Method for enhancing inner protection film hydrophilicity of polaroid

A technology of protective film and polarizer, which is applied in the direction of polarizing elements, can solve the problems of increased production costs, achieve the effects of reducing the pressure of environmental protection treatment, improving uniformity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

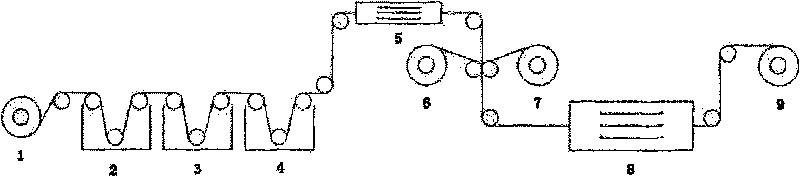

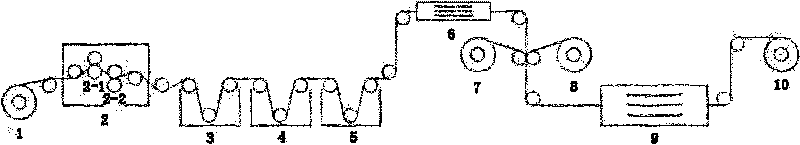

Image

Examples

Embodiment

[0067] Material Description:

[0068] Polarizer inner protective film: Triacetyl cellulose film (abbreviated as TAC film, the same below), produced by LOFO company in Germany;

[0069] Alkali: NaOH, commercially available, chemically pure;

[0070] Surfactant A: dodecyltrimethylammonium chloride, commercially available, chemically pure;

[0071] Surfactant B: cetyltrimethylammonium bromide, commercially available, chemically pure;

[0072] PVA (polyvinyl alcohol) film, product of Japan Kuraray Company, VF-P;

[0073] Adhesive: PVA aqueous solution (PVA-124: product of Kuraray Co.), concentration 5% (weight ratio).

[0074] Hydrophilic effect test:

[0075] Testing instrument: SL200A dynamic / static contact angle meter.

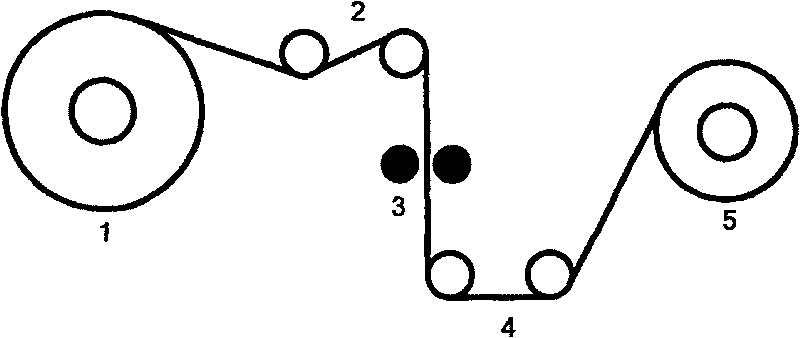

[0076] Detection method: In the environment of 25±1℃ / 60±5%RH, drop pure water on the surface of the film to be tested, and read the contact angle θ within 10 seconds (see Figure 6 , D is the film to be tested). 5 points were measured for each sample, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com