially smaller than the pipe section volume circulating the predetermined volume of the treatment liquid through the pipe section by simultaneously reducing an internal pressure within the pipe section at a location substantially adjacent the pipe section second end and increasing an internal pressure within the pipe section at a location substantially adjacent the pipe section first end.

Owner:LAUZON NORMAND

Method for immobilizing nucleic acids

InactiveUS20040023226A1Strong signalImprove surface wettingBioreactor/fermenter combinationsBiological substance pretreatmentsImmobilized Nucleic AcidsAqueous solution

The invention relates to a method for immobilizing nucleic acids on one of the surfaces of a non-porous organic polymeric material which does not carry any primary and / or secondary amine groups. The inventive method comprises the following steps: (a) an aqueous solution containing a nucleic acid as well as a dissolved salt is prepared, whereby the cation of the salt is selected from the group comprised of sodium, magnesium and of mixtures of these cations; (b) the solution mentioned in step (a) is brought into contact with the surface of the polymeric material, and; (c) the surface of the polymeric material, which is in contact with the solution, is irradiated with UV light after step (b) or simultaneously thereto.

Owner:VARIOM BIOTECH

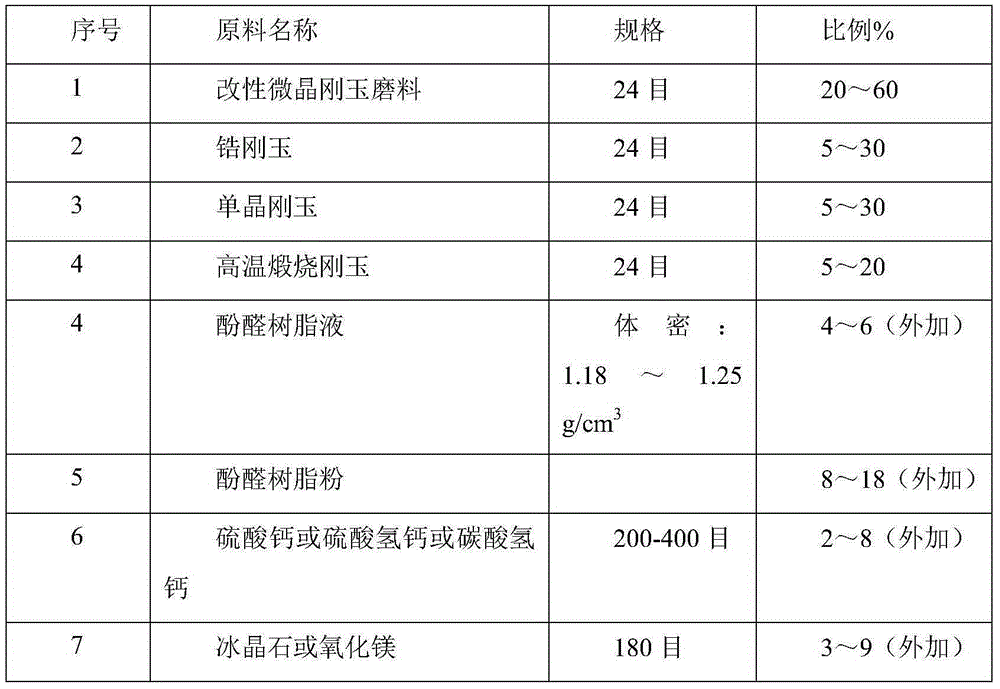

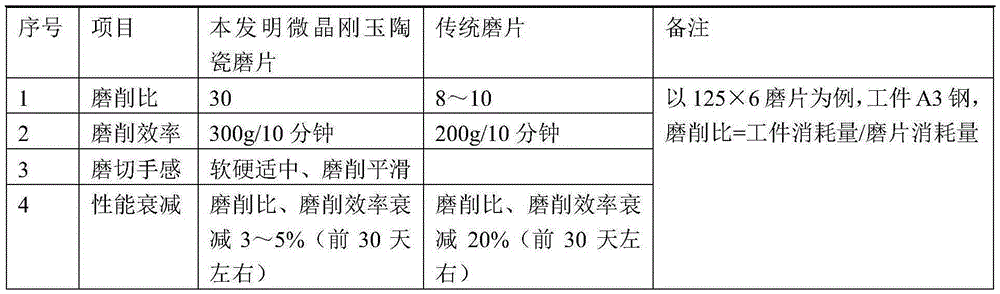

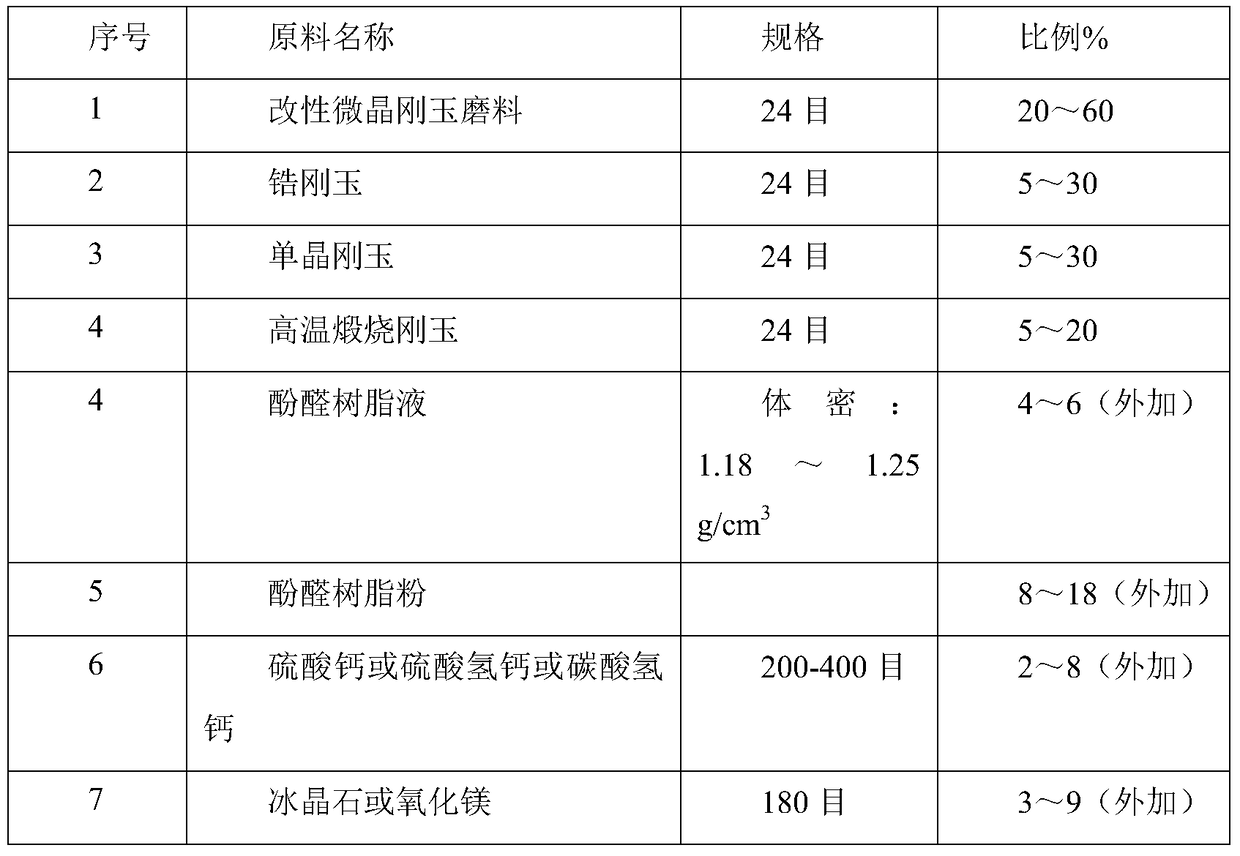

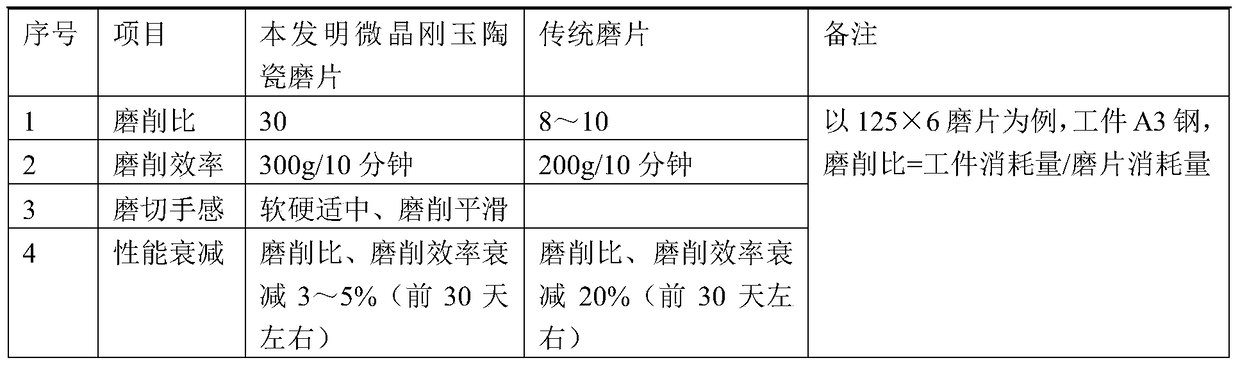

A microcrystalline fused alumina ceramic abrasive disc and a method for preparing the same

InactiveCN106607770AImprove surface wettingImprove gripAbrasion apparatusGrinding devicesPolymer scienceAlumina zirconia

The invention relates to the technical field of grinding material and grinding tool preparation and in particular provides a high-performance microcrystalline fused alumina ceramic abrasive disc and a method for preparing the same. The microcrystalline fused alumina ceramic abrasive disc contains, in percentage by weight, 20-60% of modified microcrystalline fused alumina abrasive materials, 5-30% of fused alumina zirconia, 5-30% of monocrystalline fused alumina, 5-20% of high temperature calcinated fused alumina, 4-6% of phenolic resin liquid, 8-18% of phenolic resin powder, 2-8% of filler, and 3-9% of an additive. The preparation method comprises the steps of preparing phenolic resin modified liquid, preparing modified microcrystalline fused alumina abrasive materials, and performing shaping and hardening. The microcrystalline fused alumina ceramic abrasive disc has the advantages of low manufacture cost and long service life; the binding force between resin and abrasive material particle is great and the holding force applied to abrasive material particles by resin is great, so that the cutting and grinding efficiency of the abrasive disc are improved greatly.

Owner:南京诺之瑞思商贸有限公司

Orthopaedic joints providing enhanced lubricity

ActiveUS9585757B2Increase surface lubricityWear minimizationJoint implantsProsthesisProsthetic joint component

The present disclosure provides, among other things, prosthetic joint components having textured surface(s) for improving lubrication and increasing the useful life of the prosthetic joint components. The textured surface includes solid features configured to stably contain a biological fluid or a synthetic biological fluid therebetween or therewithin for a non-zero residence time.

Owner:MASSACHUSETTS INST OF TECH

Method for enhancing inner protection film hydrophilicity of polaroid

The invention relates to a method for increasing the hydrophilicity of a protecting film in a polaroid. In the process of alkali treatment of the protecting film, the method adds a quaternary ammonium salt cation surface active agent with the following chemical structural formula. In the formula, R1, R2, R3 and R4 are alkyl chains, wherein at least one carbon chain is less than or equal to 2, and at least one carbon chain is between 12 and 20; X is one of F, Cl, Br and I of halogen elements; the addition of the surface active agent is 0.001-1 percent; the concentration of the treatment fluid (alkali solution) is from 2-12 percent; the treatment temperature is from 26-45 DEG C; and the treatment time is from 60-110s. On the premise of guaranteeing the treatment effect of the hydrophilicity, the addition of the surface active agent can reduce the concentration of the alkali solution, reduce the treatment temperature (and / or shorten the treatment time); and simultaneously, the uniformity of the treatment is obviously increased, thus, the production cost is lowered, and the pressure of environmental protection treatment is lightened.

