Interface materials and methods of production and use thereof

a technology of interface materials and methods, applied in the direction of non-conductive materials with dispersed conductive materials, cable/conductor manufacturing, solid-state devices, etc., can solve problems such as difficulty in tasks, and achieve the effect of minimizing the size of the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

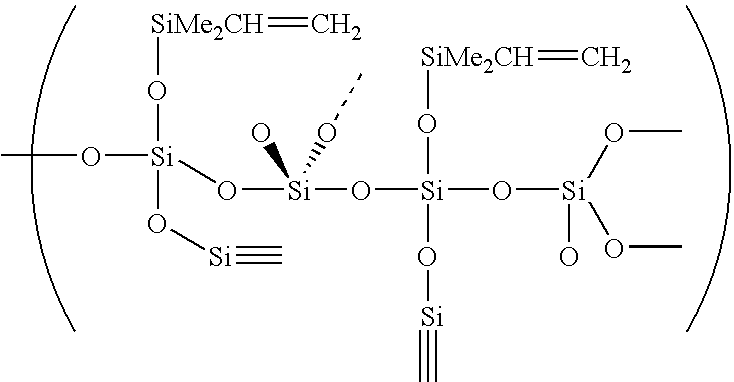

[0011] An interface material can be produced that comprises a resin mixture and at least one solder material. The resin material may comprise any suitable resin material, but it is preferred that the resin material be silicone-based comprising one or more compounds such as vinyl silicone, vinyl Q resin, hydride functional siloxane and platinum-vinylsiloxane. The solder material may comprise any suitable solder material or metal, such as indium, silver, copper, aluminum, tin, bismuth, gallium and alloys thereof, silver coated copper, and silver coated aluminum, but it is preferred that the solder material comprise indium or indium-based compounds.

[0012] As used herein, the term “metal” means those elements that are in the d-block and f-block of the Periodic Chart of the Elements, along with those elements that have metal-like properties, such as silicon and germanium. As used herein, the phrase “d-block” means those elements that have electrons filling the 3d, 4d, 5d, and 6d orbital...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com