Automobile drive axle wheel-side planet axle with oil duct

A technology for planetary gear shafts and automobiles, applied in the direction of shafts, shafts and bearings, engine components, etc., can solve problems such as difficulty in lubricating oil, affecting the service life of drive axles, poor lubrication, etc., achieve good lubrication effect, reasonable structure, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

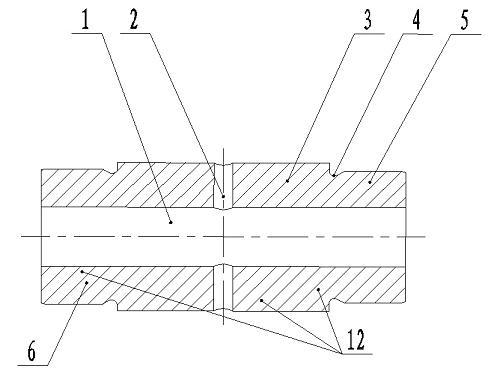

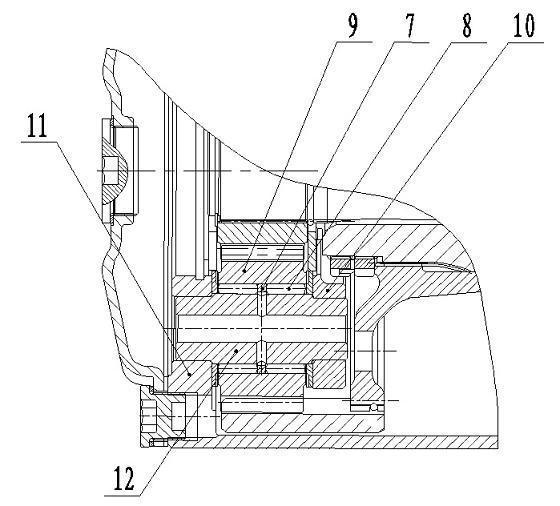

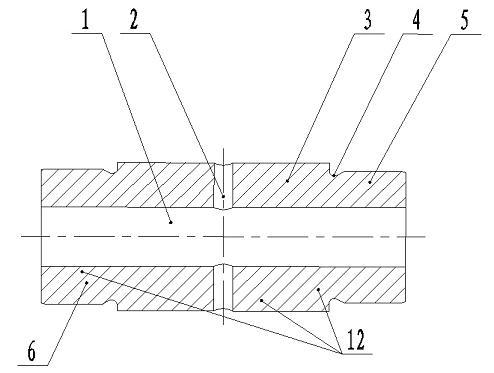

[0011] From figure 1 , figure 2 It can be seen from the figure that: a wheel-side planetary wheel shaft of an automobile drive axle with an oil channel, including a shaft body 12, is characterized in that: the left end section and the right end section of the long cylindrical shaft body 12 are stepped cylindrical sections, so that The shaft body 12 is successively from left to right a left step cylinder section 6, a shaft body section 3 and a right step cylinder section 5, and the diameters of the left and right step cylinder sections 6 and 5 are smaller than the diameter of the shaft body section 3. Grinding wheel overtravel grooves 4 are respectively provided at the junctions of the stepped cylindrical sections 6, 5 and the shaft body section 3 to facilitate grinding the outer peripheral surfaces of the left and right stepped cylindrical sections 6, 5 and the shaft body section 3. In addition, on the shaft An axial center through hole 1 is set on the body 12, and a radial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com