Owner:SHENZHEN SAPO PHOTOELECTRIC

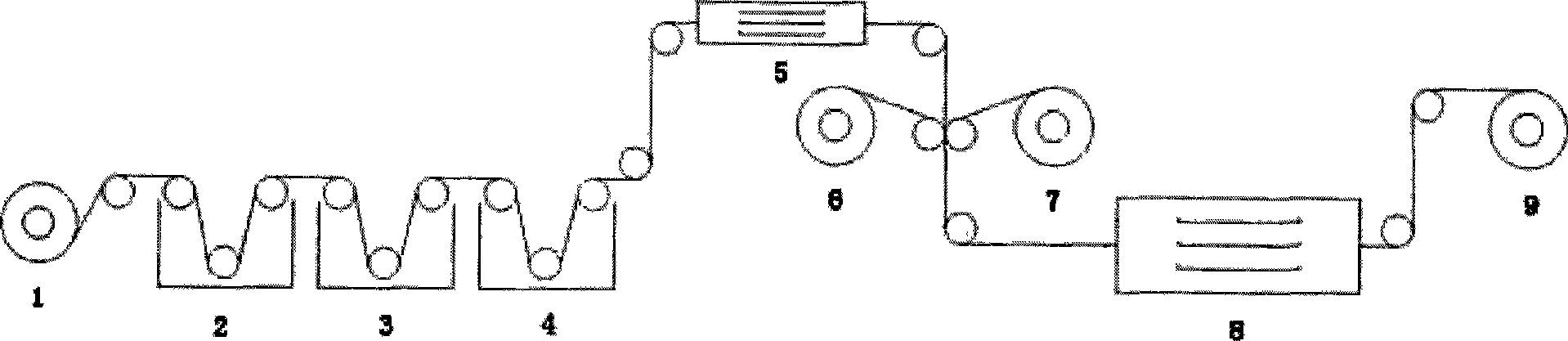

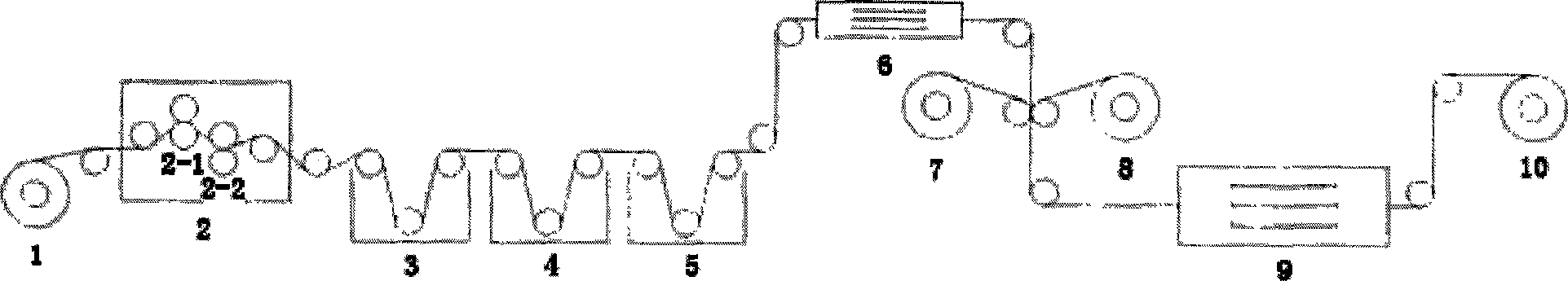

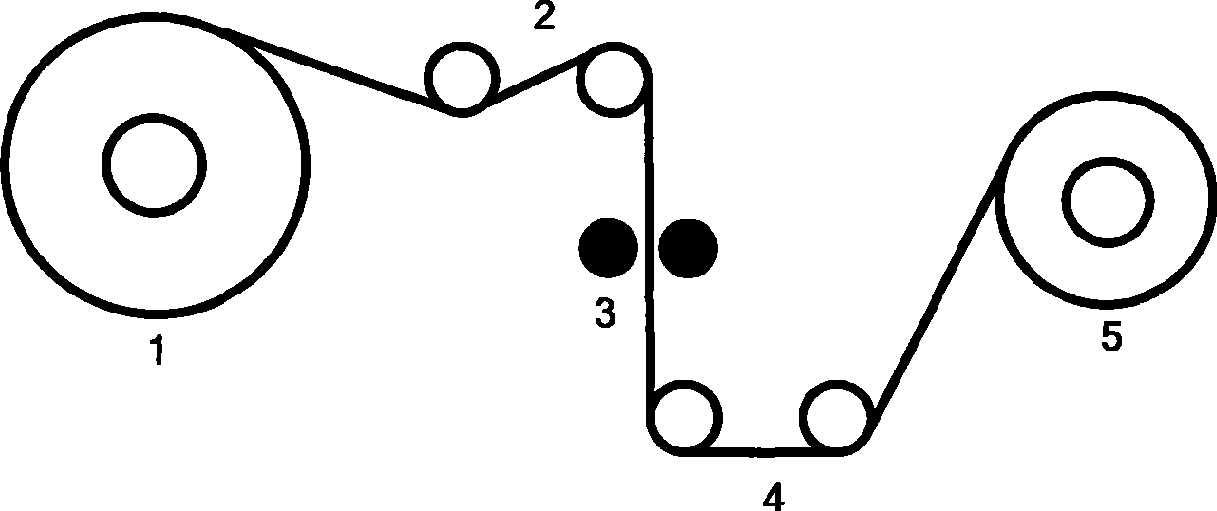

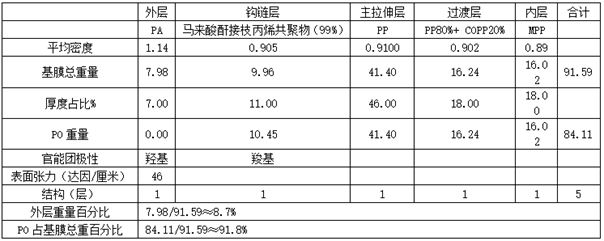

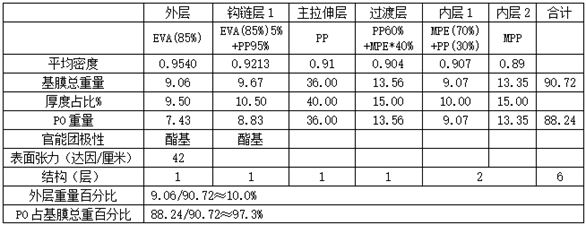

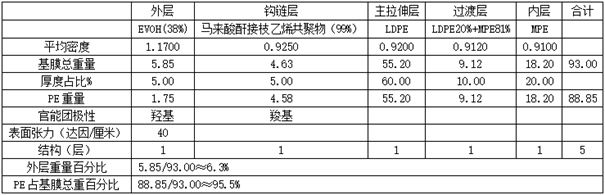

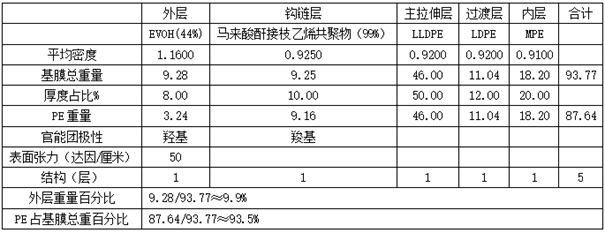

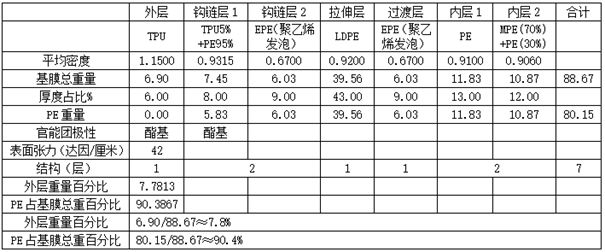

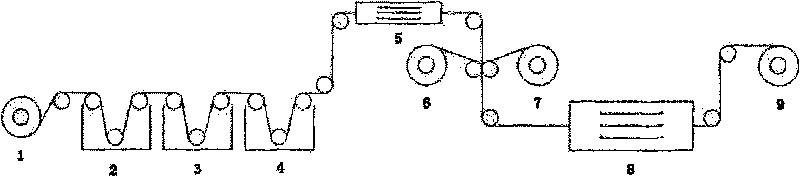

Biaxially oriented polypropylene base film with high surface energy

PendingCN114407462AImprove adhesionHigh surface energySynthetic resin layered productsPolymer sciencePolyolefin

The invention relates to a biaxially oriented polypropylene base film with high surface energy, which is prepared from the following at least five layers of structures through co-extrusion and biaxially oriented stretching processes, and the five layers of structures sequentially comprise an outer layer, a hook chain layer, a main stretching layer, a transition layer and an inner layer in the thickness direction of the base film, the high surface adhesive force between the base film and other films or layers can be improved in a chemical bond mode, and the hook chain layer is transition of polarity and compatibility between the main stretching layer and an outer layer material. The main stretching layer is a functional layer undertaking a main stretching task in a two-way stretching processing process; the transition layer is used for transition of melting temperature between the main stretching layer and the inner layer material; and the inner layer is a heat sealing layer. The base film with high surface energy is obtained by endowing the surface layer with polarity, so that the high adhesive force of the surface of the PE base material is realized. Through the design that the weight of the polyolefin is greater than or equal to 90% of the total weight of the base film, the environment-friendly requirements that the product is easy to recycle and easy to use at a high value are met.

