Powder coating type composite solid lubricant film preparation method and gear wheel with solid lubricant film

A powder coating and solid lubrication technology, applied in powder coatings, lubricating compositions, base materials, etc., can solve the problems of high concentration of organic volatiles, short wear life of dry film, etc., achieve long service life, good lubrication effect, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

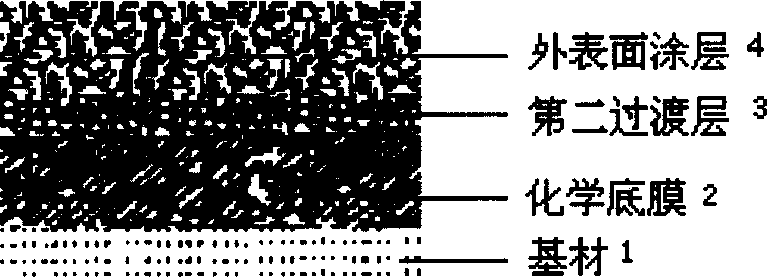

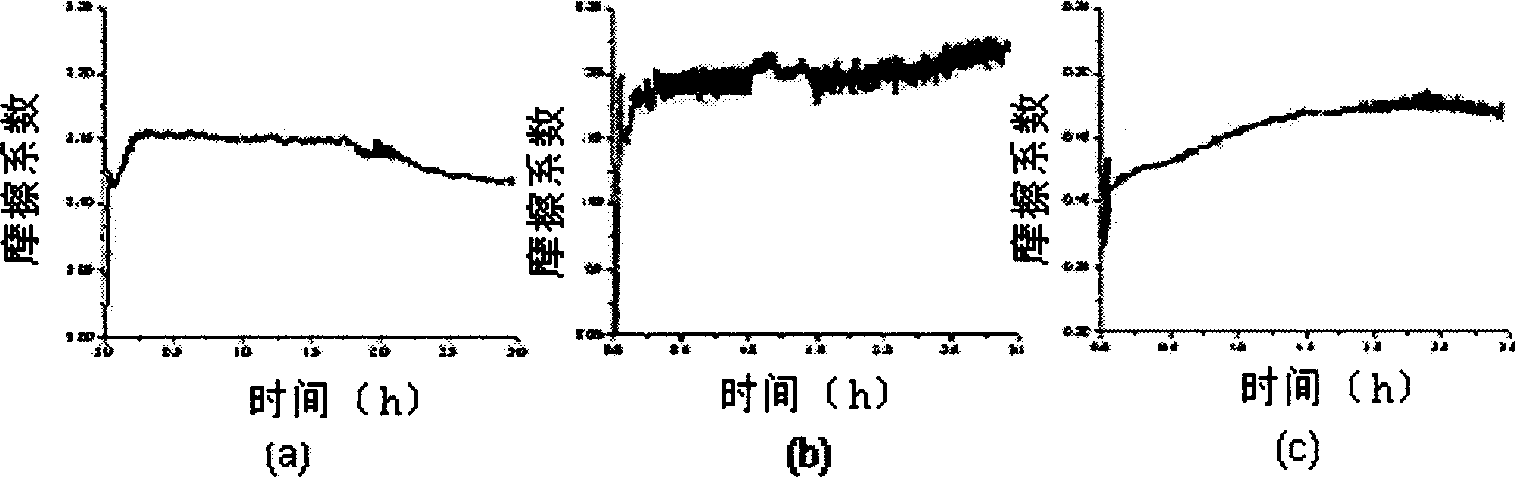

[0039] Embodiment one: see figure 1 with image 3 Figure (a).

[0040] Chemical base film treatment is carried out on the ring surface of the steel ring whose material 1 is 40Cr to form a phosphating layer 2 with a thickness of 6 to 10 μm, and then form 3 to 3 by rubbing one or several solid lubricants on the surface of the first transition layer. 5 μm thick second transition layer 3 . A polyester powder coating type solid lubricating film 4 with a thickness of 20-50 μm is coated on the annulus by means of electrostatic spraying and high-temperature curing. The curing conditions are: 180~220°C, 10~30min. In terms of mass percentage in the coating, the polyester resin CC440 is 30-85%, the curing agent TGIC is 3-40%, and the 3,5-di-tert-butyl-4-hydroxyphenyl octadecyl propionate is 3-5%. %, silicone leveling agent is 0.5-5%, benzoin is 0.2-1%, titanium dioxide and wollastonite are 3-25%, solid lubricant is molybdenum disulfide 3-20%, boron nitride 0-15% %, barium borate 0-1...

Embodiment 2

[0041] Embodiment two: see figure 1 with image 3 Figure (c).

[0042]Chemical base film treatment is carried out on the ring surface of the steel ring whose material 1 is 40Cr to form a phosphating layer 2 with a thickness of about 6-10 μm, and then form 3 by rubbing one or several solid lubricants on the surface of the first transition layer ~5 μm thick second transition layer 3 . A 20-50 μm thick epoxy powder coating type solid lubricating film 4 is coated on the ring surface by electrostatic spraying and high-temperature curing. The curing conditions are: 180~220°C, 10~30min. In terms of mass percentage, epoxy resin E12 is 30-85%, curing agent 284 is 3-40%, and 3,5-di-tert-butyl-4-hydroxyphenyl propionate is 3-5%. %, silicone leveling agent is 0.5-5%, benzoin is 0.2-1%, titanium dioxide and wollastonite are 3-25%, solid lubricant is molybdenum disulfide 3-20%, boron nitride 0-15% %, barium borate 0-10%, graphite 0-10%, molybdenum powder 0-10%, molybdenum oxide 0-10%, ...

Embodiment 3

[0043] Embodiment three: see figure 1 and image 3 Figure (b).

[0044] Chemical base film treatment is carried out on the ring surface of the steel ring whose material 1 is 40Cr to form a phosphating layer 2 with a thickness of 6 to 10 μm, and then form 3 to 3 by rubbing one or several solid lubricants on the surface of the first transition layer. 5 μm thick second transition layer 3 . A polyester / epoxy powder coating type solid lubricating film 4 with a thickness of 20-50 μm is coated on the annulus by means of electrostatic spraying and high-temperature curing. The curing conditions are: 180~220°C, 10~30min. In the coating, by mass percentage, the polyester resin P4127 is 30-85%, the curing agent epoxy resin E12 is 3-40%, and 3,5-di-tert-butyl-4-hydroxyphenyl propionate octadecyl alcohol is 3-5%, silicone leveling agent 0.5-5%, benzoin 0.2-1%, titanium dioxide and wollastonite 3-25%, solid lubricant molybdenum disulfide 3-20%, boron nitride 0-15%, barium borate 0-10%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com