Polymerizable surfactant containing acrylic acid water-absorbent resin as well as preparation method and application thereof

A surfactant and water-absorbing resin technology, applied in the field of acrylic water-absorbing resin containing polymerizable surfactants and its preparation, can solve problems such as reducing dissolved oxygen in water, polluting water environment, and endangering aquatic organisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

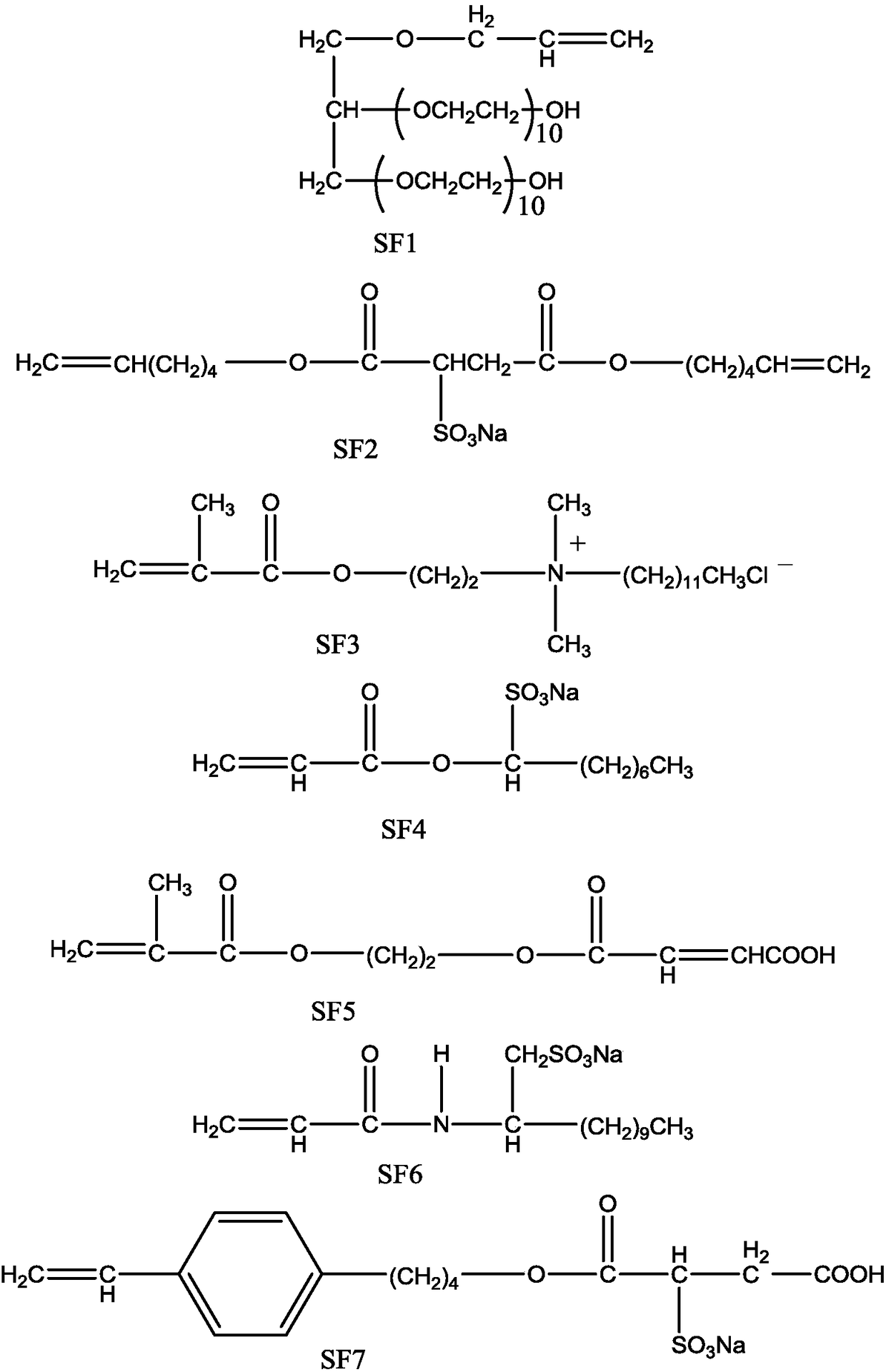

Method used

Image

Examples

Embodiment 1

[0036] a) Neutralization process: Dissolve 640g of sodium hydroxide solid in 4960g of water in the batching tank, then pour the aqueous solution of sodium hydroxide into a jacketed reactor with agitator, add 2400g of acrylic acid, and control the temperature in the reactor to 80 ℃.

[0037] b) Polymerization process: add 72g of polymerizable surfactant SF1 and 19.2g of pentaerythritol triacrylate to the neutralizing liquid obtained in step a), after stirring evenly, the neutralizing liquid in the reactor flows into the polymerization tank, and at the same time Add 192g of prepared 10wt% ammonium persulfate aqueous solution to the neutralization solution at the outlet of the reaction kettle, and obtain a hydrogel after polymerization for 15 minutes.

[0038] c) Drying process: Cut the hydrogel obtained in step b) into 2-20mm colloidal particles, then dry in an oven at 160°C for 140min, and then undergo crushing, grinding, and sieving processes in turn to obtain 150-800μm Prima...

Embodiment 2

[0041] a) Dissolve 1200g of sodium hydroxide solid in 3440g of water in the batching tank, then pour the sodium hydroxide aqueous solution into a jacketed reactor with a stirrer, add 3360g of acrylic acid, and control the temperature in the reactor to 80°C.

[0042] b) Add 0.336g of polymerizable surfactant SF2 and 1.68g of N, N-methylenebisacrylamide to the neutralizing solution obtained in step a), and stir the neutralizing solution in the reactor into the polymerization tank, At the same time, 16.8 g of a prepared 10 wt % potassium persulfate aqueous solution was added to the neutralizing solution at the outlet of the reaction kettle, and a hydrogel was obtained after 15 minutes of polymerization.

[0043] c) Cut the hydrogel obtained in step b) into 2-20mm colloidal particles, and then dry it in an oven at 160°C for 140min, and then go through the steps of crushing, grinding, and sieving in order to obtain a primary acrylic water-absorbing gel of 150-800μm resin powder.

...

Embodiment 3

[0046] a) 2880g of acrylic acid and 2880g of water are added to the kneader, then 14.4g of polymerizable surfactant SF3 and 11.52g of pentaerythritol triallyl ether are added, and after stirring evenly, 86.4g of a prepared 10wt% sodium persulfate aqueous solution is added , and polymerized for 2 hours at an initial temperature of 80°C.

[0047] b) granulate the polymer obtained in step a) in a granulator, and add 2240g mass concentration of 50% sodium hydroxide aqueous solution at the same time, obtain 2-20mm micelle from the granulator outlet, then at 160 ℃ Dry in a special oven for 140 minutes, and then successively undergo crushing, grinding, and sieving processes to obtain primary acrylic water-absorbing resin powders with a thickness of 150-800 μm.

[0048] c) Prepare a surface cross-linking auxiliary agent with ethylene glycol diglycidyl ether, aluminum sulfate, glycerin, and water at a mass ratio of 1:10:13:40, and make the surface of the primary acrylic water-absorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com