Owner:KUSN JIAPU PACKING MATERIAL

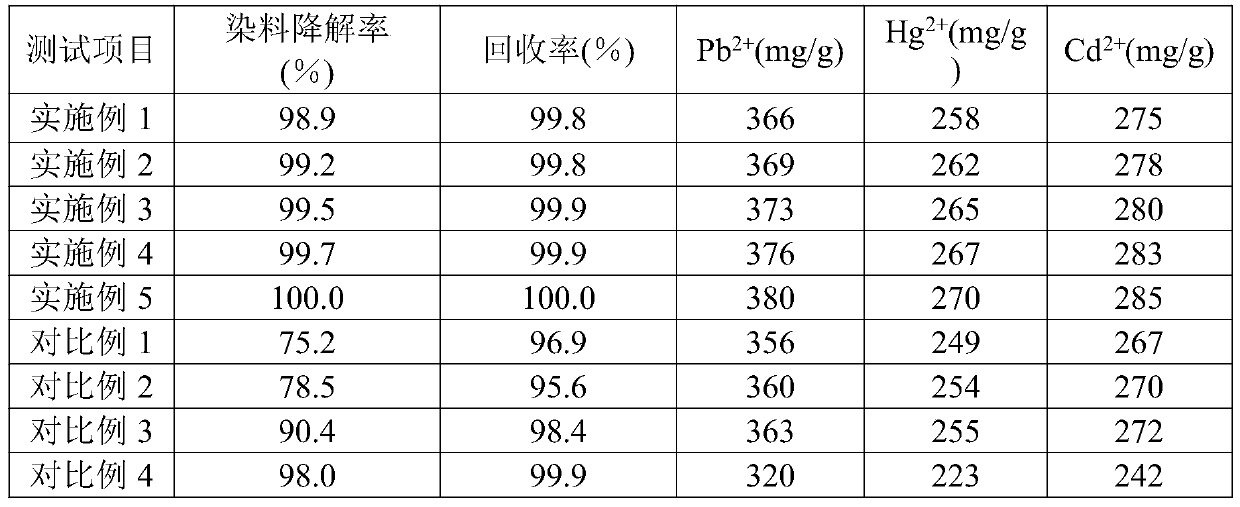

Membrane material for industrial wastewater treatment

InactiveCN111282552ASimple processEasy to operateSemi-permeable membranesMembranesIndustrial waste waterTriazine

The invention discloses a membrane material for industrial wastewater treatment. The membrane material is characterized by being prepared from the following polymerizable monomers in parts by weight through free radical polymerization: 3-6 parts of vinyl modified boronized black phosphorus quantum dots, 8-12 parts of vinyl-terminated hyperbranched poly (amine-ester) and 1-3 parts of beta-phenyl acryloyl chloride modified 2, 4, 6-tri (4-aminophenyl)-1, 3, 5-triazine. The invention also discloses a preparation method of the membrane material for industrial wastewater treatment. The membrane material for industrial wastewater treatment disclosed by the invention is good in treatment effect on industrial wastewater containing heavy metal ions, high in efficiency, excellent in mechanical property, corrosion resistance and pollution resistance, and particularly high in capacity of catalyzing decomposition of organic matters in the wastewater and adsorbing and separating the heavy metal ionsin the wastewater.

Owner:周青英

Lubricant for wall reduction and drawing of titanium alloy pipe and using method thereof

The invention discloses a lubricant for wall reduction and drawing of a titanium alloy pipe and a using method thereof. The lubricant is made by uniformly mixing and stirring the following raw materials in percentage by weight: 85-96% of chlorinated paraffin and 4-15% of BN (Boron Nitride). The using method of the lubricant comprises the following steps of: cleaning the titanium alloy pipe, carrying out heat treatment on the titanium alloy pipe after baking, respectively smearing a layer of the lubricant on the inner and the outer surfaces of the titanium alloy pipe after the heat treatment, rolling one end of the titanium alloy pipe, putting a moving core head in the titanium alloy pipe and carrying out the wall reduction and the drawing to obtain the titanium alloy pipe. The lubricant disclosed by the invention has the characteristics of capability of continuous self-lubrication, good lubricant adhering effect, simplicity in composition proportioning, easiness in cleaning and removing, environmental protection, no pollution and the like. By adopting the lubricant disclosed by the invention, the titanium alloy pipe drawing production efficiency can be effectively increased.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of preparation method of microcrystalline corundum ceramic grinding disc

InactiveCN106607770BImprove surface wettingImprove gripAbrasion apparatusGrinding devicesPolymer scienceAlumina zirconia

The invention relates to the technical field of grinding material and grinding tool preparation and in particular provides a high-performance microcrystalline fused alumina ceramic abrasive disc and a method for preparing the same. The microcrystalline fused alumina ceramic abrasive disc contains, in percentage by weight, 20-60% of modified microcrystalline fused alumina abrasive materials, 5-30% of fused alumina zirconia, 5-30% of monocrystalline fused alumina, 5-20% of high temperature calcinated fused alumina, 4-6% of phenolic resin liquid, 8-18% of phenolic resin powder, 2-8% of filler, and 3-9% of an additive. The preparation method comprises the steps of preparing phenolic resin modified liquid, preparing modified microcrystalline fused alumina abrasive materials, and performing shaping and hardening. The microcrystalline fused alumina ceramic abrasive disc has the advantages of low manufacture cost and long service life; the binding force between resin and abrasive material particle is great and the holding force applied to abrasive material particles by resin is great, so that the cutting and grinding efficiency of the abrasive disc are improved greatly.

