Diode Lasers Mounted with Integral Diffusion Barriers

A technology of lasers and semiconductors, applied in the direction of semiconductor lasers, semiconductor devices, lasers, etc., can solve the problems of trace gas analyte identification and quantification critical errors, and achieve good solder joint continuity and good surface wetting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

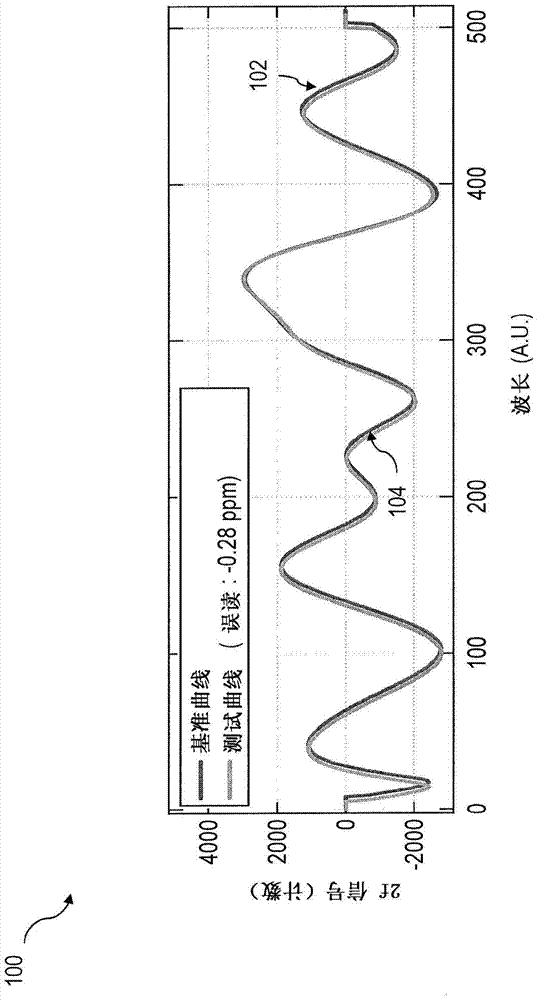

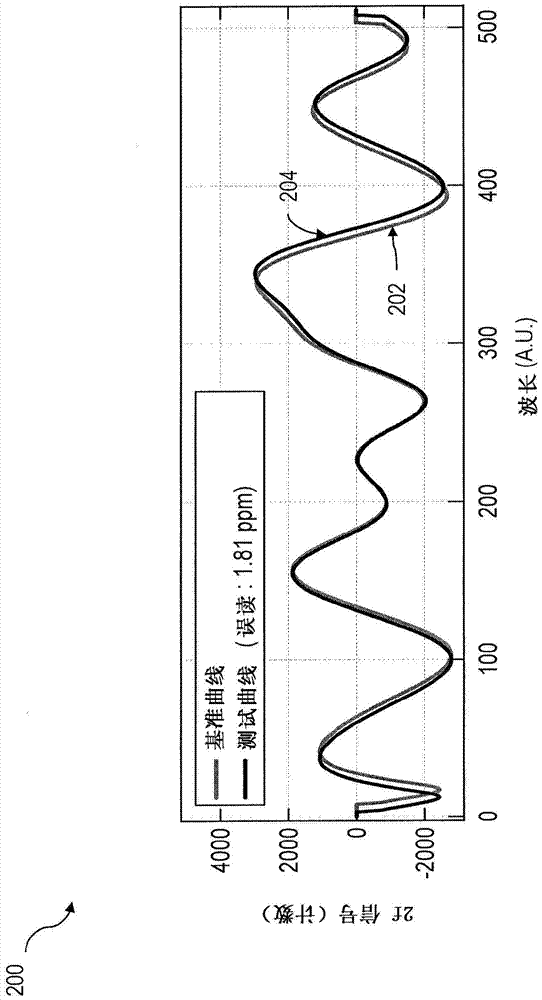

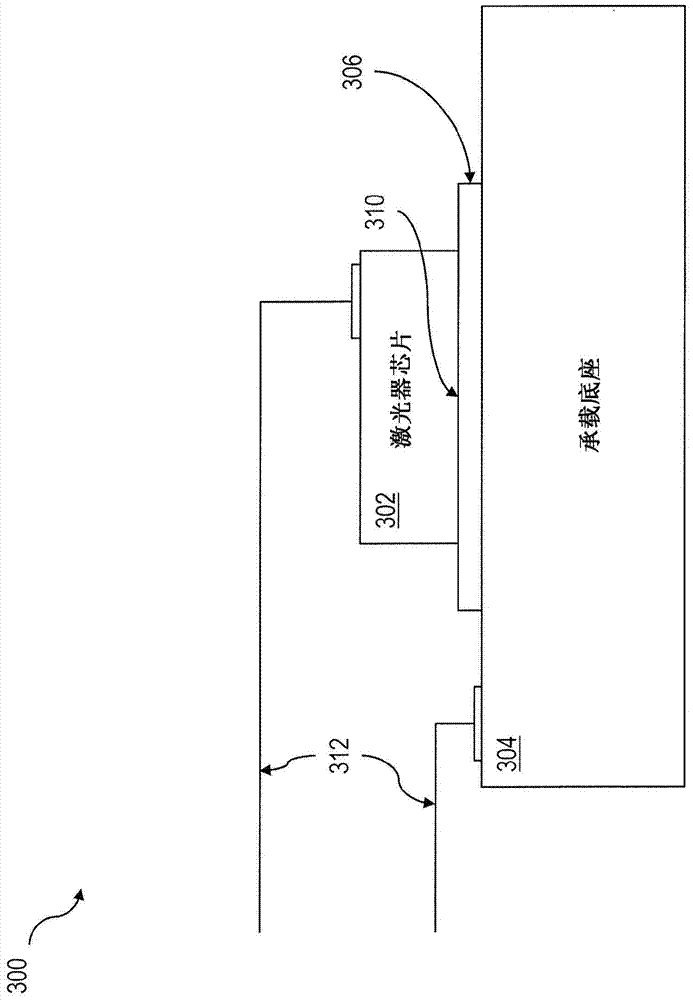

[0032] Experimental data show that in a laser absorption spectrometer utilizing a scannable or tunable laser source, a change in laser emission wavelength as small as 1 picometer (pm) or less between spectral scans, in its initial calibrated state, can significantly change the Determination of trace gas concentrations with respect to measurements obtainable with spectrum analyzers. An example of spectral laser spectroscopy using difference spectroscopy is described in commonly owned US Patent No. 7,704,301, the disclosure of which is incorporated herein in its entirety. Other experimental data indicate that the detection and quantification of analytes designed for low concentrations (such as hydrogen sulfide (H 2 S) on the order of parts per million (ppm)) and tunable diode laser-based analyzers employing harmonic (e.g. 2f) wavelength-modulated spectral subtraction, due to constant injection current and constant temperature (e.g., A laser output shift as small as 20 picometer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com