Membrane material for industrial wastewater treatment

A technology of industrial wastewater and membrane materials, which is applied in the direction of adsorption water/sewage treatment, light water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of consumption of amino, no catalytic decomposition of toxic and harmful organic substances, and reduce the treatment of heavy metal ions ability and other issues, to achieve the effect of improving description, improving mechanical properties and performance stability, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

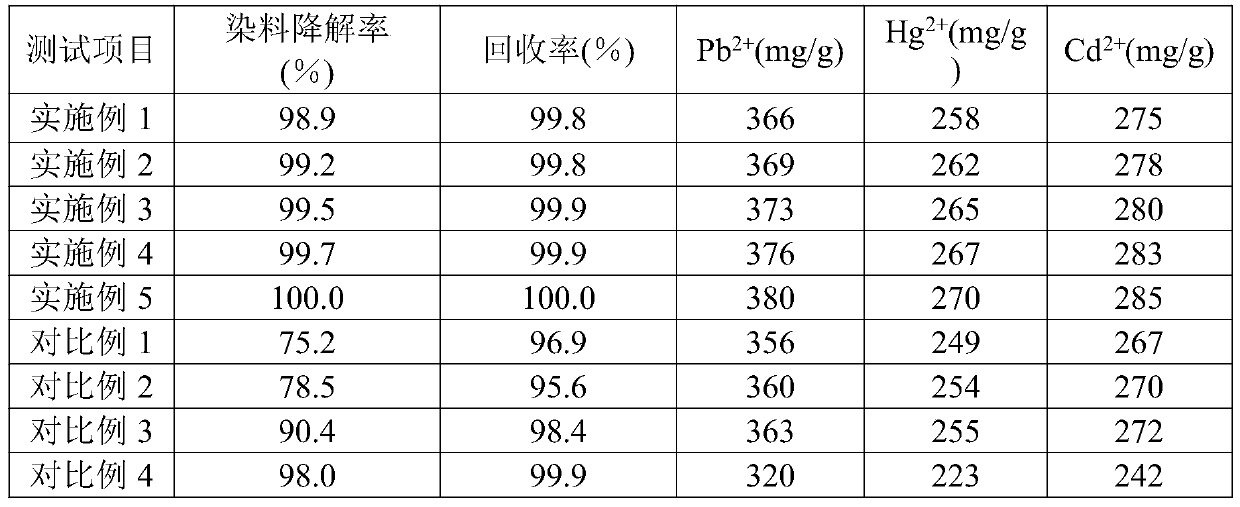

Examples

Embodiment 1

[0034] A membrane material for industrial wastewater treatment, formed by free radical polymerization of the following polymerizable monomers in parts by weight: 3 parts of vinyl-modified boronized black phosphorus quantum dots, vinyl-terminated hyperbranched poly(amine-ester ) 8 parts, β-phenylacryloyl chloride modified 2,4,6-tris(4-aminophenyl)-1,3,5-triazine 1 part.

[0035] The preparation method of the vinyl-modified black phosphorus boride quantum dots comprises the following steps:

[0036] Step S1, put black phosphorus quantum dots, ammonium pentaborate, Tween 20, and ethanol in a polytetrafluoroethylene reaction kettle, keep warm at 150°C for 8 hours, cool to room temperature, remove ethanol by rotary evaporation, and then place in water Disperse, centrifuge, and dry to constant weight at 85°C to obtain boronized black phosphorus quantum dots; the mass ratio of the black phosphorus quantum dots, ammonium pentaborate, Tween 20, and ethanol is 1:0.05:0.1:5;

[0037] St...

Embodiment 2

[0042] A membrane material for industrial wastewater treatment, formed by free radical polymerization of the following polymerizable monomers in parts by weight: 4 parts of vinyl-modified boronized black phosphorus quantum dots, vinyl-terminated hyperbranched poly(amine-ester ) 9 parts, β-phenylacryloyl chloride modified 2,4,6-tris(4-aminophenyl)-1,3,5-triazine 1.5 parts.

[0043] The preparation method of the vinyl-modified black phosphorus boride quantum dots comprises the following steps:

[0044] Step S1, put black phosphorus quantum dots, ammonium pentaborate, Tween 20, and ethanol in a polytetrafluoroethylene reaction kettle, keep warm at 155°C for 9 hours, cool to room temperature, remove ethanol by rotary evaporation, and then place in water Disperse, centrifuge, and dry at 87°C to constant weight to obtain boride black phosphorus quantum dots; the mass ratio of black phosphorus quantum dots, ammonium pentaborate, Tween 20, and ethanol is 1:0.07:0.1:6;

[0045] Step S...

Embodiment 3

[0050] A membrane material for industrial wastewater treatment, formed by free radical polymerization of the following polymerizable monomers in parts by weight: 4.5 parts of vinyl-modified boronized black phosphorus quantum dots, vinyl-terminated hyperbranched poly(amine-ester ) 10 parts, β-phenylacryloyl chloride modified 2,4,6-tris(4-aminophenyl)-1,3,5-triazine 2 parts.

[0051] The preparation method of the vinyl-modified black phosphorus boride quantum dots comprises the following steps:

[0052] Step S1, put black phosphorus quantum dots, ammonium pentaborate, Tween 20, and ethanol in a polytetrafluoroethylene reaction kettle, keep warm at 160°C for 10 hours, cool to room temperature, remove ethanol by rotary evaporation, and then place in water Disperse, centrifuge, and dry at 90°C to constant weight to obtain boronized black phosphorus quantum dots; the mass ratio of the black phosphorus quantum dots, ammonium pentaborate, Tween 20, and ethanol is 1:0.1:0.1:7;

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com