Owner:南京诺之瑞思商贸有限公司

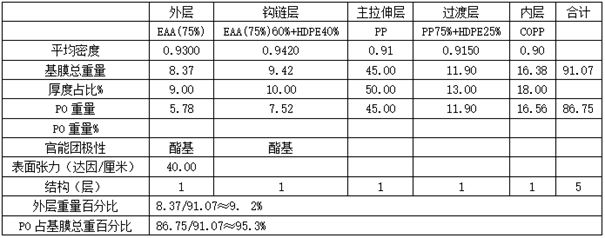

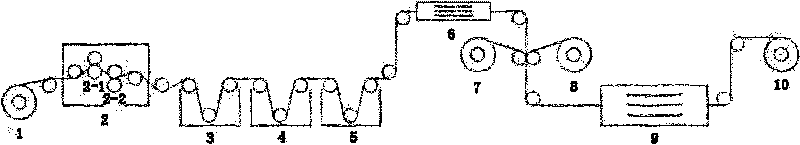

Biaxially oriented polyethylene-based film with high surface energy

PendingCN114407461AImprove adhesionHigh surface energySynthetic resin layered productsPolymer scienceBoPET

The invention relates to a biaxially oriented polyethylene base film with high surface energy, which is prepared from the following at least five layers of structures through co-extrusion and biaxially oriented stretching processes: the five layers of structures sequentially comprise an outer layer, a hook chain layer, a main stretching layer, a transition layer and an inner layer in the thickness direction of the base film, the outer layer is a high-surface-energy layer, and the inner layer is a high-surface-energy layer; the high surface adhesive force between the base film and other films or layers can be improved in a chemical bond mode, and the hook chain layer is transition of polarity and compatibility between the main stretching layer and an outer layer material. The main stretching layer is a functional layer undertaking a main stretching task in a two-way stretching processing process; the transition layer is used for transition of melting temperature between the main stretching layer and the inner layer material; and the inner layer is a heat sealing layer. The base film with high surface energy is obtained by endowing the surface layer with polarity, so that the high adhesive force of the surface of the PE base material is realized. Through the design that the weight of the polyethylene is greater than or equal to 90% of the total weight of the base film, the environment-friendly requirements that the product is easy to recover and recycle are met.

Owner:江苏彩华包装集团整体包装科技有限公司

Method for enhancing inner protection film hydrophilicity of polaroid

ActiveCN101424764BReduce concentrationImprove hydrophilicityPolarising elementsHalogenTherapeutic effect

The invention relates to a method for increasing the hydrophilicity of a protecting film in a polaroid. In the process of alkali treatment of the protecting film, the method adds a quaternary ammoniumsalt cation surface active agent with the following chemical structural formula. In the formula, R1, R2, R3 and R4 are alkyl chains, wherein at least one carbon chain is less than or equal to 2, andat least one carbon chain is between 12 and 20; X is one of F, Cl, Br and I of halogen elements; the addition of the surface active agent is 0.001-1 percent; the concentration of the treatment fluid (alkali solution) is from 2-12 percent; the treatment temperature is from 26-45 DEG C; and the treatment time is from 60-110s. On the premise of guaranteeing the treatment effect of the hydrophilicity,the addition of the surface active agent can reduce the concentration of the alkali solution, reduce the treatment temperature (and / or shorten the treatment time); and simultaneously, the uniformityof the treatment is obviously increased, thus, the production cost is lowered, and the pressure of environmental protection treatment is lightened.

