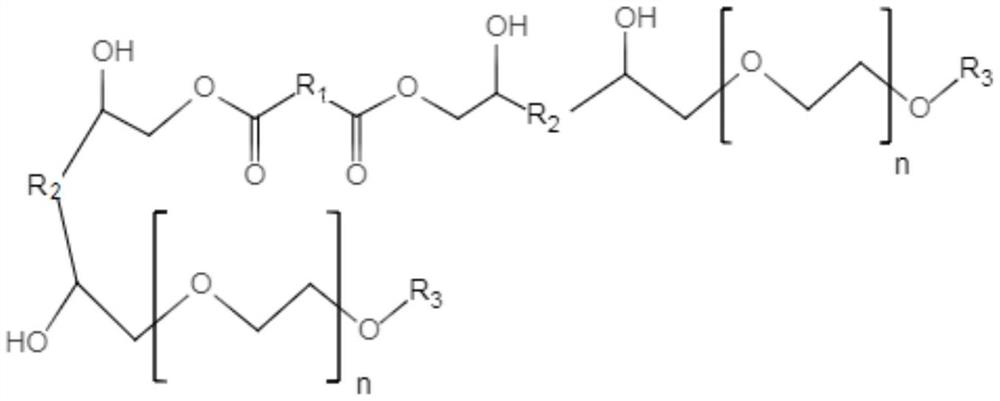

Non-ionic reaction type water-based paint hyperdispersant and preparation method thereof

A non-ionic reactive, water-based coating technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of low metal substrate adhesion, insufficient salt spray resistance, poor long-term stability, etc., to achieve enhanced surface moisturization Wet, increase the crosslink density, improve the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mix 1 mol of dehydrated oleic acid polyoxyethylene ether with 3000 ml of dioxane solvent, add 2 g of boron trifluoride etherate complex, and add 1 mol of bisphenol F epoxy resin with stirring at 55 ° C. (referring to the amount of the substance containing the structural unit of the bisepoxide group in the bisphenol F epoxy resin), the reaction temperature was controlled at 110° C., and the reaction was carried out for 50 minutes to obtain the intermediate 1.

[0038] (2) Add 0.35 mol of glutaric acid and 0.05 mol of p-toluenesulfonic acid to the product of step (1), and react at 150°C for 120 min to obtain a mixture 2 including intermediate 2 and intermediate 1.

[0039](3) Add 0.05mol benzyl alcohol and 0.1mol ethylene glycol to mixture 2, react at 120°C for 30min, remove the solvent by rotary evaporation, add deionized water according to the solid content of 40% after cooling down, and cool and discharge to obtain 40% solid content Hyperdispersant products.

[00...

Embodiment 2

[0042] (1) Mix 1 mol of dehydrated castor oil-based polyoxyethylene ether with 3000 ml of xylene solvent, add 2 g of boron trifluoride etherate complex, and add 1.2 mol of bisphenol A epoxy resin with stirring at 55° C. (Referring to the amount of the substance containing the structural unit of the bisepoxide group in the bisphenol A epoxy resin), the reaction temperature is controlled at 40° C., and the reaction is carried out for 120 minutes to obtain the intermediate 1.

[0043] (2) Add 0.4 mol of adipic acid and 0.05 mol of p-toluenesulfonic acid to the product of step (1), and react at 100°C for 60 minutes to obtain a mixture 2 including intermediate 2 and intermediate 1.

[0044] (3) Add 0.1mol benzyl alcohol to the mixture 2, react at 80°C for 120min, remove the solvent by rotary evaporation, add deionized water according to the solid content of 15% after cooling down, and cool and discharge to obtain a hyperdispersant product with a solid content of 15%.

Embodiment 3

[0046] (1) Mix 1mol of dehydrated polyoxyethylene lauryl ether with 3000ml of ethyl acetate solvent, add 2g of triphenylphosphine, and add 1,4-butanediol diglycidyl ether while stirring at 55°C 0.8mol, the reaction temperature was controlled at 60°C, and the reaction was carried out for 30 minutes to obtain intermediate 1.

[0047] (2) Add 0.36 mol of phthalic acid and 0.05 mol of p-toluenesulfonic acid to the product of step (1), and react at 180°C for 30 minutes to obtain a mixture 2 including intermediate 2 and intermediate 1.

[0048] (3) Add 0.05mol isooctyl alcohol to the mixture 2, react at 100°C for 150min, remove the solvent by rotary evaporation, add deionized water according to 90% solid content after cooling down, and cool and discharge to obtain a hyperdispersant product with 90% solid content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com