Owner:SHENZHEN SAPO PHOTOELECTRIC

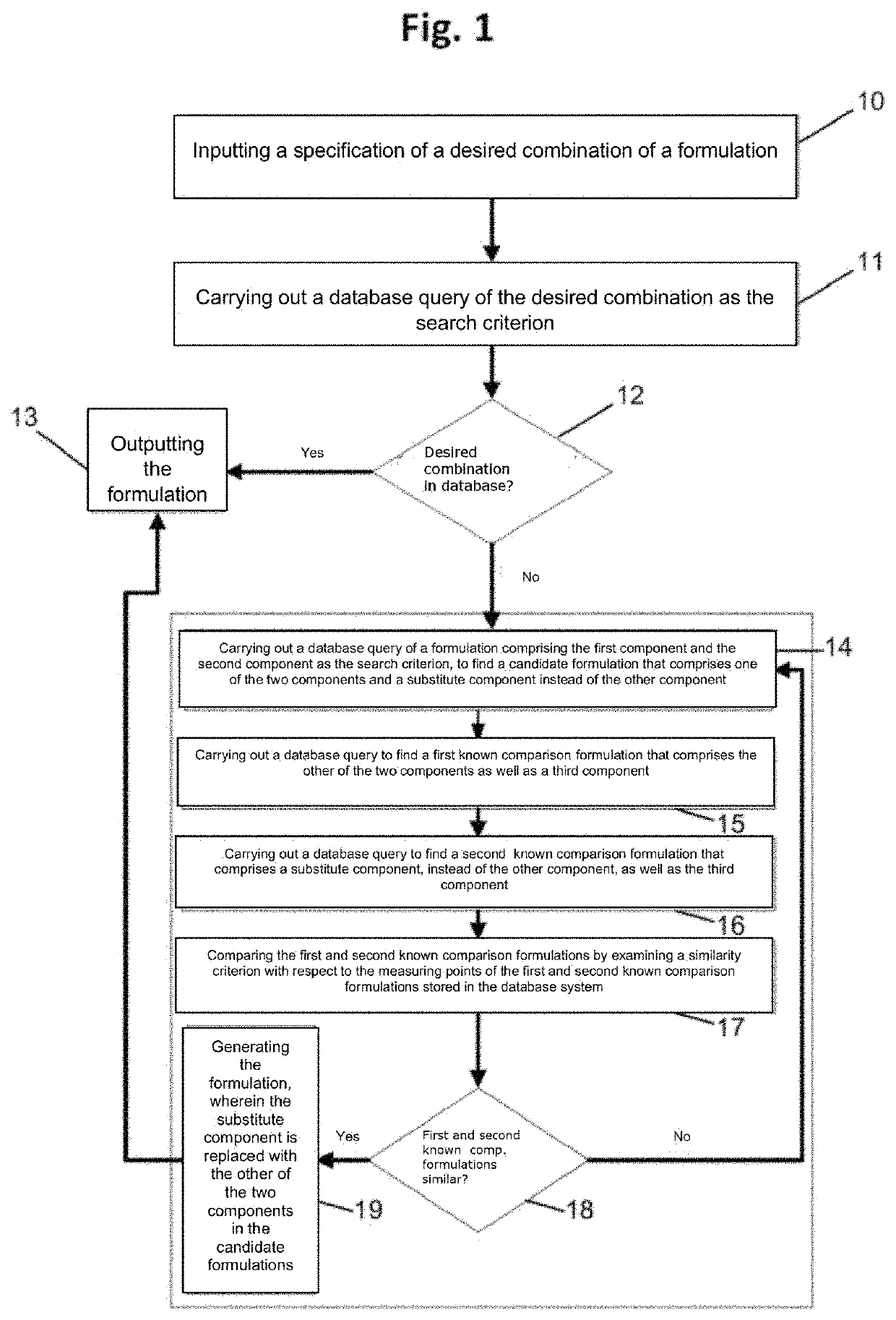

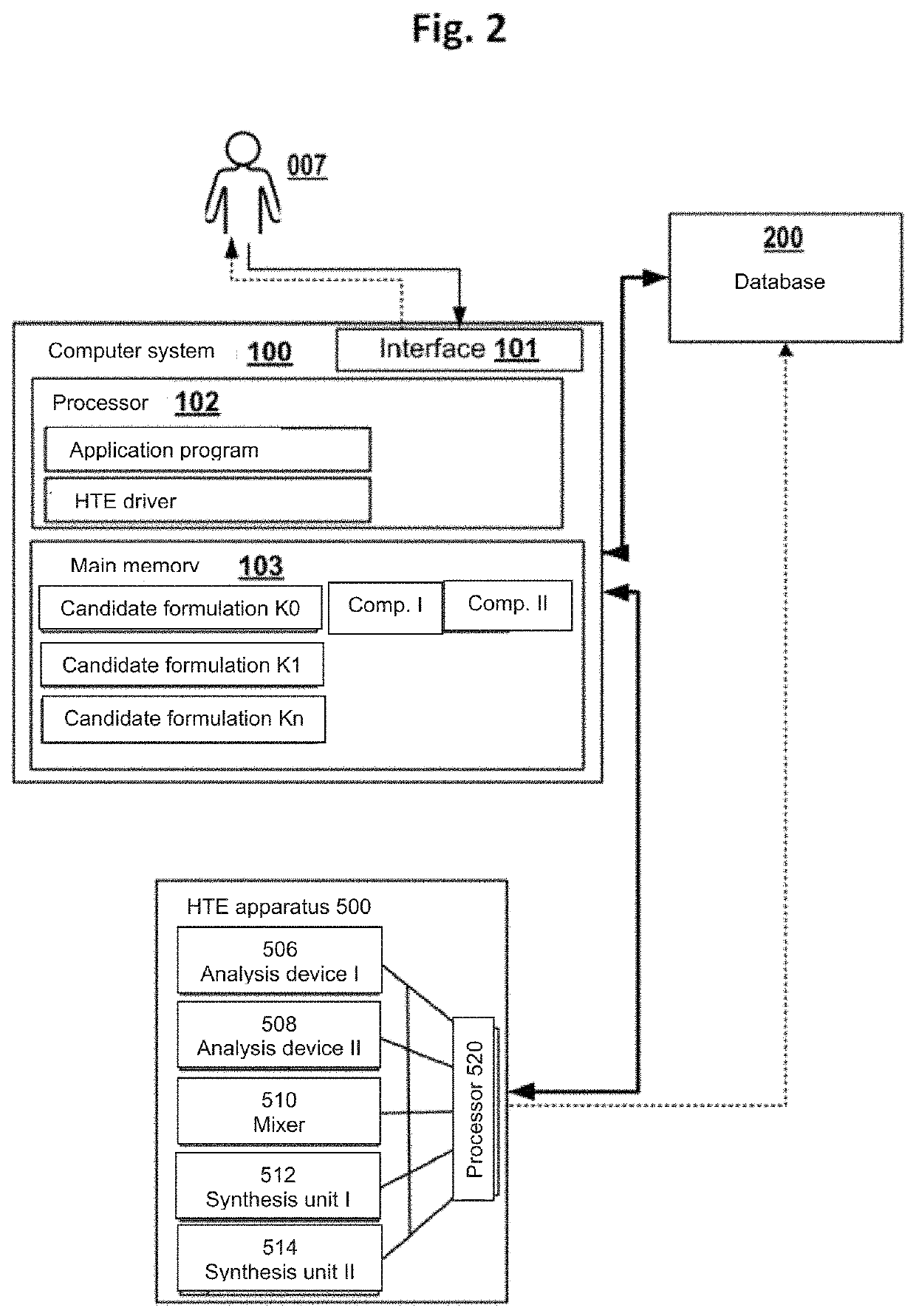

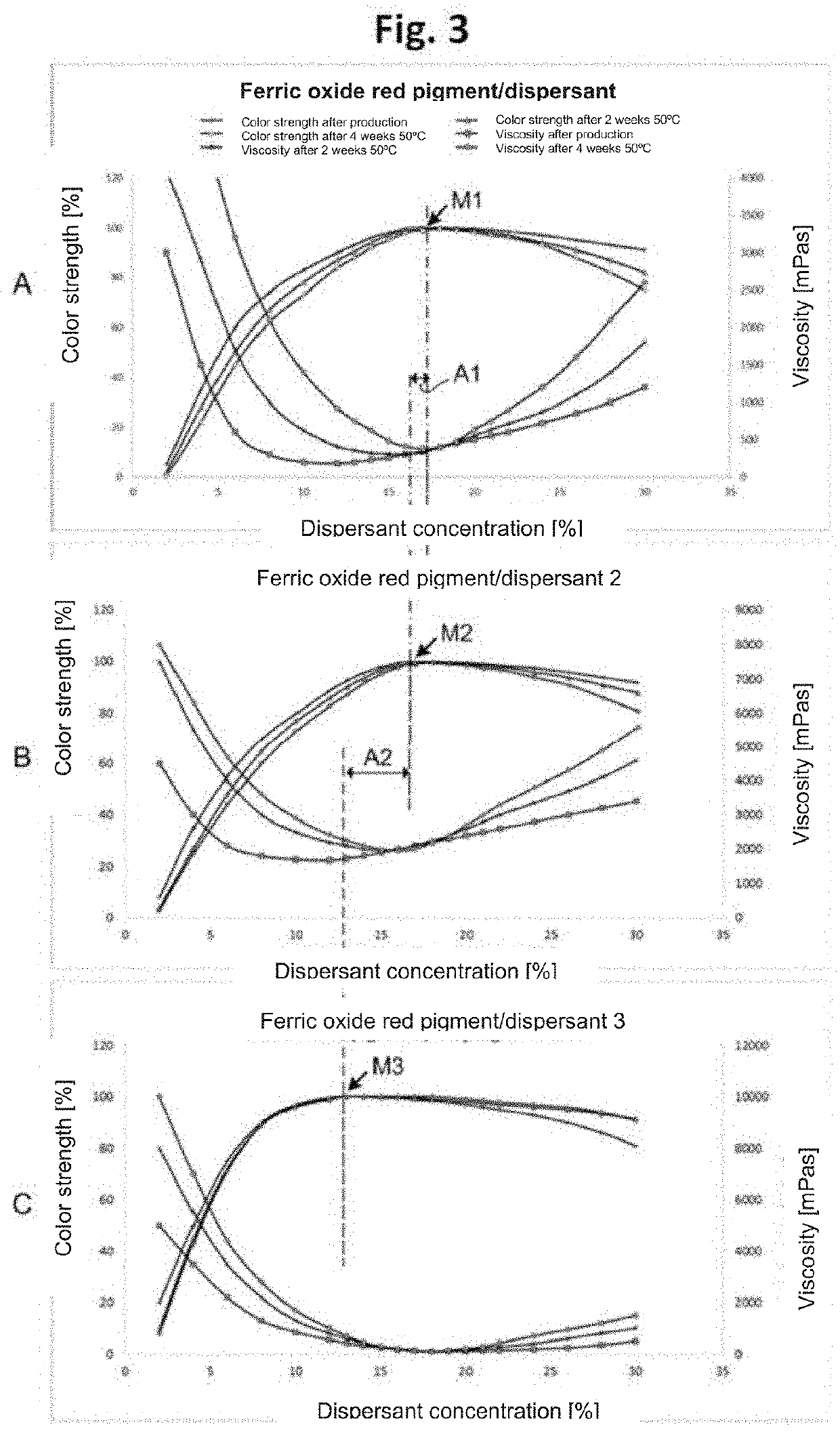

Method for generating a composition for paints,varnishes, printing inks, grinding resins, pigment concentrates or other coating substances

PendingUS20220228011A1Time-saving and cost-effectiveLow viscosityChemical property predictionInksDatabase queryEngineering

The method includes inputting a specification of a desired combination of a first component and a second component of a composition, wherein the components are a solid and a dispersant, via a user interface of a computer system; carrying out a database query with the desired combination of the first component and the second component as the search criterion, wherein in the case where the database query supplies a known composition that meets the search criterion, the known composition is output, wherein in the opposite case, a further database query of a composition including the first component and the second component, serving as the search criterion, is carried out to find a candidate composition that includes one of the two components as well as a substitute component instead of the other component; and carrying out further steps for generating the formulation and outputting the composition.

Owner:EVONIK OPERATIONS GMBH

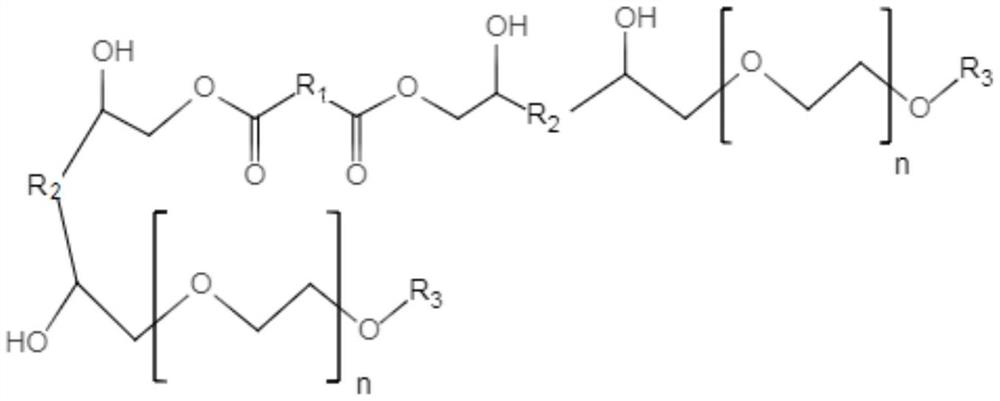

Non-ionic reaction type water-based paint hyperdispersant and preparation method thereof

ActiveCN114349952AUniform and stable dispersionImprove water resistanceEpoxy resin coatingsPtru catalystPolyol

The invention relates to the technical field of water-based paint, in particular to a nonionic reaction type water-based paint hyperdispersant and a preparation method thereof.The preparation method comprises the following steps that 1, in the presence of a solvent and a catalyst, a binary epoxy compound reacts with mono-substituent polyoxyethylene ether to prepare an intermediate 1; 2, reacting the intermediate 1 obtained in the step 1 with a dicarboxylic acid compound in a solvent to prepare a mixture 2; 3, the mixture 2 obtained in the step 2 reacts with a unit or polyol compound in a solvent under the action of a catalyst, the solvent is distilled out after the reaction, quantitative deionized water is added according to the designed solid content after cooling, cooling and discharging are conducted, and the non-ionic reaction type water-based paint hyperdispersant is obtained. The hyperdispersant prepared by the preparation method disclosed by the invention not only can stably and uniformly disperse solid pigments and fillers in a coating, but also can improve the water resistance and salt spray resistance of a water-based coating and the adhesion performance of the water-based coating to a metal base material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

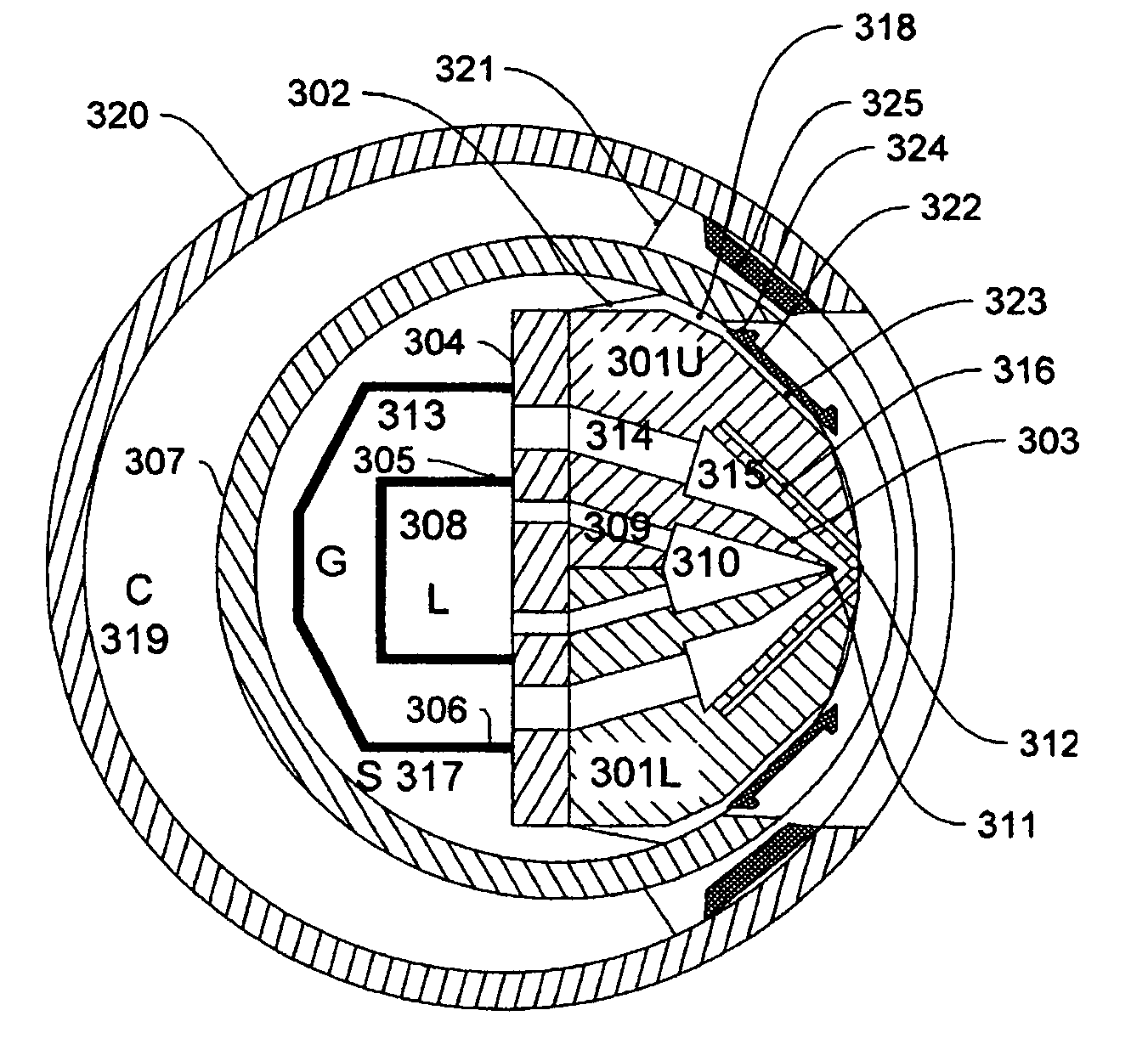

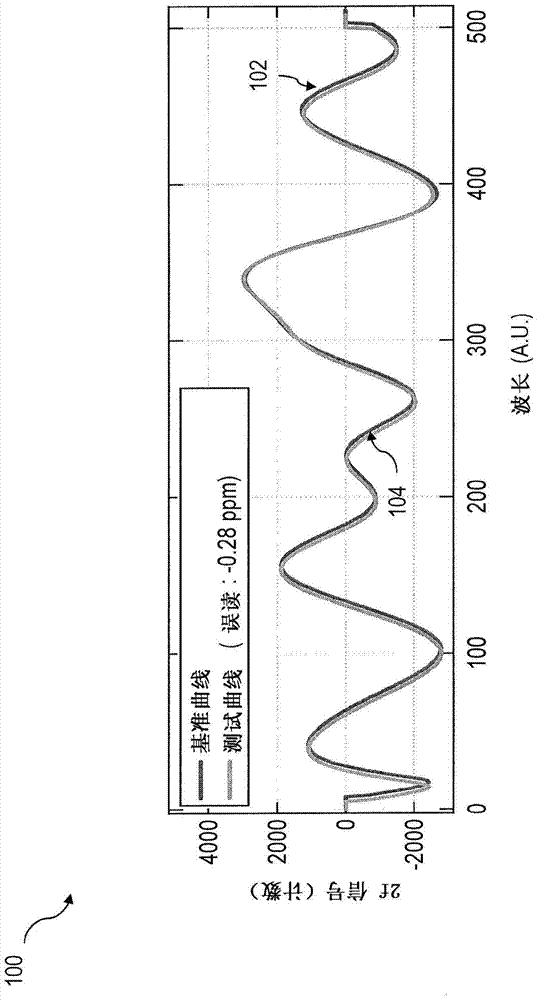

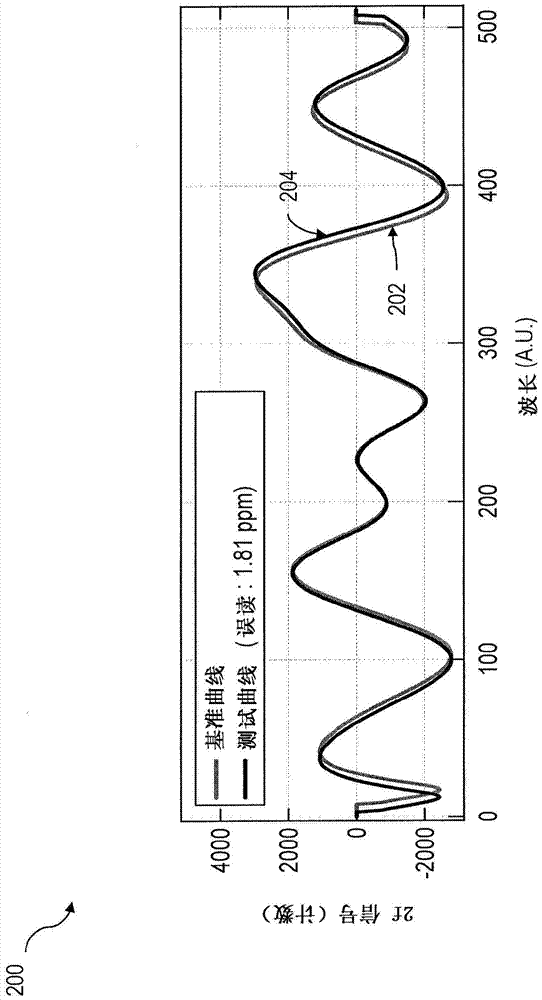

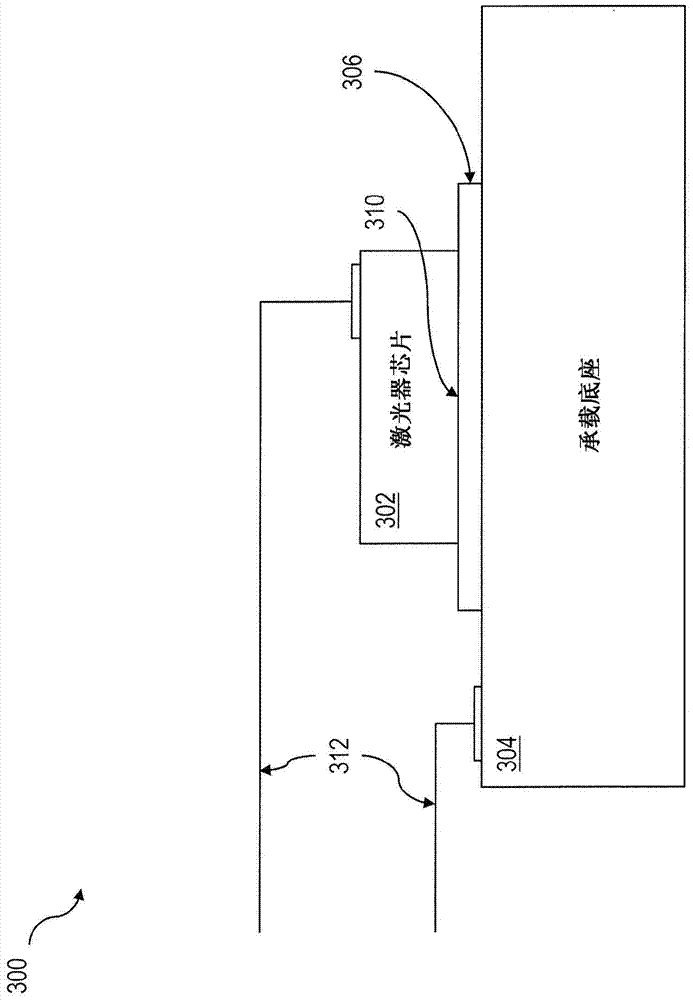

Diode Lasers Mounted with Integral Diffusion Barriers

ActiveCN103782459BReduce usageImprove continuityLaser detailsSemiconductor/solid-state device detailsTitanium nitrideGadolinium

The first contact (310) surface of the semiconductor laser chip (302) is formed to have a surface roughness selected to have a maximum peak-to-valley height that is substantially less than the thickness of the diffusion barrier layer. A diffusion barrier layer comprising a non-metallic conductive compound and having the thickness of the barrier layer may be applied to the first contact surface, and the solder composition (306) along the The first contact surface solders the semiconductor laser chip to the carrier mount (304), at the threshold temperature, dissolution of the barrier layer into the solder composition occurs. The diffusion barrier thus remains continuous. The non-metal conductive compound includes at least one of titanium nitride, titanium oxynitride, tungsten nitride, cerium oxide and cerium gadolinium oxynitride.

Owner:ENDRESS + HAUSER OPTICAL ANALYSIS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com